-

IRON AND STEEL RECYCLING

Integrated steel mills consumed about 16 Mt of iron and steel s crap an d 400,000 t of DRI in blas t an d bas ic ox ygen furnaces durin g 1998. Min imills that use electric arc f urnaces consumed about Mt of pig iron and about 42 Mt of scrap during 1998. Thus, steel scrap comprised about 43% of iron units supplied for steelmaking.

Get Price -

Energy Balance of Steel Mills and the Utilization of By ...

at steel mills are generally as shown in Table 1, with some variation depending on properties of coking coal and the operational conditions of coke oven, blast furnace and BOF. 2. General Description of Various Byproduct Gases (1) Coke Oven Gas (COG) Coke oven gas is obtained ...

Get Price -

IRON, STEEL AND BASE METAL PRODUCTION IN MYANMAR

township, paraphrased from an article in Business Tank, gives a firsthand impression of the entrepreneurial spirit of the smallscale metal producer in Myanmar. The only mills in the country capable of processing crude iron are the small factory at Anisakhan near PyinULwin, the Ywama steel mill at Insein and the mill belonging to the ...

Get Price -

Introduction to Milling Tools and Their Appliion

End mills are made out of either cobalt steel alloys (known as high speed steel, or HSS), or from tungsten carbide in a cobalt lattice (shortened to "carbide"). High Speed Steel (HSS): Provides good wear resistance and costs less than cobalt or carbide end mills. HSS is used for general purpose milling of both ferrous and nonferrous materials.

Get Price -

CHICAGO'S SOUTHEAST SIDESOUTHEAST SIDE Industrial History

Steel mills, grain elevators, related businesses lined the river taking advantage ofbusinesses lined the river taking advantage of the cheap transportation it offered. The heyda y of the area was probably from about 1900 to 1970. The decline of the steel industry followed and peaked with the closings of Wisconsin

Get Price -

Treatment of steel rolling mill ...

Research Article Open Access harma and hasarwar, Chem Eng rocess Technol, 9 / Research Article Open Access Treatment of Steel Rolling Mill Effluents Using SemiBatch Flotation Varun Sharma and Ashok N Bhaskarwar* Department of Chemical Engineering, Indian Institute of Technology, Hauz Khas, New Delhi, India

Get Price -

MILLING OPERATIONS TYPES OF MILLING MACHINES

Milling cutters are usually made of highspeed steel and are with its parts and angles identified. These parts and angles in available in a great variety of shapes .

Get Price -

ASTM Standard List

ASTM specifiions represent a consensus among producers, specifiers, fabriors, and users of steel mill products. ASTM's designation system for metals consists of a letter ( A for ferrous materials) followed by an arbitrary sequentially assigned number.

Get Price -

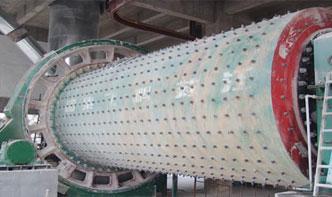

Ball Mills

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Get Price -

PAPER OPEN ACCESS 2020 Technology and Operation of a Hot ...

· Transfer bar cooling system installed at the hot strip mill of Tata Steel´s Port Talbot [2]. Whereas transfer bar cooling is installed on HSM's [1,2], induction heating is more frequently used for mini mills, that is, combined casting hot rolling lines [3, 4]. Transfer bar cooling is installed just after the roughening mill.

Get Price -

STRUCTURAL STEEL TERMS/ LAYOUT AND FABRICATION OF STEEL ...

Figure 34.—Weight and thickness of steel plate. sheet, or plate, according to the thickness of the material, the width of the material, and (to some

Get Price -

Steel Grades, Properties and Global Standards

4 Steel Grades, Properties and Global Standards *designation according to Stahl Eisen Liste (Register of European Steels). 1also available as EDX 2304™ with enhanced available as S31803. 3724L is a modifies version of 4435 for Urea not available in all product available as available as 317L with

Get Price -

Metalfer Steel Mill

Metalfer doo (herein "Metalfer") has been established in Serbia in 2002 in order to develop the Group's operations in the Balkans. Ever since, the company grew to become one of the major steel and mining players in the region.

Get Price -

QB 21602 2021 2QTR Absolute Steel Mill Articles ...

01/04/2021 · COMMODITY:Steel Mill Articles as specified in Presidential ProclamationsQUOTA PERIOD:April 1, 2021 through June 30, 2021OPENING:April 1, 2021 12:01 AM Local Port entries submitted prior to 8:30 am ET April 1, 2021 will be counted in the first opening at 8:30 am ET. Entries submitted prior to April 1, 2021 local port time will not be counted towards the .

Get Price -

Quality Assurance Workshop Steel Mill Quality (QC Process ...

Steel Mill Quality (QC Process and Issues) Mill Defects Defects in steel products are defined as deviations in appearance, shape, dimension, macrostructure / microstructure, and/or chemical properties when compared with the specifiions given in the technical standards or any other normative documents in force.

Get Price -

RICE MILLING

Rice Milling Poonam Dhankhar (Food tech), . T, Hissar, Abstract: The Rice milling is the process that helps in removal of hulls and bran's from paddy grains to produce polished rice. Rice is rich in genetic diversity with thousands of varieties grown throughout the world. Rice has been one of man's most important foods.

Get Price -

SIMA Steel Tables

SIMA Steel Tables. Download. Choose which SIMA static file you would like to download below: Note: SIMA Monthly License files refer only to License data and the other files incorporate Census and License data. The wide files display the data horizontally (both, quantity and value) and the long files display data vertically.

Get Price -

Steel Pipe Manufacturing Processes

Steel Pipe and Manufacturing Processes Introduction. The advent of rolling mill technology and its development during the first half of the nineteenth century also heralded in the industrial manufacture of tube and pipe. Initially, rolled strips of sheet were formed into a circular cross section by funnel arrangements or rolls, and then butt or ...

Get Price -

MACHINING OPERATIONS AND MACHINE TOOLS

3. Milling • Milling – A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine) • Types – Peripheral milling • Slab, slotting, side and straddle milling • Up Milling (Conventional) down milling (Climb) – Facing milling • Conventional face, Partial face, End ...

Get Price -

General Catalog of TOOL STEELS

High speed steel with high abrasion resistance and toughness for general use. High speed steel to prevent from abrasion, seizure and deformation under high pressure Cold forging dies, cold heading dies, slitter. Matrix high speed steel, extremely highest toughness in .

Get Price -

How Just 14 People Make 500,000 Tons of Steel a Year in ...

· The plant, a twohour drive southwest of Vienna, will need just 14 employees to make 500,000 tons of robust steel wire a year—vs. as many as 1,000 in .

Get Price -

CO2 Emission Reduction Potential in the Steel Industry by ...

cluding a direct reduction process (DRP) into a fully integrated steel mill was investigated. Therefore, a blast furnace model, derived from literature data and implemented in Aspen Plus, was used to analyze the impact of DRI in the blast furnace process. Furthermore, a stateoftheart DRP was modeled to investigate the possibility of ...

Get Price