-

vibratory screen for coal cleaning plant

vibratory screen for coal cleaning plant . Inclined Vibrating Screen Coal Processing Star Trace. The various versions of these Vibro Screens permit its use for wet and dry screening, coarse and fine separations and are widely used in steel mills, mineral beneficiation plants, chemical, mining, food and fertilizer industries, coal preparation plants and many others. Coal Vibrating Screen. Coal ...

Get Price -

vibratory screen for coal cleaning plant

Vibratory Screen For Coal Cleaning Plant Crusher USA About vibratory screen for coal cleaning plantrelated information:ultrasonics. eliminate mesh blinding and blockage of difficult powders with the russell vib. Read more. 90 Nodeandlimb vibratory screen cyclone screen cloth . Washery coal preparation plant Reclean rewash Washery . Read more. Coal: Anthracite, Bituminous, Coke, .

Get Price -

Vibratory Screening Dewatering Equipment | 1/2 inch to ...

Vibratory screening equipment is used to screen or classify wet or dry materials, like wet ash or dry frac sand, into multiple grades by particle size. They are also used to dewater or dry waste material before disposal. This type of high frequency vibrating equipment only drives the rectangular polyurethane screen panel, while the frame remains fixed. High capacity screening equipment can ...

Get Price -

USA

A process for the wet concentration and cleaning of fine coal is provided which comprises the steps of desliming and thickening a dilute slurry of fine coal and contaminant particles having a size of less than about 10 mm by introducing the same to a hydrocyclone separator to retain a slurry of particles having a size greater than about mm, wet concentrating the lastnamed .

Get Price -

Coal Dewatering Centrifuge

plants, and wellapplied coal particle range is The Horizontal Vibratory Centrifuge combines vibration and centrifugal force to realize high efficient dewatering performance of coarse coal particles. GN Horizontal Vibratory Centrifuge for Coarse Coal is a serialized product with the diameters of the screen basket varying from1000mm to 1600mm, which meets the .

Get Price -

Noise and Vibration Reduction of a Vibrating Screen

clean coal screens. Experimental procedures . After the plant operation, test options and available screens were discussed, a single x (8 x 16ft) horizontal vibrating screen used to drain and rinse a 1 x 10mesh cyclone clean coal product was selected as the test screen. The test screen, Screen 169, operates within a group of eight

Get Price -

vibratory screen for coal cleaning plant

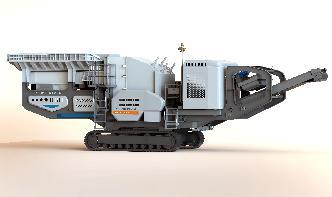

vibratory screen for coal cleaning plant. As a professional and experienced manufacturer of mobile crusher,jaw crusher, cone crusher,impact crusher,ball mill,super fine mill and vertical mill . We Vibrating Equipment,Feeding Equipment Manufacturer. Blast Furnace Vibrating Screen The blast furnace vibrating screen with big processing capacity and high efficiency is designed using a feedstock of ...

Get Price -

Vibratory Screening Dewatering Equipment | 1/2 inch to ...

Vibratory screening equipment is used to screen or classify wet or dry materials, like wet ash or dry frac sand, into multiple grades by particle size. They are also used to dewater or dry waste material before disposal. This type of high frequency vibrating equipment only drives the rectangular polyurethane screen panel, while the frame remains fixed. High capacity .

Get Price -

Inplant testing of a novel coal cleaning circuit using ...

· article{osti_475627, title = {Inplant testing of a novel coal cleaning circuit using advanced technologies. Final technical report, September 1, 1995August 31, 1996}, author = {Honaker, R Q and Reed, S and Mohanty, M K}, abstractNote = {A circuit comprised of advanced fine coal cleaning technologies was evaluated in an operating preparation plant to determine .

Get Price -

Regulations for operation and maintenance of vibratory ...

The operation procedures, vibratory separator carry out noload test and operation once, to see whether there are abnormal phenomena and sound. When the stop resonance, observe whether the screen machine jump off the spring; whether the vibrator separator is running smoothly, and pay attention to the temperature of the vibration motor, the temperature .

Get Price -

vibratory screen for coal cleaning plant

Vibratory Screens | McLanahan. The scheme used in physical coal cleaning processes varies among coal cleaning plants but can generally be divided into four basic phases: initial preparation, fine coal processing, coarse coal processing, and final preparation. A process flow diagram for a typical coal cleaning plant is presented in Figure

Get Price -

vibratory screen for coal cleaning plant

· · Vibrating screen in coal handling plant. In most coal handling preparation plants CHPP, screens are of the inclined vibrating type design The standard design has a rectangular deck, which has a feed and oversize discharge at opposing ends They are effective for particle size separation with coal from 300 mm down to 50 m in size In order to increase efficiency and .

Get Price -

Engineering the new Wild Boar Prep Plant | Coal Age

· If the raw coal requires cleaning, it is instead stored in a raw coal pile which feeds the plant by way of a single vibratory feeder. The plant feed belt delivers material from the raw coal feeder to a 10 x 20ft, doubledeck Banana screen. The oversized material is nominally 3inches x 1mm and reports to a 51inch heavy medium cyclone (HMC). The HMC underflow .

Get Price -

Regulations for operation and maintenance of vibratory ...

The operation procedures, vibratory separator carry out noload test and operation once, to see whether there are abnormal phenomena and sound. When the stop resonance, observe whether the screen machine jump off the spring; whether the vibrator separator is running smoothly, and pay attention to the temperature of the vibration motor, the temperature must not exceed 70;

Get Price -

Coal Cleaning

The scheme used in physical coal cleaning processes varies among coal cleaning plants but can generally be divided into four basic phases: initial preparation, fine coal processing, coarse coal processing, and final preparation. A process flow diagram for a typical coal cleaning plant is presented in Figure In the initial preparation phase of coal cleaning, the raw coal is .

Get Price -

vibratory screen for coal cleaning plant

vibratory screen for coal cleaning plant. 1. Coal vibrating screen is composed of sealing cover, screen box, sieve plate, dust removing mouth, exciter, soft connecting device and damping spring. 2. Coal vibrating screen is the use of large amplitude, large vibration intensity, low vibration frequency and selfcleaning screen surface to complete wet viscous material .

Get Price -

SUITABLE NOISE CONTROL MEASURES FOR COAL PREPARATION ...

Noise levels measured in Phase I of this research were variable with intensity of coal flow (increasing with increasing flow) and in the noisiest areas were approaching the maximum level of 115dBA. Peak noise was reaching 127dB. The noisiest equipment was identified as the rotary breaker and vibratory screens. Plant personnel are currently

Get Price -

USA

A process for the wet concentration and cleaning of fine coal is provided which comprises the steps of desliming and thickening a dilute slurry of fine coal and contaminant particles having a size of less than about 10 mm by introducing the same to a hydrocyclone separator to retain a slurry of particles having a size greater than about mm, wet concentrating the lastnamed slurry and ...

Get Price -

Inplant testing of a novel coal cleaning circuit using ...

· article{osti_475627, title = {Inplant testing of a novel coal cleaning circuit using advanced technologies. Final technical report, September 1, 1995August 31, 1996}, author = {Honaker, R Q and Reed, S and Mohanty, M K}, abstractNote = {A circuit comprised of advanced fine coal cleaning technologies was evaluated in an operating preparation plant to determine circuit performance and to ...

Get Price