-

Properties of concrete made with crushed concrete as ...

Tests on the aggregates showed that the recycled concrete aggregates have lower specific gravity and higher absorption capacity than the original crushed granite aggregate. The resistance to mechanical actions such as impact, crushing and abrasion for the recycled concrete aggregates is also lower.

Get Price -

Different Types Of Aggregate And Their Uses

The Different Types Of Aggregate. The egories of aggregates include gravel, sand, recycled concrete, slag, topsoil, ballast, Type 1 MOT, and geosynthetic aggregates (synthetic products commonly used in civil engineering projects used to stabilise terrain). Let's detail a few of them. Crushed Concrete

Get Price -

Aggregate Crushing Strength Test

12/07/2021 · The crushing strength or aggregate crushing value of a given road aggregate is found out as per IS2386 Part 4. The aggregate crushing value provides a relative measure of resistance to crushing under a gradually applied compressive load. To achieve a high quality of pavement aggregate possessing low aggregate crushing value should be preferred.

Get Price -

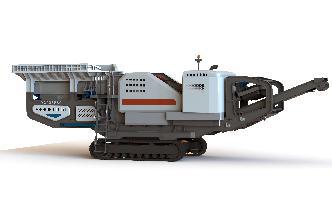

Crushing Screening Plant Design Factors

14/04/2016 · Crushing Plant Design and Layout ConsiderationsCrushing Circuit "A'' shows a small simple layout for use in mills up to 100 tons. In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or vibrating grizzly ahead of the crusher and then crushing ...

Get Price -

IS 23864 (1963): Methods of test for aggregates for ...

aggregate crushing value of coarse aggregate. NOTE 1 The 'aggregate crushing value' gives a relative measure of the resistance of an aggregate to crushing under a gradually applied compressive load. With aggre gate of 'aggregate crushing value' 30 or higher, the result may be anomalous, and in

Get Price -

Aggregate | What Is Aggregate | 17 Types Of Aggregates ...

The Recycled aggregates properties may be different accordingly types of concrete because the parent concrete was designed for its purposes such as permeable, durable and high strength concrete. Aggregate recycling is a simple process there is no complex method involved. The recycling method includes breaking, removing, and crushing existing concrete into a material .

Get Price -

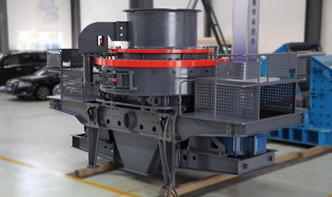

What are the Different Types of Aggregate Crushers?

Gyratory crushers are also used as aggregate crushers. These types of crushers are similar to jaw crushers, but employ a cone shaped hopper with a smaller coneshaped crushing head that gyrates around the inside of the hopper in an eccentric movement rather than rotating, crushing the source material until the particles are small enough to fall through the opening at the bottom.

Get Price -

Aggregates for Concrete

Crushed stone is produced by crushing quarry rock, boulders, cobbles, or largesize gravel. Crushed aircooled blastfurnace slag is also used as fine or coarse aggregate. The aggregates are usually washed and graded at the pit or plant. Some variation in the type, quality, cleanliness, grading, moisture content, and other properties is expected.

Get Price -

Aggregate Crushing Plant | PDF | Construction Aggregate ...

Basic Parts of Aggregate Crushing Plant Usually Crusher machine includes following machines: 1. Vibrating Feeder 2. Jaw Crusher 3. Impact Crusher 4. Vibrating Screen 5. Belt Conveyor. PLAY VIDEO: 2 Vibration Feeder A vibratory feeder is an instrument .

Get Price -

Importance Of Aggregate Crushing Value Test

Aggregate Crushing Value Civil Engineering Portal. This test helps to determine the aggregate crushing value of coarse aggregates as per IS: ... i want to know the importance of impact value of coarse aggregate. Read more

Get Price -

(PDF) AGGREGATE CRUSHING PLANT | Birhanu Shiferaw ...

AGGREGATE CRUSHING PLANT. ADDIS ABABA UNIVERSITY INSTITUTE OF TECHNOLOGY SCEE, May 2016 1. Introduction General Aggregates are one of the important constituents of concrete that comprises up to 75 percent of concrete. They are considered as inert fillers in concrete but play important roles in the behaviors both freshly .

Get Price -

Aggregate Crushing Value Test – Determine Aggregate ...

17/05/2019 · Aggregate crushing value is defined as the percentage by weight of the crushed (or finer) material obtained when the test aggregates are subjected to a specified load under standardized conditions, and the strength of the aggregate used in road construction is expressed by numerical index. Aggregates with lower crushing value show a lower ...

Get Price -

Grading of Aggregate | Ultimate Guide

11/04/2020 · Any aggregate particle that retains of sieve #4 is called 'coarse aggregate'. Coarse aggregates (also known as crushed stones) are majorly added in the concrete mix for strength gain purposes. They can be obtained by blasting heavy rock boulders. In Pakistan, we generally use Margalla Crush, Sargodha Crush and Sakhi Sarwar Crush

Get Price -

Influence of Crushed Coarse Aggregates on Properties of ...

Both coarse aggregates and fine aggregates are the main constituents of concrete because they not only give the body to the concrete, it also have a significant effect on the fresh concrete based on aggregate's shape, size, texture, grading and crushing type. Moreover it is proved that aggregate's types has the severe effect on physicmechanical properties of concrete as aggregate covered ...

Get Price -

Understanding Effects of Crushing Mechanism on Aggregate ...

25/10/2019 · The aggregates were collected from two different types of crushers (i) the first crusher had jaw, cone and vertical shaft impactor (VSI) as primary, secondary and tertiary crushers, respectively; and (ii) the second crusher had jaw, horizontal shaft impactor (HSI) primary and secondary crushing unit, respectively.

Get Price -

What are the Different Types of Aggregate Crushers?

Aggregate crushers are used to produce crushed stone for landscaping. Jaw crushers are the aggregate crushers that are most often employed in large mining or quarrying operations. A jaw crusher is designed to crush large pieces of ore or rock between two plates or jaws. One jaw is stationary, and the other is mounted so that the two jaws form a ...

Get Price -

Aggregate Rock Crushing Operations

Aggregate and rock crushing operations involve the handling and processing of nonmetallic mineral products for the construction industries. Nonmetallic mineral products are quarried or mined and are then transported to the processing plant for further classifiion and/or further size reduction.

Get Price -

METHOD B1 THE DETERMINATION OF THE AGGREGATE CRUSHING ...

The aggregate crushing value (ACV) of an aggregate is the mass of material, expressed as a percentage of the test sample. which is crushed finer than a 2,36 mm sieve when a sample of aggregate passing the 13,2 mm and retained on the 9,50 mm sieve is subjected to crushing under a gradually applied compressive load of 400 kN. 2 APPARATUS

Get Price