-

Failure analysis of coal mill using FMEA in thermal power ...

Download Citation | Failure analysis of coal mill using FMEA in thermal power plant | Failure Modeand Effects Analysis (FMEA) technique is used to identify potential failure modes for a product or ...

Get Price -

Coal bunker / coal mill | S. r. Thermonix Technologies

Pulverized coal is typically used to fire the boiler of power plants. Due to safety reasons, monitoring of CO in coal bunkers and coal mills is an essential issue. CO is an odourless and very toxic gas and imposes a serious explosion thread at levels above 8 vol.% in air. Enhanced CO concentrations may indie a seat of smouldering and require ...

Get Price -

coal mill coal processing plant

coal Mill,coal processing plant,coal pulverizer. The system of blast furnace pulverized coal has been widely used in electric power, steel and metallurgical industry. In the whole system, the preparation of pulverized coal is the most important step.

Get Price -

Coal Mining Process Flowchart

Firstly, large coalbearing stones are crushed by coal crushers to a size of 20 to 25 mm, and then they are fed to coal bunkers. Through the vibrating screen, those crushed coal stones are continuously enter the coal mill. Coal gets ground by grinding machines in the coal plant. Coal particles get recirculated around four times before ...

Get Price -

power plant coal mill process

For example, a pulverizer mill is used to pulverize coal for coustion in the steamgenerating furnaces of fossil fuel power plants. > Learn More. coal mill model in thermal power plant g4h Coal mill primary air flow soft sensor model was established based on least a good appliion prospect in the detection process of a thermal power plant.

Get Price -

The firing and cofiring of biomass in large pulverised ...

• The coal mill depends on a crushing mechanism, and tends only to break the pellets back ... • Heat and power plant successfully converted from coal firing to biomass firing in 1993, and is still in operation ... which involves the conversion of roller mills to processing wood pellets.

Get Price -

Coal Preparation Plant | Coal Preparation Process | Coal ...

[Coal Washing]: As coal preparation plant is divided into dry preparation and wet preparation, the processes of coal preparation with jig and heavy medium cyclones generally need to use water as the separaton medium, so it is also known as a coal washing the coal processing with air separation, screen separation or manual separation, etc. that without use .

Get Price -

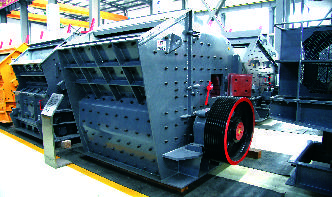

Mining Equipment: Coal Mill

20/09/2010 · The coal is processed and crushed to increase the efficiency and protect environment. In order to use coal more rationally, efficiently and effectively, the coal need to be processed and crushed into different sizes, 0 ~ 25 mm particle size for coal gas stove, 25 ~ 8 mm for steam locomotive, 25 ~ 6 mm for the industrial furnace, and coal power plant requires grain coal of 0 ~ 25mm.

Get Price -

FAULT DETECTION IN COAL MILLS USED IN POWER PLANTS ...

01/01/2006 · 2. THE COAL MILL The work presented in this paper, is based on a Babcock MPS 212 coal mill used at Elsam's Nordjyllandsværktet Unit 3. However, the method proposed in the paper is so generic that it can be applied to other types of coal mills. The coal mill is .

Get Price -

FAULT DETECTION IN COAL MILLS USED IN POWER PLANTS ...

01/01/2006 · 2. THE COAL MILL The work presented in this paper, is based on a Babcock MPS 212 coal mill used at Elsam's Nordjyllandsværktet Unit 3. However, the method proposed in the paper is so generic that it can be applied to other types of coal mills. The coal mill is illustrated in principles in Fig. 1.

Get Price -

Coal Mill – Coal Mill In Cement Plant | AGICO Cement Equipment

The coal mill grinding system is an important part of the dry process cement manufacturing. In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination. However, due to the flammable and explosive .

Get Price -

COAL BASED THERMAL POWER PLANTS: COAL MILLS FOR .

13/12/2011 · Pulverized coal is the most efficient way of using coal in a steam generator. The coal is ground so that about 70 % will pass through 200 mesh ( mm) and 99 % will pass through 50 mesh ( mm). A pulverized coal boiler can be easily adapted for other fuels like gas if required later without much difficulty.

Get Price -

Coal Processing Plant Photos and Premium High Res Pictures ...

469 Coal Processing Plant Premium High Res Photos. Browse 469 coal processing plant stock photos and images available or start a new search to explore more stock photos and images. industrial rafinery coal processing plant stock pictures, royaltyfree photos images. Chimneys and refinery equipment processing coal and mineral on the harbor.

Get Price -

ABC OF THERMAL POWER PLANT: MILLS IN A THERMAL POWER ...

09/06/2013 · Coal from travelling belt of raw coal feeder drops in central feed pipe ( connection between Raw Coal Feeder and Mill). After coal reaches Mill bowl grinding started and hot air also been given to make the pulverised fuel dried enough to classifier chamber. The portion of the coal which cannot be grinded finds its way to mill reject.

Get Price -

ABB MEASUREMENT ANALYTICS APPLICATION Safety .

2 Safety measurements of coal bunkers and mills for power plants and cement plants | AN/ANALYTICAL/202EN Rev. A — Safety measurements of coal bunkers and mills for power plants and cement plants — 01 Schematics of the flue gas line in a power plant Motivation Fires and explosions in these facilities are of increasing concern.

Get Price -

COAL BASED THERMAL POWER PLANTS: COAL MILLS FOR .

13/12/2011 · Pulverized coal is the most efficient way of using coal in a steam generator. The coal is ground so that about 70 % will pass through 200 mesh ( mm) and 99 % will pass through 50 mesh ( mm). A pulverized coal boiler can be easily adapted for other fuels like gas if .

Get Price -

Coal Mill and Coal Milling Plant

The coal flow into the boiler is an crucial element for a coal fired power plant. But in fact, it is not effortless to measure the coal flow from the coal mill to the furnace. The coal flow out of the coal mill is usually estimated based on the incoming coal flow. Coal milling plant for coal mining

Get Price -

EnergyTech 201 Coal Mill CO Analyser

The most reliable and accurate method of detecting coal fires or smouldering is to monitor the carbon monoxide levels within the coal handling plant areas such as silos and mills and to detect rapid increases in concentration. The CODELEnergyTech 201 samples the gas from the critical area through a steel sintered filter mounted in the wall of ...

Get Price -

Coal Preparation Plant | Coal Preparation Process | Coal ...

[Coal Washing]: As coal preparation plant is divided into dry preparation and wet preparation, the processes of coal preparation with jig and heavy medium cyclones generally need to use water as the separaton medium, so it is also known as a coal washing the coal processing with air separation, screen separation or manual separation, etc. that without use of water is called a coal ...

Get Price -

Coal mill feed belt – monitoring band loading | VEGA

To fuel the power plant boilers, chain conveyors must first bring raw coal from the bunkers. Feed belts (distributors) then transport the coal to the coal mill, where it is ground into dust and blown into the boiler. In order to ensure the fuel supply to the boiler in periods of full load, and especially low load, three redundant measuring ...

Get Price -

Coal Mills for Cement Plants | Loesche

Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations. Special versions are available with characteristics that meet special safety regulation or output control requirements.

Get Price -

Coal Mill Coal Processing Plant

What Is A Coal Mill In Coal Processing Plant. What Is A Coal Mill In Coal Processing Plant Coal washing plant Coal washing is the process of removal of the contaminants and the lower grade coal to achieve a product quality which is suitable to the appliion of the end user either as an energy source or. View Details Send Enquiry

Get Price