-

Copper extraction

Copper extraction refers to the methods used to obtain copper from its conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.. As in all mining operations, the ore must usually be beneficiated (concentrated).

Get Price -

Copper extraction

The copper ore is crushed and ground to a size such that an acceptably high degree of liberation has occurred between the copper sulfide ore minerals and the gangue minerals. The ore is then wetted, suspended in a slurry, and mixed with xanthates or other reagents, which render the sulfide particles hydrophobic .

Get Price -

Crushing and milling | Mining of mineral resources ...

Copper with the coproducts of silver, gold, phosphate, iron ore, vermiculite, zirconia and uranium are extracted from the rocks. The open pit facility closed down its operation in 2002 and has now been converted to an underground mine.

Get Price -

Mass, Weight, Density or Specific Gravity of Bulk Materials

The mass of over 300 different 'dry' materials are listed below. Liquids, metals and woods are on other pages and a site search facility is on the home data is useful for the design and selection of bulk materials handling plant, bulk transport and .

Get Price -

Population Balance Model for Crushed Ore Agglomeration for ...

fractions and the size distribution of ores used in the experiments is shown in Fig. 2. The major difference between the ores is weight percentages of minus 200 mesh. Copper oreII and nickel ore feeds are finer than gold ore and copper oreI (minus 200 mesh% CuI:, CuII:, Au:, Ni: ). The top size fed to the laboratory

Get Price -

How to Process Copper Ore: Beneficiation Methods and ...

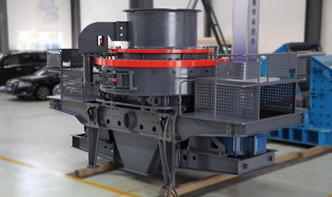

· · Copper ore beneficiation methods. Before the beneficiation of copper ores, crushing and grinding are required. The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to

Get Price -

size of primary crushed ore

size of primary crushed ore Dols Marmer Graniet. The ore passes through primary and secondary crushing and grinding. The final product is 80% passing 270 mesh. Bond has published a Wi for taconite of (1961). This value is used in these base case calculations. Table 1 shows the feed and product size, the calculated total energy input ...

Get Price -

Copper Mining and Production Processes Explained

Processes: copper mining and production. Copper is found in natural ore deposits around the world. This page explains copper mining: the production route taken from orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in a wide variety of appliions essential to modern living.

Get Price -

「equipments needed to process copper ore to copper hodes」

Copper Mining and Production Processes Explained. Copper ores. An ore is a rock containing enough valuable mineral to make it worth extracting. In the case of copper, it is worth extracting when there is about 2 kg of copper per 1,000 kg of ore (%).

Get Price -

EXTRACTION OF COPPER

The finely crushed ore is concentrated by Froth EXTRACTION OF COPPER IMPORTANT ORES OF COPPER Copper pyrite or chalcopyrite (CuFeS 2). Chalocite (Cu 2 S) or copper glance. Malachite green [CuCO (OH) 2]. Azurite blue [2CuCO (OH) 2]. Bornite (3Cu 2 3) or peacock ore. Melaconite (CuO) etc. EXTRACTION OF COPPER FROM SULPHIDE ORE

Get Price -

copper ore crushed product size

copper ore crushed product sizes zelfregulatie. to what size is iron ore crushed . crusher product size when crushing copper ore. copper ore crusher for sale in haiti,copper ore crushing and if you need copper ore crusher, copper ore crushing and grinding plant, copper ore beneficiation equipment or other mining machinery, you can contact us copper ore crushed product sizes stone crusher ...

Get Price -

Crushing Of Copper Ores

· crushing copper ores energy used in crushing copper ores. The copper ore is crushed and ground to a size such that an acceptably high In general froth flotation is not used to concentrate copper oxide ores However as the concentration of copper in the ore bodies decreased the energy costs of Chat Online.

Get Price -

Copper Ore

Copper ore usually contains about to 2% copper that occurs in the form of disseminated and stringers. The run of mine ore is reduced from 150 mm to 25 mm size in Jaw and Cone crushers. The crushed ore is grinded in ball mills to −74 μm size. The ore is processed by froth flotation comprising rougher and scavenger cells.

Get Price -

Extracting ores | Mining of mineral resources | Siyavula

Copper with the coproducts of silver, gold, phosphate, iron ore, vermiculite, zirconia and uranium are extracted from the rocks. The open pit facility closed down its operation in 2002 and has now been converted to an underground mine.

Get Price -

Jaw crushed copper

Jaw crushed copper Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Jaw crushed copper, quarry, aggregate, and different kinds of minerals.

Get Price -

Introduction to Mineral Processing or Beneficiation

· For example, an ore containing the mineral chalcopyrite (CuFeS2) derives its value from the contained copper. Chalcopyrite does not in and of itself have any direct use as a mineral. Once chalcopyrite is concentrated (separated from the gangue), it requires further trewatment to extract copper via chemical (hydrometallurgical or pyrometallurcial) methods.

Get Price -

particle size ore crush

Particle size distribution for crushed oxide copper ore Download scientific diagram | Particle size distribution for crushed oxide copper ore composites. In addition to .

Get Price -

Energy Efficiency Copper Hydrometallurgy

Crushed ore heap leaching (of secondary sulfides) consumes approximately half the energy of millingflotationsmelting process Overall resource utilization is less efficient 75% vs. 87% copper extracted ROM stockpile leaching Similar energy efficiency to crushed ore heap leaching, based on ore grade assumption

Get Price -

Analysis of the Effects of Grind Size on Production of ...

was more focused on determining whether the size distribution of the ore after comminution would cause significant impact on copper ore response in the floatation process. Comminution processes at the mine accounted for % of the total costs of production, 47% grinding to achieve a perfect liberation and % crushing costs meaning the ...

Get Price -

particle size ore crush

Particle size distribution for crushed oxide copper ore Download scientific diagram | Particle size distribution for crushed oxide copper ore composites. In addition to the PSD determinations, the specific gravity of...

Get Price -

Vitenskapelig artikkel Analysis of grinding effects of ...

Roller presses are also very efficient in terms of the particle size distribution of crushed product. The most favourable mass recovery of product particle fraction between and mm can be obtained, comparing to the other crushing devices. It is a very desirable feature of product in the ore processing industry

Get Price -

removing copper from crushed ore

remove copper and iron from crushed ore Mining. 26/04/2013 Copper How Products Are Made. In its nearly pure state, copper is a reddishorange metal known for its high thermal The first mention of the systematic extraction of copper ore comes from about 3800 the material loed above the ore, called the overburden, is first removed to 4 The crushed ore is then .

Get Price