-

Effect of dry grinding on the physicochemical properties ...

· The present study evaluates the effect of dry grinding on the physicochemical properties of silica materials prepared from kaolin residue. The kaolin residue was ground at varying times and then treated with sulfuric acid (20 mass%) at 100 °C for 2 diffraction, scanning electron microscopy, Fourier transformation infrared spectroscopy, and N 2 adsorption techniques were used .

Get Price -

A Study On Fine Grinding Process Of Silica In Planetary Mill

Read A STUDY ON FINE GRINDING PROCESS IN JET MILL. A study on ultra fine grinding of silica and talc in opposed fluidized bed jet MILL. mill, stirred mill, jet mill and planetary mill experienced mechanochemical effect during the fine grinding process, which agrees with Table

Get Price -

Silica Sand Washing Plant | Quartz Sand Processing | MC

Silica sand washing plant mainly includes: quartz stone crushing and sand making, washing, grading, desliming, scrubbing, magnetic separation, flotation, acid leaching and other processes to remove the small amount or micro amount of impurities in silica sand and obtain refined silica sand or highpurity silica sand for glass, ceramics, construction, chemical and other industries.

Get Price -

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

7 Cement grinding and storage In this unit, the input materials (Clinker, Gypsum, Pozzolana, and Limestone additive) are proportioned and ground in Cement mill (one Closed circuit ball mill in line 1 and two Roller press+closed circuit ball mill in line 2) based on the type of

Get Price -

China Dry Grinding Ball Mill for Fine Powder Drying Silica ...

Dry Grinding Ball Mill for Fine Powder Drying Silica Ball Mill Zoneding ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacture industries, such as cement, silie, new building material, refractory

Get Price -

Clint Fletcher

Alternating positions in the concentrator division to include mill control room, crushing, ore transportation, tailings, grinding and flotation plants. Supervised an average of 17 employees per shift.

Get Price -

CERAMIC MATERIALS I

Fine grinding or milling reduces the particle size down to as low as micrometer (μm) (4 x 105 in.) in diameter. Ball mills are the most commonly used piece of equipment for milling. However, vibratory mills, attrition mills, and fluid energy mills also are used.

Get Price -

WalkBehind Milling Machines and Floor Grinders

amount of silica dust that becomes airborne when milling or grinding silica containing materials because it controls the exposure at its source. The silica standard specifies the use of walkbehind milling machines and floor grinders that are equipped with an integrated water delivery system that continuously delivers water to the cutting surface.

Get Price -

Silica sand processing plantSinonine

Sinonine silica sand processing plant remove the impurities such as iron, aluminum trioxide, mica etc through crushing, scrubbing, washing, classifying and beneficiation. Quartz raw ore or quartz/silica sand needs to be purified to remove impurities so .

Get Price -

grinding mill machine colombo thomas the tank rock

Grinding Machine Saleser In Colombo drkaniade. Grinding machine saleser in colombo Mobile Crushers all, grinding machine saleser in colombo heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill ...

Get Price -

Attention To Silica Sand Grinding Mill

Therefore, the silica sand grinding mill should be maintained and cleaned regularly to remove the dust and other impurities, so as to ensure the efficient operation of the equipment next time. On the whole, the operation efficiency of silica sand grinding mill is still very high, but in the production process may encounter a variety of problems and failures, which requires timely maintenance ...

Get Price -

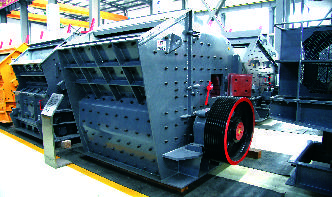

Ball mill grinding plant with classifier for Silica and ...

· At, our ball mill grinding plant with classifier sent to Egypt to grind Silica and Feldspar Powder. It will be installed in Sadat City of Egypt. The assembly of ball mill plant is *8M Ball mill plant+ ASS830 classifier+XMC706 bag dust cher, it will be used to produce 100 micron, 45 micron and 38 micron silica and feldspar powder, to be used in ceramic industry.

Get Price -

INTRODUCTION GUIDELINES

Grinding beads #2168 Silica, low binding grinding beads #2181 Zirconium low binding grinding beads Prefilled vials # 100μm Silica beads, grade #AW 100μm acid washed Zirconia beads Complex Matrices – Soil, Feces, Biofilms

Get Price -

mineral processing silica grinding ball mill for aluminium ...

Silica grinding machine, Silica grinding equipment,Ball Ball mill is an efficient tool for grinding silica sand into silica powder There are two ways of grinding: the dry process and the wet process It can also be divided into tabular type and flowing type according to different forms of discharging material Ball mills are widely ...

Get Price -

Home | AMK

Specialist in Grinding, ... Air Classifier Mill (ACM) Already Installed in 2015 For Carrageenan Product . Nauta Mixer Already Installed in 2016 ... For The Silica Sand Industry. view all. PT ANUGRAH MANDIRI KARYATEK +62 21 2917 7566 / 538 5267 or Contact Us About Us. We are a ...

Get Price -

How Milling Contractors Can Comply with OSHA's Silica ...

· In 2020, OSHA intends to target roadway construction activities, specifically milling activities, to identify and reduce worker exposure to silica dust; Here's how to comply

Get Price -

Mill Creek, OK | Silica

Mill Creek, OK. Plant. 4800 Oklahoma Highway 1 North. Mill Creek, OK 74856. (800) . Get Directions. Need Help? Let us help you find the right product solution. Need Help?

Get Price -

(PDF) Photoisomerisation behaviour of azobenzene crystals ...

The Az–silica hybrids (, and ) were subjected to beadmilling in a PVA solution to prepare aqueous dispersions in the same manner as used for Az crystals.

Get Price