-

Vale to build New Steel plant and boost dry iron ore ...

Feb 07, 2020 · Vale to build New Steel plant and boost dry iron ore processing aims. Vale says it plans to invest up to 100 million to build an industrial plant for dry magnetic concentration of lowgrade iron ore, bolstering its efforts to eradie wet tailings facilities at its mines. The technology, known as FDMS (fines dry magnetic separation), is ...

Get Price -

what is an iron ore wet plant

In many cases, ore with a total iron content of 60% to 63%, or greater, is regarded as high grade, and ore with a lower iron content is regarded as low ore wet processing plantIron ore wet processing plants, CDE Asia. Our iron ore processing plants target these contaminants and ensure their effective removal from the feed to the kilns.

Get Price -

News ResourcesMineral Processing Plant

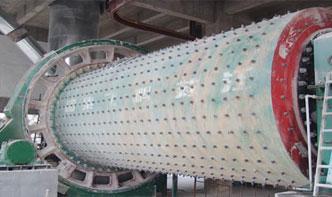

Jun 29, 2021 · Iron Ore Crushing and Screening Process. Mining and processing of iron ore involves crushing and screening. Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening. ... What is wet grinding. The main equipment of wet grinding is a wet ball mill. The structure of the wet ball mill is simple ...

Get Price -

iron ore processing plants in laos

Iron Ore Processing Plants In Laos. iron ore processing plants in us,iron ore processing plants iron ore wash plants cde. iron ore. efficiently remove silica and alumina contamination to increase efficiencies in steel production. our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the fe value of ...

Get Price -

iron ore crusher types samac

wet screening of iron ore definition. iron ore wet plant setup – SAMAC Processing Iron Ore – Tenova. Our iron ore processing plants are custom built to client requirements. modules and WHIMS ( Wet HighIntensity Magnetic Separation) modules for maximum of iron ore, as well as20 tph stone crusher plant cost in india. crushing and screening tower. mini portable gold wash plant in ...

Get Price -

CATALOGO CHROMITE PDF

Jun 24, 2019 · Chrome Separator Plant Chrome Machine jig separating solution for chromite sand separation. Alibaba offers 4, chromite for sale products. washing process of chromite ore beneficiation. Mineral processing equipment wet high intensity magnetic separator for sale chinese.

Get Price -

Iron Mining Process

At the processing plant, the taconite is crushed into very small pieces by rock crushing machines. The crushers keep crushing the rock until it is the size of a marble. The rock is mixed with water and ground in rotating mills until it is as fine as powder. Separation The iron ore is .

Get Price -

Tonkolili Iron Ore Mine, Sierra Leone, West Africa ...

Extracted ore was processed at a wet processing plant, which is supplemented by a mobile crushing, washing and screening plant and a semimobile crushing plant. Direct shipping iron ore was loaded into the rail cars using front end loaders and transported to the Pepel port where bottom dump trains are used to discharge iron ore onto the 3,000 ...

Get Price -

Outotec's sustainable screening technology to iron ...

Sep 17, 2021 · The need to reduce water in iron ore production and other minerals processing is a critical global challenge. The innovative and patented BSE Series screens enable iron ore processing even with higher natural moisture content without adding water.

Get Price -

(PDF) Feasibility Study of Iron Concentrate Production in WTP .

Feasibility Study of Iron Concentrate Production in WTP Circuit from New and Old Wet Tailings of GolEGohar Iron Ore Processing Plant. ... 14% and 27%, 22% respectively. Wet tailings processing ...

Get Price -

Iron Ore Wet Processing Plant In Australia

Iron Ore Wet Processing Plant In Australia. May 26 2016nbsp018332In doing this the company can produce a highly pure iron ore concentrate in an industrial scale by obtaining a premium product of up to 68 per cent iron as well as being able to make use of. Jaw Crusher.

Get Price -

Dust suppression in iron ore processing plants | SpringerLink

Nov 01, 2005 · To effectively suppress dust, the material must wet well and must remain wet. Surfactants, hygroscopic materials and binders are additives that address at least one of these concerns. Evaluating the wetting behavior of the iron ore revealed that the pellets were highly hydrophilic (contact angles less than 30°).

Get Price -

Mineral Processing Plants

We are indulged in providing specialized Iron Ore Processing Plant. Fabried from highest quality raw materials, these machines are provided with Feed Hopper, Ball Mill for grinding, Wash drum (Scrubber), Spiral Classifier bank, Hydrocyclones bank, Multideck Rectangle Vibratory Screens, Low; Medium high Intensity Magnetic Separators and Tailing Pond.

Get Price -

iron ore wetprocessing plant

Iron Ore Processing Plants Iron Ore Wash Plants CDEOur iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process. what is a wet processing plant iron ore SlideShareApr 11, 2015 · First 5 months of running the new ...

Get Price -

Industrial Mineral Processing Plant

Industrial Mineral Processing Plant. We are one of the leading manufacturer and exporter of Mineral Ore Beneficiation Plant Machines, fabried from superior quality of raw plants machines, specially designed for highest pressure performance, and are used in an assortment of of the features of these plants and machines are precision functionality, optimum ...

Get Price -

Tailings

Tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction of an are distinct from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.. The extraction of minerals from ore can be done two ways: placer mining, which uses water ...

Get Price -

iron processing | Britannica

iron processing, use of a smelting process to turn the ore into a form from which products can be in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth's crust, and it is the ...

Get Price -

iron mining processing plant

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin. 23/09/2019 Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation, flotation, etc., to improve the grade of TFe of the concentrate and get the best yield.

Get Price -

Iron Ore Wet Processing Plant In Afghanistan

Contrack Crush Plant Hilmond Afghanistan C and M Mining Machine randpic crush contrack crush plant hilmond afghanistan plants pakistan. iron ore mine primary crushing plant MORE INFO crushed stone processing in afghanistan semi wet process portland cement .

Get Price -

iron ore wet processing and crushing plant | Ore plant ...

Sep 12, 2013 · iron ore wet processing and crushing plant. Iron Ore Processing Plant|Mineral Beneficiation Machine|Gold . Gold Mining Equipment Gold Quarry Machine Manufacturer Products are exported to over 20 countries around the world,such as Malaysia, South Africa, Nigeria, .

Get Price -

240TPH Iron Ore Processing Plant in Pakistan

Sep 12, 2020 · 240TPH Iron Ore Processing Plant in Pakistan. How processing plant configurated, what equipments were used and how much cost? Read more...

Get Price -

Iron Bridge Magnetite Project, Australia

The ore will be crushed and processed at the site for the production of magnetite, dry process rejects, and wet tailings. The processing plant will use dry crushing and grinding circuit. The plant will employ the KB 63130 type gyratory crushers, which will be the largest crushers in the country.

Get Price -

"Dust suppression in iron ore processing plants" by C. R ...

Jan 01, 2005 · To effectively suppress dust, the material must wet well and must remain wet. Surfactants, hygroscopic materials and binders are additives that address at least one of these concerns. Evaluating the wetting behavior of the iron ore revealed that the pellets were highly hydrophilic (contact angles less than 30°).

Get Price