-

Milling Cutter: Definition, Types in detail, Geometry ...

Cylindrical Mill Cutter is the type of cutter which has a cylindrical shape and has teeth on the circumferential surface only. 9. Hollow milling cutter: It looks like a pipe having thicker walls. The cutting teeth of the hollow mills on the inside surfaces. This cutter used in .

Get Price -

Profile milling

#160; Profile milling is a common milling operation. Round inserts and concepts with radius are milling cutters used for roughing and semiroughing while ball nose end mills are milling cutters used for finishing and superfinishing. #160; Profile milling process Profile milling covers multiax...

Get Price -

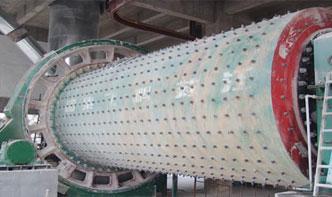

Wet Grid Ball Mill

Wet Grid Ball Mill | Capacity: Feed Size: ≤25 mm. Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm.

Get Price -

Stainless Steel Finishes Explained

Sep 13, 2019 · The resulting stainless steel finish is capable of reflecting clear images. It is very smooth and less likely to harbour airborne contaminants and moisture compared to any other mill finishes. This easytoclean finish has a typical Ra between . micrometers. The 2R, also known as BA stainless steel, is commonly used for domestic ...

Get Price -

VRM vs Ball Mill for Cement Grinding

Feb 10, 2016 · VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 – TPH) and before implementing the project, we would like to

Get Price -

End Mills. The Essential Beginners Guide.

End Mills. 1. End Mills cut rotationally in a horizontal, or lateral (side to side) direction whereas a drill bit only cuts straight down, vertically into the material. 2. Endmills are available in a wide variety of lengths, diameters, flutes and types, and are chosen according to the material they are cutting and the surface finish required ...

Get Price -

CNC Milling Vs. Manual Milling

CNC Milling Vs. Manual Milling. Different fields in the manufacturing industry rely heavily on machining. Whether you are considering starting a machining business or looking to have components for your next project produced, you need to decide whether you are going for CNC machining or manual machining.. Even though CNC milling has eclipsed manual milling with .

Get Price -

Advantages Of Vertical Roller Mill Over Ball Mill

Advantages And Disadvantages Vertical Milling Machine. Nov 07, 2013 The vertical roller mill is widely used in the mining industry, there are many advantages of vertical roller mill, So its welcomed by many customers. l High efficiency Under the same finished final size and the same motor power, the capacity of stone micronizer is twice as much as jet mill, mixing grinder and ball mill.

Get Price -

Milling Process, Defects, Equipment

6. Possible Defects. 7. Design Rules. 8. Cost Drivers. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling machine, workpiece, fixture, and cutter. The workpiece is a piece of preshaped material ...

Get Price -

Projects and Articles on Our Forum! | The HobbyMachinist

Apr 11, 2019 · 11,063. 20. I picked up a Clausing variable speed drill press from a Craigslist ad. I offered the guy and he accepted. The drill press was in decent overall condition, and had a new motor on it. I disassembled the machine and cleaned up and painted everything.

Get Price -

How to use a Milling Machine

The plain vertical machines are characterized by a spindle loed vertically, parallel to the column face, and mounted in a sliding head that can be fed up and down by hand or power. Modern vertical milling machines are designed so the entire head can also swivel to permit working on angular surfaces.

Get Price -

Coal mill, gypsum mill, clay mill, etc. | Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements. The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unit.

Get Price -

Impact Crusher | Stone Crusher used for Ore Beneficiation ...

Feb 03, 2012 · The grate baskets calibrate the material grain size by different openings, in order to produce raw material either for ball mills (0/25 mm) or vertical mills (0/80 mm). Double Shaft Hammer Crushers are used in the cement industry to solve crushing problems in difficult materials like wet limestone combined with clay.

Get Price -

Choose Ball Mill Or Vertical Mill

Ball Mill Vs Vertical Roller Mill. May 05, 2020 There are many differences between vertical roller mill and ball mill,not only in production equipment to choose depends on your actual production efficiency, site and budget.

Get Price -

CHAENGMining Equipment Suppliers

Cement Ball Mill. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores. Cement ball mill is not only suitable for overflow grinding.

Get Price -

What Is Face Milling and Why Should You Bother?

Face milling, in general, is defined as the process of cutting surfaces that are perpendicular to the cutter axis, or the faces of a part. Shell mills and fly cutters are most often used for face milling, but depending on what kind of surface finish you're looking for, you could use an end mill as well. YouTube.

Get Price -

How it Works: Crushers, Grinding Mills and Pulverizers ...

Jun 02, 2017 · Ball mills vary greatly in size, from large industrial ball mills measuring more than 25 ft. in diameter to small mills used for sample preparation in laboratories. Rod mills are similar to ball mills and use metal rods as the grinding media. Pebble mills use rock pebbles as the grinding media to cause friction and attrition between the pebbles ...

Get Price -

Standard Machining FAQs – Sherline Products

It also includes a mill headstock spacer block which adds 11/4″ to the throat distance (clearance between the tool and the vertical column). With the addition of the horizontal milling conversion, surfaces up to 6″ x 9″ can be machined without moving the part. This is a very large machinable area for a tool of this compact size.

Get Price -

Milling Cutters Tools

Feb 21, 2020 · The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. ... Ball cutters, also known as ball mills, have a hemispherical cutting tip. The objective is to maintain a corner radius for perpendicular faces. Slab mill.

Get Price -

Crusher Mills, Cone Crusher, Jaw Crushers

CrusherMills: Heavy Industry Rock Crushers. At CrusherMills, we have a superior line of rock crushing machines standard rock crushers, jaw crushers, cone crushers, stone crushers, grind mills, ball mills as well as imapct, gyratory, and roller style rock crushers.

Get Price -

Clinkerization

Raw meal enters (at 50 0 C) in the riser duct of second cyclone (from top) and is picked up with the hot gases to first (top) cyclone, where raw meal is separated from gas stream and passed down to second cyclone. Heat transfer takes place in suspension phase between hot gases and raw meal.

Get Price -

Chapter 18. Feed Milling Processes

Fig. 1 Hammer Mill. Attrition Mills. Attrition mills use the hammermill principle to a certain extent;, shattering by/impact. However, they also impart a shearing and cutting action. Grinding is done between two discs equipped with replaceable wearing surfaces. One or both of these discs is rotated; if both, they rotate in opposite ...

Get Price