-

5 Best In Office Dental Milling Machines

Mar 02, 2021 · The Programill PM 7 is a strong contender in the best dental milling machine market. With both wet and dry milling capabilities, and an open software architecture, this machine can handle most (if not all) types of sameday solutions required for your dental office.

Get Price -

Pulverizer Capital Cost Of Dry Vs Wet Grinding | Crusher ...

Capital cost of dry vs wet grinding – Stone Crushers. Dry vs Wet grinding Generally speaking, dry grinding has lower capital costs than wet milling but does not have as high product value. There has been a well .

Get Price -

Wet Milling vs Dry Milling: The Differences, Advantages ...

Jun 17, 2021 · Wet Milling vs Dry Milling: The Differences, Advantages, and Challenges. Industrial milling is one of the most commonly used techniques in the manufacturing industry and can be divided into two egories: wet milling and dry milling. To understand the difference between the two, and the challenges that come along the milling process, we first ...

Get Price -

Dry and wet milling of corn

Feb 06, 2014 · Dry and wet milling of corn 1. DRY AND WET MILLING OF CORN NEHA RANA CCS HAU, HISAR 2. STRUCTURE AND COMPOSITION The mature corn is composed of four major parts: Endosperm 82% Germ 12% Pericarp 5% Tip cap 1% C o m p o n e n t s o f Yellow Dent Corn Starch % Corn Oil % Protein % Fiber % Moisture %

Get Price -

Wet vs dry milling 4130 or 4340? cutter coating?

Feb 08, 2008 · Wet vs dry milling 4130 or 4340? cutter coating? We typically cut Al. Have heard a bunch that dry milling is actually better than wet for some reason. Wondering what the consensus would be on this? Also curious what, if any, coating would be preferred for this type of steel work? Cutter sizes will not exceed 3/8 and material thickness will be 5/8

Get Price -

The Differences between Dry Milling and Wet Milling

Wet milling is milling using cutting fluid. Although dry milling can extend the tool life, the cost of cutting fluid treatment, health and safety issues are attracting more and more attention. The use of dry processing is a very valuable saving in technology, but in some cases, only .

Get Price -

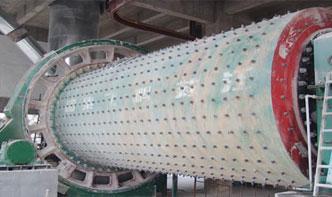

Wet Ball Milling Vs Dry Ball Milling | Orbis Machinery, LLC.

Jun 27, 2019 · The advantages Wet ball milling has over dry milling are higher energy efficiency, lower magnitude of excess enthalpy, better heat dissipation and absence of dust formation because of the aqueous environment it is being performed. Particle Size Reduction Milling the powder in the wet or dry state produces different results.

Get Price -

Wet vs. Dry/Air blast Machining

Feb 20, 2014 · Wet vs. Dry/Air blast Machining Here is the info of what I'm doing. Have parts that are machined from M2 tool steel, using Gibbs Cam with Volumill (hsm) for the roughing of the parts, 1/2'' helical end mill HEVR 5F.

Get Price -

Wet and Dry Milling Equipment

Oct 24, 2018 · Wet Milling. For a faster and more consistent drying process downstream, manufacturers may want to reduce the particle size of material. This increases the surface area of the product, enabling it to dry quicker before downstream processes. Through wet milling, lumpy and uneven powder can be reduced to a uniform particle size.

Get Price -

Nanosized crystalline drug production by milling ...

Wet milling using a highpressure homogenizer is another alternative to preparing productionscale drug nanosuspensions. Dry milling is a simple method of preparing a solidstate drug nanoformulation. The effect of size on the dissolution of a drug from nanoparticles is an area of fundamental research, but it is sometimes incorrectly evaluated

Get Price -

milling green or dry wood? | Homesteading Forum

Feb 18, 2013 · Mill it fresh/wet/green. Know what you would like to make from the lumber and pick each log for that type of lumber. That doesn't allways apply but if it does keep it in mind. ... it gets tough when halfway between wet and dry ( so even if sawing low grade for blocking it needs to be sawed wet.) As far as advice for drying. I agree with ...

Get Price -

Milling ByProducts of Cereal Grains

Wet milling of corn is a more extensive process than dry milling. Figure illustrates an overview of the wet corn milling process. In brief, wet milling involves cleaning, steeping, grinding, extraction, other separation processes, and drying of the products.

Get Price -

Dry and Wet Milling » VOGELBUSCH Biocommodities

Dry and Wet Milling Two different approaches in grain processing. As only the starch is needed as a carbohydrate source for the biological conversion process, the remaining ingredients of a raw material such as proteins, minerals, fat and fiber, in turn can provide valuable products.

Get Price -

Physicochemical properties of ball milled boron particles ...

The advantage of using wet ball milling process compared to dry milling process is that it is possible to make a more uniform coating on the surface of particles by decomposing the precursor ...

Get Price -

The Quest for Nanotechnology and the Evolution of Wet and ...

Mar 30, 2017 · Drymilled materials have the tendency to agglomerate after processing, or when later added to liquid, will also tend to agglomerate. This can be avoided when initially mixed with the liquid carrier and processed in a wet media mill. Wet milling encapsulates the dry particle, surrounding it with liquid and preventing reagglomeration.

Get Price -

Difference between dry and wet maize milling process

Difference between dry and wet maize milling process Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Difference between dry and wet maize milling process, quarry, aggregate, and different kinds of minerals.

Get Price -

Impact milling of pharmaceutical agglomerates in the wet ...

Jun 04, 2021 · For example, in the pharmaceutical industry, milling is used at various manufacturing stages, including wet and/or dry milling after crystallization of drugs to reduce the particle size or achieve ...

Get Price -

When to Use Wet Milling or Dry Milling?

Nov 24, 2020 · dry milling. Dry milling can prolong the life of cutting edge. The temperature does change, but it will remain within the design range of cemented carbide materials. Rough milling should always be carried out without cutting fluid. wet milling with cutting fluid. There are some exceptions to the use of cutting fluid:

Get Price -

wet milling vs dry milling

Corn Milling: Wet vs Dry Milling AMG Engineering. Corn wet milling and dry milling are the predominant methods of processing and each method produces distinct coproducts The Corn WetMilling Process The Corn wetmilling process is designed to extract the highest use and value from each component of the corn kernel The process begins with the corn kernels being .

Get Price -

Where Dry Milling Makes Sense | Modern Machine Shop

Oct 15, 2000 · That was the case with this Stavax 420 stainless steel mold core. When dry milling wasn't producing an acceptable surface finish, the operator switched to using liquid coolant and the finish improved. Two finishmachined bands in the forward area of the part show the difference. The lower band in the inset photo is the area machined dry.

Get Price -

wet milling vs dry milling

Wet Grinding VS Dry Ball Mill Grinding. Jul 03 2017 Wet and Dry Open Circuit Ball Milling Continuous grinding will have a more prominent place in the remaining part of this paper Dry grinding has been introduced already and more will be said about it The results shown in table 18 are from continuous open circuit work done to compare wet and dry grinding First it must be said that by choice

Get Price -

Ideal solutions for wet and dry milling | British Dental ...

Feb 24, 2017 · With over 30 years' experience in manufacturing desktop milling technology, Roland DG has developed the ideal solutions for wet and dry milling, to deliver maximum productivity and avoid ...

Get Price -

wet grinding milling

Wet Grinding VS Dry Ball Mill Grinding. Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages The results are summarized in table 16 which shows that in both capacity and efficiency grinding was .

Get Price -

Wet milling

Wet milling Wet milling with IKA's inline machines is a safe and efficient alternative to dry grinding. Dry grinding creates a lot of dust which causes the need for proper filtering systems. This can be of particular importance during grinding of substances whose dust, when mixed with aerial oxygen, can result in explosive mixtures.

Get Price