-

Optimization of continuous ball mills used for finish ...

During the last decade, semifinishgrinding plants have been used more and more for the energy efficient grinding of highquality cement. In 1999, it was found that by decreasing the ball charge filling ratio it was possible to lower the specific energy demand for grinding significantly.

Get Price -

Batch Mill Grinding VS Continuous Grinding Compared

· Batch Mill Grinding VS Continuous Grinding Compared. Post navigation. Previous. Next. When the amount of ore in the mills was the same, no appreciable difference between batch and continuous opencircuit ballmill grinding was found. This should be so, because the progression in particle size for the duration of a batch run would be expected to .

Get Price -

Food milling Equipment

Ball or roller mill solutions may improve how you refine your chocolate. We can also offer grinding solutions for coffee beans, varying from traditional mortar grinding to stone, hammer or roller mills. We have premilling solutions for nuts, spices, soya beans, mustard, chili, meat pastes, juices and can help you mill vegetables and fruits. Air classifier or fine impact mills may be best to ...

Get Price -

Biobase Laboratory mills

Planetary Ball Mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed ...

Get Price -

Remas Redüktör ve Makina

REMAS REDUKTOR VE MAKINA SANAYI has been serving the worlds heavy industry since1966. Our newest manufacturing plant with facility sits in at the TepeorenTuzla industrial zone i...

Get Price -

Grinding Crushing Mill

Each grinding mill is achieving impressive energy savings (3550%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary grinding mills. New processes such as micron grinding and mechanochemical grinding give our customers a unique and effective competitive advantage.

Get Price -

continuous ball mill for grinding

elogue continuous ball mill for grinding elogue continuous ball mill for grinding. elogue continuous ball mill for grinding. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silies, refractory material, fertilizer, glass ceramics, etc. as well as get price

Get Price -

Ball Mill | Ball Mills | Wet Dry Grinding | DOVE

DOVE Ball Mills are supplied for a wide range of appliions, for either wet or dry grinding, for both Batch and Continuous operation, as well as open and Closed Circuit Ball Milling Process. • BALL MILL BALLS (GRINDING BALLS): DOVE Ball Mills are designed to operate with various types of grinding media (Grinding Balls), DOVE supplies various types and sizes of Ball .

Get Price -

Outotec ® Grinding technologies

Outotec Grinding technologies 003 Ø28' Ball Mill 14,000 kW installed power . Open the alog to page 3 . 004 Outotec Grinding technologies A full range of mills for wet and dry grinding The demands of hard rock mining and industrial minerals operations require a diverse range of grinding mills for both wet and dry appliions. AG and SAG mills are currently the industry standard for ...

Get Price -

elogue continuous ball mill for grinding

elogue continuous ball mill for grinding. Dry continuous grinding ball mill and wet latticetype continuous grinding ball mill can be selected according to . Get Price continuous ball mill hs code mkrdrpolytechnic. Ball mill Wikipedia, the free encyclopedia continuous ball mill hs code,A ball mill is a type of grinder used to grind, Highquality ball mills are potentially . Get .

Get Price -

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the ...

Get Price -

Continuous Ball Grinding Mill

Elogue continuous ball mill for grinding. elogue continuous ball mill for grinding. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silies, refractory material, fertilizer, glass ceramics, etc. as well as. Ball Mill Continuous Grinding Ball Mill Crusher Mills. Ball Mill,Ball Mills,Ball .

Get Price -

EVRAZ To Increase Grinding Balls Production By 30%

The product offering will feature steel grinding balls with diameters ranging from 80 to 130 mm; they will be hotrolled from continuously cast vacuumtreated ingots. The project envisages production of larger balls of superior hardness with wear resistance and surface hardness in line with the best imported comparables. "With the new mill in place, we will make a breakthrough .

Get Price -

Calculate and Select Ball Mill Ball Size for Optimum Grinding

· In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner .

Get Price -

Ball Mills

Catalog; Operating Manuals; Ball Mills. Home. Products. Ball Mills . Our Ball mills are designed for mining and mineral processing industry, for grinding the ore to the expected size for the next stage beneficiation process. We also supply the laboratory and pilot scale ball mills for mineral beneficiation laboratory test. Ball Mill Shell. Ball mill shell is a large steel part made of steel ...

Get Price -

Grind

Balls for use in mineral processing ball milling operations are designed for maximum abrasion resistance using high carbon content and high hardness levels. PRODUCT SPECIFICATIONS. SIZE Molycop manufactures forged grinding balls for use in ball milling and regrind appliions in nominal sizes from " to " in diameter. CHEMISTRY An individual chemical profile has .

Get Price -

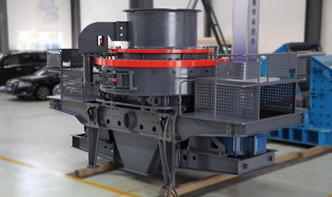

Continuous Ball Mill | Continuous Type Ball Mill for ...

Grinding medium: High aluminum ball. Appliions: Continuous ball mill is the key equipment for dry or wet grinding of silie products, new building materials, refractory materials, fertilizers, ferrous and nonferrous metals and glass ceramics and other industries. Email: info Get Price Now. Product Details.

Get Price -

Optimization of continuous ball mills used for finish ...

· Furthermore, it has shown that a L/D ratio of about, which is a quite common value for cement mills, might be to high for a ball mill in a Combigrinding plant. This was proven by the fact that there was no grinding progress observed in the last third of the total grinding path length. This finding was not effected by different ball charge filling ratios and different mill .

Get Price -

Ball Mills

· Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume. Mills are shipped with liners installed. Ceramic linings are designed for .

Get Price -

Combination Continuous/Batch Rod and Ball Mill | Sepor, Inc

Sepor's 16 x 32 continuous ball or rod mill is ideal for pilot plant studies or small scale milling. The unique hinged 'torpedo tube' end plate on the discharge side allows the unit to be changed from continuous to batch mode within minutes. In continuous configuration, it can be combined with a Sepor spiral classifier, screens or cyclones to provide closedcircuit grinding. As a .

Get Price -

continuous ball mill dry grinding

Ball Mill RETSCH powerful grinding and homogenization. The high energy ball mill e max and mm were developed for grinding with the highest energy input the innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects these ball mills are also suitable for mechano chemistry

Get Price -

elogue continuous ball mill for grinding

» Catelogue Continuous Ball Mill For Grinding » washing sand machine in saudi » brick moulding machine for sale in sa » crushing plant fop korea » vertical crusher polymers system » aggregate and mining » powerstone boat parts india » mobile crushers in fife » price of copper ash. elogue continuous mill for grinding . Recent Posts. continuous ball mill wet grinding; continuous ...

Get Price -

Mills » Products » CEMTEC

Ball mills for wet and dry grinding appliions CEMTEC offers grinding solutions with ball or pebble mills for wet or dry appliions with an open or a closed grinding circuit. The mills are available with either a slide, slide shoe, or spherical rol ler bea ri ng, as well as with either gear rim/pinion, direct, or central drive; they can have a rubber, steel, or ceramic lining.

Get Price -

Catelogue Continuous Ball Mill For Crusher

Catelogue continuous ball mill for grinding Manufacturer,Ball Mill Machine Continuous Ball Mills grindi A special case of the grate ball mill is known as the pebble mill Media include porcelain balls Nonmetallic such as flint pebbles and sometimes the ore itself When the ore itself is used as media, the mill is termed autonomous The bulkcrusher karnataka sacmi continuous ball mill.

Get Price