-

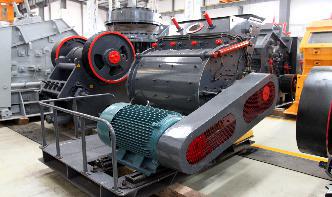

gyratory and cone crushers

Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not needed.

Get Price -

Cone Crusher Explained

Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the primary crusher. Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always).

Get Price -

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Cone Crushers. Originally designed and developed by (1920). Similar to gyratory except the spindle is supported at the bottom of the gyrating cone instead of being suspended. The head to depth ratio is larger than gyratory crushers. Cone angle are .

Get Price -

Tips to maximize crushing efficiency

· Cone and gyratory crusher considerations. Make sure the cone crusher does not get ring bounce or chatter. Variable flow controlled by level sensors will ensure consistent feeding and maintain a full crushing chamber. Low oil temperature should prevent operation of the unit. High oil temperature should stop the crusher feed and allow the unit to ...

Get Price -

PQ University Lesson 7 Crushing Secondary Breaking ...

· CONE CRUSHER. Cone crushers are similar to gyratory crushers in that they have a mantle that rotates within a bowl, but the chamber is not as steep. They are compression crushers that generally provide reduction ratios of 6to1 to 4to1. Cone crushers are used in secondary, tertiary and quaternary stages.

Get Price -

Difference Between Cone And Gyratory Crushers

Difference between cone gyratory crusher difference between cone and gyratory crushers gyratory cone crushers can be used for primary or secondary crushing and fine cone crusher are both gentle dip erect frustum cones and between crusher crushing cost fuction rate of get price what is the difference between a jaw crusher and a more.

Get Price -

Midsouth Machine Service

Midsouth Machine Service Company hosted a three day training course for cone crusher repair and rebuild, which was conducted by Machine in Pekin, Illinois. Excel is a manufacturer of premium high performance replacement parts for the mining and aggregate industries and a .

Get Price -

Cone Vs Gyratory Crushers

Cone Crusher Vs Gyratory 3f. Cone vs gyratory crusher mine equipmentshat is the cost difference between a gyratory crusher a jaw jaw crushers and gyratory crushers are used in the mining industry to break and crush rock materialform a conelike feeder into the crusher space, making the fed material smaller as it ttle of the veggies organic vs.

Get Price -

Crushers

Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not needed.

Get Price -

5 Types of Cone Crushers Comparison

· Gyratory cone crusher 【Appliion】 The gyratory cone crusher is suitable for the fourth stage of mediumhard materials crushing. Its special crushing cavity shape can do laminating crushing, obtain a small product granularity even in the large discharge size. Therefore, the rotary cone crusher is also often called the superfine crusher.

Get Price -

Gyratory Crusher : Principle, Construction, Working, and ...

· Gyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley, appliances and dry oil, thin oil lubriion system components etc.

Get Price -

Crusher Equipment Africa

CE Africa offers Gyratory, Jaw Cone Crushers Spares, Repairs refurbishment. We Strip, Assemble, Machine or Supply All Crusher Equipment info

Get Price -

Gyratory Crusher l Introduce, Working Principle

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher. The gyratory crushing equipment has a bright future in the mineral processing market. Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to form two optimal crushing cavities for the pliers.

Get Price -

gyratory and cone crusher differences

cone crusher vs gyratory crusher concertinacoilscoin. Gyratory Crusher Cone Crusher Mantle Differenc Any of you that are at all familiar with the Gyratory crushers and Cone Crushers that the former are used as Primary crushers will probably note,...

Get Price -

Gyratory Cone Crusher Manufacturer | Propel Industries

Crushers. GYRATORY CONE CRUSHER. The Gyratory Cone Crusher delivers increased capacity with reduced maintenance and downtime. It guarantees troublefree operation in varying feed conditions with a high reduction ratio. It has large and stable feed opening, steep cavity and effective strokes.

Get Price -

difference between gyratory and cone crusher

Gyratory cone crusher difference jaw crusher ball mill 511 cone crushers cone crushers are monly used for secondary tertiary and quaternary crushing duties two variations are available standard and short head the chief difference between cone and gyratory or jaw crushers is the nearly parallel arrangementgyratory cone crusher difference.

Get Price -

Gyratory Crusher Gape | Crusher Mills, Cone Crusher, Jaw ...

A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory Cone Crusher are designated in size either by the gape and .. Chapter 5. Gyratory and Cone Crusher – #2fishy on Scribd .. A conveyor belt fed a RunofMine iron ore to a gyratory crusher, which had a gape of 356 cm.

Get Price -

Simulation and advanced control of transient behaviour in ...

• Gyratory cone crushers are commonly used comminutionequipment in mines and quarries – Gyratory cone crusher in this work refers to the secondary and tertiary hydroconetype crushes • Disturbances like changes in feed material size hardness and wear of crushing liners cause variation in the crusher output

Get Price -

Gyratory Crusher

A gyratory crusher is an ore processing machine that crushes the ore between an eccentrically mounted cone and a crushing throat that is fixed. In mining, the most important criteria for effective crushing of oresis to choose the type of crusher that suits the rock (ore) material and to ensure uniform feed.

Get Price -

difference between cone and gyratory crushers

Gyratory cone crushers can be used for primary or secondary crushing. ... and fine cone crusher are both gentle dip erect frustum cones, and between... crusher; crushing cost, fuction, rate of cone crusher in india; difference. There Are Different Rock Crusher at Both Home and Abroad ...

Get Price -

Gyratory Crusher l Introduce, Working Principle

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher. The gyratory crushing equipment has a bright future in the mineral processing market. Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to form two optimal crushing .

Get Price