-

ARBG Copper Cathode

Copper hode from the smelter is melted and cast as anodes, the solution from the solvent extraction process moves to a plating operation. 5: Sulfide Ore Refining The final step in processing sulfide ore copper from the smelter is to make high purity copper hodes.

Get Price -

Copper Copper Ore Purifiion EXODUS Mining machine

How Hydrometallurgy And The Sxew Process Made Copper. The sxew process has provided the copper industry with a tool that makes the extraction of copper from its ores significantly more environmentally friendly than by the use of the conventional smelting process while the sxew process was adopted by the industry to take benefit from the sulfuric acid that the smelting process produced .

Get Price -

coopper ore processing from minning to fuel purifiion

Copper Ore Processing From Mining To Purifiion Sudan. Feb 28, 2020· Copper ore processing from mining to purifiion. Coopper ore processing from minning to fuel . copper processing interactive oresome resources this is an interactive activity that allows students to explore the processes involved in the mining and processing of copper ore and the production of copper .

Get Price -

Electro Copper Refining

An example where copper is further purified is at the Asarco electrolytic plant in Amarillo, Texas. The 99% pure copper from the anode furnace is cast into 750pound, 3inch thick, rectangular slabs called anodes. The final step is a process called electrorefining.

Get Price -

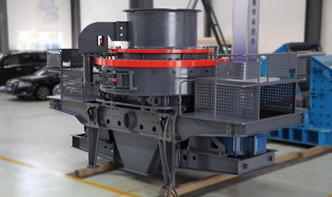

Copper Ore Processing Plant Flow Chart Ls

Copper Mining Equipment Copper Processing Plant Flow Chart. Copper Processing Plant Com. Copper Process Flowsheet Example A simplified schematic drawing of copper flotation flowsheet runofmine open pit ore will be crushed in a gyratory crusher the crushed ore will be processed by means of semiautogenous and ball mill grinding followed by rougher flotation .

Get Price -

copper mining_processing_lecture_final

May 03, 2018 · The copper ores undergo different processing depending on their chemistries Oxide Ore: Hydrometallurgy Heap Leaching Solvent Extraction Electrowinning Mining Transporting Primary Crushing Sulfide Ore: Pyrometallurgy Froth Floatation Thickening Smelting Electrolysis Final Product: % pure copper hode 12.

Get Price -

Copper Mining and Extraction: Oxide Ores (1416 ...

Most of the copper ores mined today are oxide or sulfide ores. Extraction of sulfide ores is covered in more detail in Copper Mining and Extraction: Sulfide Ores (11–14), but is introduced here because an important byproduct of this process is used for the extraction of oxide ores. Pyroprocessing Sulfide Ores Provides Acid for Leaching

Get Price -

Mineral processing | Solvay

Mineral processing. Solvay's reagent portfolio includes offerings designed for the recovery of precious and base metals, such as copper, molybdenum, gold, nickel, cobalt, platinum group metals and polymetallics. We also offer products for various industrial minerals such as phosphate. Mining operations worldwide turn to Solvay to address ...

Get Price -

(PDF) Life cycle assessment of copper and nickel production

Lower mined ore grades mean that more ore needs to be processed to produce the same amount of metal, leading to a rise in energy requirements and thus GHG emissions (Norgate Haque, 2010; Norgate ...

Get Price -

Mining and enrichment | KGHM Corporate Website

Copper and silver are indispensable natural resources for the development of global economy. During 60 years of company's activity, KGHM has extracted over a billion tonne of mining output and has produced 20 million tonnes of copper. Current deposits will suffice for the next 4050 years of mining activities. The copper ore deposit operated by KGHM in Poland dips .

Get Price -

inorganic chemistry

Aug 26, 2021 · Most of the sulfur in the chalcopyrite turns to sulfur dioxide gas. This is used to make sulfuric acid via the contact process (copper extraction and purifiion). Overall equations for these series of steps are: (1) 2 C u F e S X 2 + 2 S i O X 2 + 4 O X 2 C u X 2 S + 2 F e S i O X 3 + 3 S O X 2. (2) 2 C u F e S X 2 + 3 O X 2 2 C u S + 2 F e O ...

Get Price -

Copper Mineral, Extraction of Zinc, Extraction of Copper ...

Final copper concentrate contains copper % and lead %, and the lead concentrate contains lead % and copper %. A copper lead zinc ore dressing plant in Inner Mongolia, the mainly components of the ore are copper, lead, zinc, and a certain amount of magnetite. According to ore properties and a series of processing tests, Xinhai ...

Get Price -

Heap leaching

Heap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from ore using a series of chemical reactions that absorb specific minerals and reseparate them after their division from other earth materials. Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to the ...

Get Price -

copper ore processing plant

Copper processing is a complied process that begins with mining of the ore (less than 1% copper) and ends with sheets of % pure copper called hodes, which will ultimately be made into products for everyday most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and ...

Get Price -

Sustainability Analysis of Copper Extraction and ...

Jan 01, 2014 · Although life cycle of mining and mineral processing systems, including copper production, have been carried out since the mid to late 1990s; these studies are limited to the ore extraction and mineral processing, not considering waste management, which is the most important part of metal production systems when assessing their environmental performance.

Get Price -

ore processing in copper mining | Prominer Mining Technology

Copper mining and the copper extraction process . If you are thinking of investing in copper, this article explains copper mining and the copper extraction process: how copper is extracted from the earth's ores. It also summarises where the main copper mining regions are lo ed and identifies who the major producers are. Copper mining.

Get Price -

In situ recovery of copper sulfide ores: Alternative ...

Sep 01, 2020 · In process scheme 2, insitu mining (ISM), the ore bed porosity was sufficient for air to circulate and keep an adequate supply of oxygen and carbon dioxide across the whole ore bed column. This is a situation reached in heap bioleaching when air is blown through the base at flows over 6 L/min m 2 ( Lizama, 2001 ).

Get Price -

Copper Production: How Is Copper Made?

Sep 26, 2019 · Copper processing is a complex process that involves many steps as the manufacturer processes the ore from its raw, mined state into a purified form for use in many industries. Copper is typically extracted from oxide and sulfide ores that contain between and % copper.

Get Price -

copper ore processing from mining

Copper Mining and Extraction Oxide Ores. Most of the copper ores mined today are oxide or sulfide ores Extraction of sulfide ores is covered in more detail in Copper Mining and Extraction Sulfide Ores 11–14 but is introduced here because an important by product of this process is used for the extraction of oxide ores Pyroprocessing Sulfide Ores Provides Acid .

Get Price -

process of copper ore purifiion

purifing process for ores Ore processing. It does not process (as of 26130ex110) ores for coal, lapis, diamond, redstone, emerald, or nether quartz Crushed ore can be smelted into ingots (except for uranium) Stage 2 An Ore Washing Plant processes crushed ore into purified crushed ore (using 1000 of water in addition to EU), with tiny ore dust and Stone Dust as byproducts.

Get Price -

copper ore processing from mining

Copper Mining and Extraction Oxide Ores. Most of the copper ores mined today are oxide or sulfide ores Extraction of sulfide ores is covered in more detail in Copper Mining and Extraction Sulfide Ores 11–14 but is introduced here because an important by product of this process is used for the extraction of oxide ores Pyroprocessing Sulfide Ores Provides Acid for Leaching

Get Price -

solvent extraction copper process pdf

May 11, 2013 · The CESL Copper Process consists of four main steps: copper mineral .. Impurities are removed from the copper rich solution by solvent extraction, a conventional process used throughout the world. .. View CESL Copper Process PDF .. EXTRACTION OF COPPER AT ELEVATED FEED .. – SGS.

Get Price -

Copper Flotation

May 16, 2016 · A Copper Flotation Flowsheet. Because the copper in this type of ore usually assays only plus or minus 1% copper, the porphyry copper operations must be relatively large in order to be commercial. The flowsheet in this study illustrates a typical 3,000 ton per day operation. In general most operations of this type have two or more parallel ...

Get Price