-

Magnetic separation

Magnetic separation is the process of separating components of mixtures by ... The first pair of balls was weakly magnetized and served to draw off any iron ore present. The second pair were strongly magnetized and attracted the wolframite, which is weakly magnetic. These machines were capable of treating 10 tons of ore a day. Common appliions. Magnetic separation .

Get Price -

Recovery of titanium from beach sand by physical separation

In this separator magnetic field strengths up to tesla were attainable in the gap between disc and flat pole stationary magnets placed below the disc. Representative beach sand samples were used for this test work. Samples were fed through a vibrating feeder. Magnetic minerals were picked up and transported by the revolving disc and deposited as a magnetic fraction, whereas non magnetic ...

Get Price -

CHAPTER8 BENEFICIATION OF IRON ORES

MAGNETIC SEPARATION PRINCIPLES AND APPLICATION IN BENEFICIATION OF IRON ORES A. Das and S. Roy INTRODUCTION Magnetic Separation is one of the physical concentration processes that utilizes the differences in magnetic properties of various minerals present in the ore body. The magnetic fraction may be valuable or gangue depending upon .

Get Price -

Developments in the physical separation of iron ore ...

· While magnetite is naturally suitable for magnetic separation, oxidized iron ores are much more difficult to recover using magnetic separators, because their magnetic susceptibilities are only about 1% of that for magnetite. Of the oxidized iron ores, specularite is most susceptible to magnetic fields, as it is better crystallized, followed by martite and .

Get Price -

Iron ore

Iron ore The SGM XRay transmission sorter is the ideal solution for preconcentrating iron and manganese ores by means of a dry process. The new proprietary SGM MIMS (Medium Intensity Magnetic Separator) wet drum magnet constitutes a true innovation to fill the gap between the traditional LIMS (Low Intensity Magnetic Separator) and WHIMS (Wet High Intensity Magnetic Separator).

Get Price -

Magnetic Separation Of Iron Ore

dry iron ore magnetic separator sale . Aug 2 2016 Stone Crusher Machine for Sale second iron ore magnetic separation process Ernest Henry CTDG dry drum magnetic separator for lump iron ore live chat magnetic iron ore separators for sale vajirasriorg Dry Iron Ore Magnetic Separators Sale asdsin STEINERT are world leading manufacturers of mining coal Iron Ore and

Get Price -

Iron Recovery from Bauxite Residue Through Reductive ...

Keywords Bauxite residue Iron recovery Magnetic separation Roasting process Introduction Bauxite is an important ore that is widely used to produce metallurgicalgrade alumina (the precursor for aluminum production) and chemicalgrade alumina/aluminum hydroxide for many industrial appliions through the Bayer process [1]. During this process, a byproduct is .

Get Price -

Ore Separation Methods Of Iron

Iron ore after magnetic separation: (a) tailings; (b) ironore concentrate. Ezhov and Shvaljov / Procedia Chemistry 15 (2015) 160 – 166 4. Conclusion By means of the optical analysis it has been determined that ferruginous ore particles represent oolites – . Get Detail; Seperation Methods Of Iron Ore. · seperation methods of iron ore. seperation methods of iron ore ...

Get Price -

Separation of Mixtures using Sublimation and Magnets ...

· The dish is then carefully heated on a sand bath. The vapours that pass through the holes of the filter paper cool down and condense on the inner sides of the funnel. The nonvolatile impurities will remain as a residue in the china dish. Separation by a Magnet. The technique of separation by a magnet depends upon the process of separating components belonging to mixtures by the use of a ...

Get Price -

MAGNETIC SEPARATORS

Magnetic substances Separation in fl uid (wet) High magnetic force separator (dry) Aluminum separator Used for a coolant separator (removal of iron particles in grinding fl uid, waste oil, cooling oil), drum separator (collection of iron ores, iron sand materials) and MAGFIN (removal of iron particles deposited in oil tanks). Magnetic drum

Get Price -

Developments in the physical separation of iron ore ...

· · While magnetite is naturally suitable for magnetic separation, oxidized iron ores are much more difficult to recover using magnetic separators, because their magnetic susceptibilities are only about 1% of that for magnetite. Of the oxidized iron ores, specularite is most susceptible to magnetic fields, as it is better crystallized, followed by .

Get Price -

Magnetic Iron Ores Separation

Iron Ore Magnetic Separation Processing Plant Design Iron Ore Magnetic Separation Process As we know iron ore is the important raw material for iron Beneficiation of Iron Ores ispatguru . Learn More. What Is Iron Ore Beneficiation With Pictures. Aug 08 2020nbsp018332The end product that emerges from crushing and magnetic separation equipment is then ground into .

Get Price -

Magnetic separation for mining industry – Magnetense

This type of magnetic separation machine is used in wet separation processes for smaller than 1,2 mm ( – 200 mesh of 30100 %) of fine grained red mine (hematite) limonite, manganese ore, ilmenite and some kinds of weakly magnetic minerals like quartz, feldspar, nepheline ore and kaolin in order to remove impurity iron and to purify them.

Get Price -

Magnetic separation of Red Sand to produce value ...

This note documents investigations into processing Red Sand through standard mineralogical processes (Low Intensity Magnetic Separator – LIMS and Wet High Intensity Magnetic Separator – WHIMS), to produce various fractions that have a higher potential value than the total sand fraction. One product is high in iron oxides, typically about 40% as Fe. Another .

Get Price -

Magnetic Separation Of Iron Ore Sand

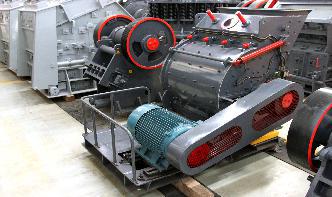

Magnetic Separation Of Iron Ore Sand. The fine ore can pass through the crushing mill mining machinery again and the matrix which mixing with the fine ore can be wiped out to upgrade the purity of fine ore the production line of sand magnetic separator energy mineral equipment sand magnetic separator for Jaw Crusher. Impact Crusher. Cone Crushers. Sand Maker. Ball Mill. Raymond Mill. Sand ...

Get Price -

When do we use magnetic separation method for ...

4. Leaching. Magnetic separation This is based on difference in magnetic properties of ore components . If either of the ore or the gangue (one of these two) is capable of being attracted by a magnetic field, then such separations are carried out. For example In case of iron ores like Magnetic (F e3. .

Get Price -

magnetic separation of iron sand

Upgrading iron ore fines (10micron to 1mm) Recovery of fine iron ore from tailing streams Separation of ilmenite from heavy mineral sand concentrates to reduce downstream processing Removal of magnetic contaminants from slurried materials eg cassiterite, kaolin, silica, etc . Get Price; How Do You Separate Sand, Salt and Iron Filings . How Do You Separate Sand, Salt and Iron .

Get Price -

How Does a Magnetic Separator Work | GTEK Magnet

Magnetic Separator can be applied in ore processing for separating magnetic materials, particular Iron. The advent of magnetic separation found favour in mineral processing for over 200 years ago. 2. Magnetic separators for product cleaning; Most common appliions are listed as below: Purifiion of Kaolin; Removal of magnetic minerals from high quality quartz sand; .

Get Price -

CHAPTER8 BENEFICIATION OF IRON ORES

MAGNETIC SEPARATION PRINCIPLES AND APPLICATION IN BENEFICIATION OF IRON ORES A. Das and S. Roy INTRODUCTION Magnetic Separation is one of the physical concentration processes that utilizes the differences in magnetic properties of various minerals present in the ore body. The magnetic fraction may be valuable or gangue depending upon its end use in a particular process and .

Get Price -

How to remove iron from silica sand by magnetic separator ...

· The wet magnetic separator is used to improve the magnetic contact area of silica sand and reduce the inclusion of iron impurities, so that the effect of iron removal is more obvious. For more information about quartz sand extracting and iron removal, please visit SINONINE website:,or contact us directly by + ...

Get Price -

Factors affecting the magnetic separation process ...

· Magnetic effect of many factors, impact crusher in India the magnetic separator is the following: 1) magnetic separator cylinder rotation; 2) magnetic system angle; 3) work space (ie, Park tube and the bottom of the gap); 4) Pai concentrate. — magnetic separators Our company specialized in producing all kinds of ore processing and mining equipment, including gold, all kinds of iron ore ...

Get Price -

How fines dry magnetic separation could solve mining's ...

· So how does fines dry magnetic separation actually work? At the heart of the new system are some incredibly powerful magnets. Made from rare earth metals, they can separate iron ore and other minerals far easier than ceramic alternatives. After crushing the ore, drying it and divvying particles by size, Vale's engineers let the super magnets ...

Get Price -

Dry ElectroMagnetic

ElectroMagnetic Dry separator. Device Concept. Objects that are attracted to a magnetic field have a property that is known as "ferromagnetic." For example, Magnetite, Iron, Nickel, and thier alloys are all ferromagnetic.

Get Price -

Magnetic separation of Red Sand to produce value ...

· · Magnetic separation of Red Dry drumTo determine if Darling Range Red Sand could be magnetically separated, a proof of concept trial was conducted using a Reading bench top magnetic separator. Analysis of the fractions ranging from to T indied that magnetic separation was possible but not as efficient as hoped. The non ...

Get Price