-

Coal washing | Coal preparation | Coal washing plant pcocess

Apr 10, 2019 · Clean coal is an energy that can generally be used as fuel, the fine coal of bituminous coal is generally used for coking. The main reasons of washing coal are as bellow: 1. Improve coal quality and reduce emissions of coalfired pollutants. Coal washing can remove 50%80% of ash and 30%40% of total sulfur (or 60%~80% of inorganic sulfur) in coal.

Get Price -

Coal preparation plant process and equipment for coal ...

Mar 27, 2019 · Taking a coal washing plant in Indonesia as an example, the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons, and the power consumption, media consumption, fuel consumption, and water consumption are all reduced. At present, the whole plant ...

Get Price -

Modular plants – A different approach to coal processing ...

Jan 13, 2021 · It is simpler to install a modular coal handling and processing plant than to build a conventional plant because the modular plant is designed, constructed and drycommissioned offsite. After commissioning, the plant is broken into modules sized for road, rail and ocean freight.

Get Price -

Threestages SKT Jig in Coal Washing Plant Appliion

HOT Mining developed SKT12 model ThreeStages Jig Washer on the basis of existing twostages jig washer. The new Jig Washer can meet requirement of improving final coal concentrate quality and quantity, it can increase coal concentrate recovery by at least 2%.

Get Price -

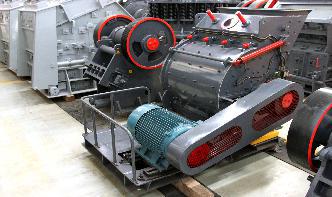

Wet coal crusher with a dry system

Wet coal crusher with a dry system Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Wet coal crusher with a dry system, quarry, aggregate, and different kinds of minerals.

Get Price -

Coal processing equipment | Schenck Process

Our coal processing solutions have proven themselves at the world's most demanding plants, freeing roughly 10 million tons of raw coal of impurities annually. Suitable for all advanced production techniques and built to handle numerous egories – including steam coal, coking coal, and anthracite – our heavyduty equipment can also be ...

Get Price -

Dry Coal Beneficiation | Empire Industrial Equipment

DRY COAL BENEFICIATION PLANTS. This is a Dry Mineral Processing technology, processing up to 200 tonnes per hour, without the need to add water, thereby proving its usefulness in dry or semiarid areas. Since construction is modular our system can be deployed to sites and assembled in a short timeframe. A low capital cost option for processing ...

Get Price -

dry beneficiation of coal review

Mar 22, 2016 · Dry beneficiation of coal ScienceDirect. Dry beneficiation is an alternative approach. The present work is a review and critical assessment of topics relevant to dry processing of coal, comprising comminution, size classifiion, characterisation and analysis, sorting at coarse sizes, mechanical beneficiation according to density at medium sizes ...

Get Price -

coal dry gravity separation

Dry Coal Processing Coal Washing Process. FGX dry coal processing is an effective deshaling technology developed by Tangshan Shenzhou Manufacturing Co Ltd TSM The FGX compound dry cleaning separator provides an efficient dry and gravity based separation by integrating two separation mechanisms including an autogenous fluidized bed and a .

Get Price -

Coal processing

Automation and control of a coal processing plant is a real challenge. A coal dredge. In order to automate, we first need to know the current operating position of the plant and how various changes affect operations – in particular, the dense medium cyclone (DMC) circuit, which processes 80 per cent of the plant's .

Get Price -

Method for processing fine coal

The large majority of current coal processing plants use a wet process to clean the coal. Ultrafine particles that enter into the wet processes cause inherent problems in subsequent handling of the fluids used in these wet processes. The fluid circuits in such processes become unwieldy and costly.

Get Price -

Coal Processing and Shipping Complex: Fluor Project in ...

At the Goonyella mine, Fluor designed and built a coal wash plant with associated coal handling, processing, stockpiling, reclaiming, and loading facilities; a 72mile pipeline between Eungella Dam and Goonyella to supply water for the coal washery, township, and other uses; four walking draglines, two with 60cubicyard capacity, and two with 45cubicyard capacity; and coal shipping port ...

Get Price -

4) COAL PREPARATION AND PROCESSING PLANT.—The term ...

Define 4) COAL PREPARATION AND PROCESSING PLANT.—The term. coal preparation and processing plant' means any facility (excluding underground mining operations) which prepares coal by one or more of the following processes: breaking, crushing, screening, wet or .

Get Price -

Flow Diagram For Coal Working In Crusher Plant Pdf

Flow Diagram For Coal Working In Crusher Plant Pdf. News Introduction:The scheme used in physical coal cleaning processes varies among coal cleaning plants but can generally be divided into four basic phases: initial preparation, fine coal processing, coarse coal processing, and final process flow diagram for a typical coal cleaning plant is presented in Figure

Get Price -

coal dry gravity separation

Dry Coal Processing Coal Washing Process. FGX dry coal processing is an effective deshaling technology developed by Tangshan Shenzhou Manufacturing Co Ltd TSM The FGX compound dry cleaning separator provides an efficient dry and gravity based separation by integrating two separation mechanisms including an autogenous fluidized bed and a conventional table separator

Get Price -

Coal Drying Methods

Feb 06, 2019 · The plant was producing a to 4% moisture product using the following drying procedures: The 6″ x ¼" was dewatered only on vibrating screens giving a moisture of %; the ¼" x 28 mesh product was dewatered in 110 centrifugal dryers giving a moisture of %; and the 28 mesh x 0 coal was dewatered by vacuum disc filtration with ...

Get Price -

Coal Preparation and Processing Plants New Source ...

Feb 24, 2021 · Those new performance standards were designed to further reduce emissions at new coal preparation and processing plants that process more than 200 tons of coal per day. Coal preparation and processing plants break, crush, screen, clean and/or use heat to dry coal at coal mines, power plants, cement plants, coke manufacturing facilities, and ...

Get Price -

How a Coke Plant Works

Oct 04, 2018 · How a Coke Plant Works. Coal is the main ingredient used to make coke. Iron is produced by inputting coal into a blast furnace. However, coal cannot be put directly into a blast furnace because of all the harmful byproducts that come from that. So, there is an intermediate process that occurs. Coal is converted into coke first.

Get Price