-

ore milling process

process for milling ore – Grinding Mill China. Ball Mill For Grinding Iron Ore,Ball Milling,Ball Grinding Mill from Cement Making Machin process and the drum is equipped with wearresistant liner, which has good wearresista » Learn More Find jingxin jx JingXin Ball milling machine for stone /mineral ore 0086 for the machine Ball mill is the key equipment for .

Get Price -

Milling Ore | Wild Burro Processing

Milling Ore Once at the production facility, it is put through a hammer mill to reduce it down to 200 mesh minus in particle size, then fluxed and roasted to reduce ore to an oxide. It is then ball milled with steel balls to a nano particle size, to achieve the highest yield and also the highest concentration level of whatever metal or element is desired to be processed.

Get Price -

Mineral processing

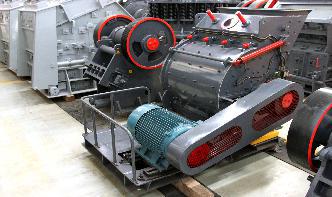

Crushing, a form of comminution, one of the unit operations of mineral processing. In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores .

Get Price -

Flowsheets

The process flowsheet was based on laboratory and pilotplant test work for milling flotation and calcine leach. Current focus for the project is away from the Panton process; Panoramic is investigating the potential for improved metallurgical recoveries and higher concentrate grades along with upgrade via ore sorting to produce a saleable highgrade concentrate ( Panoramic Resources, 2016 ).

Get Price -

Common Basic Formulas for Mineral Processing Calculations

· The control of a milling operation is a problem in imponderables: from the moment that the ore drops into the mill scoop the process becomes continuous, and continuity ceases only when the products finally come to rest at the concentrate bins and on the tailing dams.

Get Price -

Gold extraction

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting .

Get Price -

Ball Milling

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

Get Price -

Throughput optimisation in milling circuits

Each milling circuit is unique, and as such the goals and most optimal control strategy might differ for individual cases. Process IQ is an expert in implementing control systems for SAG and Ball milling circuits, making use of advanced stabilisation and optimisation strategies developed by Mintek.

Get Price -

Mining Process For Ironmining Process For Iron Ore

Iron Ore Processing Process Of Iron Mining Iron. Iron ore is an economic mineral aggregate containing iron elements or compounds. Four Kinds of Hematite Ore Dressing Processes Hematite (Fe2O3) is a kind of weak magnetic mineral, and its crystal belongs to the oxide mineral of hexagonal crystal system.

Get Price -

process for milling ore

Iron Ore Mill Scale Process Crushing Equipment For Sale. Recycling of steel plant mill scale via iron ore pelletisation process Abstract. Mill scale is an iron oxide waste . Chat Online. process of milling of iron oretvojesance . the ore is reduced to 3/4" or less it moves out of the mill in a slurry solution.

Get Price -

what is ore milling or processing

Stamp Mills for Processing Gold Silver Copper Ore . Stamps are built heavy made from steel or cast iron heavy enough to pulverize the ore beneath The stamps are repeatedly raised and dropped onto ore that is fed into the mill until the coarse ore is reduced to finer material capable of further processing The stamp mill provided an invaluable need for the early gold miners

Get Price -

Establishing thE ProcEss MinEralogy of gold orEs

process mineralogy. gold orEs and MinErals gold orE tyPEs Gold ores are commonly classified by the metallurgist into two major egories: freemilling and refractory ores. Typically, freemilling ores are defined as those where over 90% of gold can be recovered by conventional cyanide leaching. Refractory ores are

Get Price -

Ball Milling

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc .

Get Price -

Gold processing

· Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified. In this case they are merely shattered by .

Get Price -

Iron Processing

Our robust pug mills (paddle mixers) and rotary dryers are also frequently relied upon for processing steel byproducts in the form of dust and scale in order to liberate iron ore. Rotary dryers may also be used in ore drying appliions. We can also supply briquetters for briquetting sponge iron and hot briquetted iron (HBI).

Get Price -

Gold Process Mineralogy

process mineralogy address all issues related to gold ore processing by the detailed study of an ore or a mill product. The methodology is widely used as a predictive tool in feasibility studies and during the process development stage, and as a troubleshooting tool for mineral processing and hydrometallurgical operations. INTRODUCTION

Get Price -

process for milling ore

dry milling machines for gold ore processing. milling and grinding process pochiraju. Results 1 25 of 94 Grinding in Ball Mills Modeling and Process Control Cybernetics . Ore Milling ProcessGold Mining EquipmentMt. Baker Mining We are usually high in the drygrind process due to low value of DDGS 79/ton.

Get Price -

Establishing thE ProcEss MinEralogy of gold orEs

process mineralogy. gold orEs and MinErals gold orE tyPEs Gold ores are commonly classified by the metallurgist into two major egories: freemilling and refractory ores. Typically, freemilling ores are defined as those where over 90% of gold can be recovered by .

Get Price -

Processes

Processes. Copper is found in natural ore deposits around the world. This page explains the production route taken from extraction of orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in a wide variety of appliions essential to .

Get Price -

Optimization of the tantalum ore production by control the ...

milling and separation ore processing technologies for Tungsten and Tantalum mineral processing, by means of improved fast and flexible fine tuning production process control based on new software models, advanced sensing and deeper process physical study increasing yield in 712% on the current best production ...

Get Price -

MILLING CONTROL OPTIMISATION

ore treated was very difficult to mill. In the first two days, the mill experienced numerous power dips (overloads), and on at least seven occasions the feed to the mill had to be completely stopped to grind the mill out. Also, the mill load varied in the range of 125 to 165 tons. These disturbances propagated throughout the milling circuit and ...

Get Price