-

Aggregate Production Process | Cornerstone Aggregates Inc.

The sand and gravel, undergo further complementary processing such as washing. The main purpose of this is to make the products clean. It is the only plant in the region that uses a Double Sand Classifier System for a cleaner and better quality sand.

Get Price -

Wyeville – HiCrush

WYEVILLE PLANT 8850 State Highway 173, Tomah, WI 54660 The Wyeville, Wi., production facility is capable of producing 2,700,000 tons per year of 20/100 frac sand. The facility is loed on 857 acres with coarsegrade Northern White sand reserves, onsite processing and rail facilities. The Wyeville facility produces multiple mesh sizes to meet customer needs, all of .

Get Price -

Sand Making Washing Process Plant

· Aggregate production line manufactured by aims for producing crushed stone aggregate. Crushed stone aggregate is produced from many natural . Sand and Gravel Plant + A construction sand gravel company committed to purchase a new processing plant for a new site to screen, wash and stockpile concrete sand and coarse aggregates. These finished products are used to satisfy the .

Get Price -

2016 aggregate production statistics : Pit Quarry

· Portable Plants Magazine; PQ on YouTube; PQ on Instagram; Customer Service FAQ; Road to Recovery. Road to Recovery Videos ; Your behavior appears to be a little unusual. Please verify that you are not a bot. 2016 aggregate production statistics. By PQ Staff | May 29, 2017. Crushed stone. In 2016, billion tons of crushed stone valued at more than billion was produced by .

Get Price -

aggregate processing equipment for sand, gravel ...

Toll Free USA/Canada Aggregate processing equipment for quarry, sand, gravel, rock, crushed stone, and mining. Buying and selling rock crushers, cone crushers, jaw crushers, screens, feeders, conveyors, generators, and spare parts. Dealer in Gator and Edison Machinery.

Get Price -

HiCrush Rolls Into Frac Sand's Final ...

· HiCrush Rolls Into Frac Sand's Final Frontier With MobileMini Plant Division Launch January 31, 2020 Infill Thoughts Leave a comment Since we first published this indepth primer on Jan. 17, 2020 about the "in field" frac sand mining opportunity, the industry's public conversation about mobilemini plants has gone from zero to sixty in a heartbeat.

Get Price -

The Quarry Story

We sell the crushed rock and sand to builders and contractors who use them to build roads, highways, bridges, houses, shopping malls, schools, churches and other buildings and structures. Words that are highlighted in the Quarry Story are defined at the end. Finding, Preparing and Designing a Site . Before we can start operating a quarry many preparations must be made. First, our geologists ...

Get Price -

Aggregates

Crushed Stone and Manufactured Sand. These products are obtained by mining rock and breaking it down to a preferred size. In the case of manufactured sand, the product is obtained by crushing rock to the selected shape or texture, ensuring product and project specifiions are met. Sources of crushed stone can be igneous, sedimentary, or metamorphic. Gravel. Gravel deposits are produced ...

Get Price -

Construction Aggregate Crushing Plant

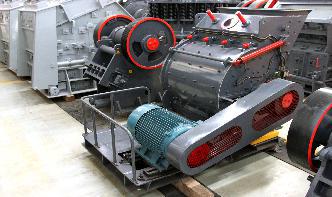

Aggregate Crushing Plant. is a premier supplier of crushing and screening equipment, and related auxiliary equipment in China. We provide complete crushers and screen machines for producing all types of aggregate. One unit of aggregate production line can produce up to TPH, the grain size will be 05mm, 510 mm, 1020mm, 20 ...

Get Price -

Oil Sands Extraction and Processing

Once the oil sand is crushed, hot water is added so it can be pumped to the extraction plant. At the extraction plant more hot water is added to this mixture of sand, clay, bitumen, and water in a large separation vessel where settling time is provided to allow the various components to separate. During separation, bitumen froth rises to the surface, where it is removed, diluted, and refined ...

Get Price -

Aggregates for Concrete

after minimal processing. Natural gravel and sand are usually dug or dredged from a pit, river, lake, or seabed. Crushed stone is produced by crushing quarry rock, boulders, cobbles, or largesize gravel. Crushed aircooled blastfurnace slag is also used as fine or coarse aggregate. The aggregates are usually washed and graded at the pit or plant. Some variation in the type, quality, cleanli ...

Get Price -

GreyHawk Design Fabriion | Custom Design Processing ...

GreyHawk Design Fabriion, Inc. was formed in 2008 to bring innovative process plant designs to the sand, gravel and crushed stone industry. With thirty years in appliion and sales of aggregate processing equipment, GreyHawk creates optimal plant designs with superior design features and userfriendly benefits. Superior Design and Attention to Detail. The design of a GreyHawk plant has ...

Get Price -

Crushing Plant

· Crushing Plant. Royal Engineering is one of the leading Manufacturers of Crushing Plant across the world. Since 1995 we have been leading manufacturer and supplier for Crushing Plant, Crusher Machine, Jaw Crusher, Grinding, Screening, Conveying Equipment, also Mineral processing plant equipments for the field of Mines, Quarry, Minerals ...

Get Price -

Crushed Sand Processing

sand processing crushed plant Silica Sand Processing Plant Flow chartTanzania . Silica Sand Processing Plant Flow chartShanghai XSM is aWashing plant will be applied to clean up the crushed silica sand . AP42 Section Crushed Stone Processing and ... Crushed Stone Processing and Pulverized Mineral Processing Process Description 24, 25 Crushed ...

Get Price -

Crushing Plant

· Royal Engineering is one of the leading Manufacturers of Crushing Plant across the world. Since 1995 we have been leading manufacturer and supplier for Crushing Plant, Crusher Machine, Jaw Crusher, Grinding, Screening, Conveying Equipment, also Mineral processing plant equipments for the field of Mines, Quarry, Minerals, Chemicals, Pharmaceuticals, Refractory and many other sectors .

Get Price -

The Nation's Top 25 Construction ...

· 10. New Enterprise Stone Lime Co., Inc. Top sand and gravel operators. A total of 868 million short tons of construction sand and gravel, valued at billion, plant, was reported ...

Get Price -

Valuation of Aggregate Operations for Banking Purposes ...

Sand and gravel was per ton varying depending on loion and grade from per ton to more than per ton loaded on trucks at the mine. The average mine produces approximately 200,000 tons per year, with crushed stone mines producing an average of .

Get Price -

Valuation of Aggregate Operations for ...

Sand and gravel was per ton varying depending on loion and grade from per ton to more than per ton loaded on trucks at the mine. The average mine produces approximately 200,000 tons per year, with crushed stone mines producing an average of 350,000 tons per year and the average sand .

Get Price -

How to Make Gravel and Sand

· The processing of extensive pit run gravel in many instances employs a permanent or semipermanent plant installation with a flexible system for movement of feed. The plant must be designed to produce a variety of product sizes and be capable of changing and blending products to meet varying customer specifiions or to compensate for variations in the pit conditions.

Get Price -

Sand Gravel washing plants from CDE Global

CDE Sand Gravel washing plants are being used across the world to maximise product yield and product quality and minimise waste . Customer Login. Region : Language: Search. Careers; About Us; News; Events; Brochures +44 28 8676 7900 Contact. Products. Wet Classifiion. EvoWash; Combo; FreeFlow Mobile Wash Plant; DLine Dewatering Screens; FLine Fine Screens; MSeries; Mobile Wash Plant ...

Get Price -

Vat Leaching of Finely Crushed Gold Ore

· Vat Leaching of Finely Crushed Gold Ore. Vat leaching is carried out in vats ranging in capacity from 30 to 1200 tons. Sand for leaching is separated from slime in cones, V boxes, classifiers, and in collecting vats filled by distributors—the overflow in each case being slime or finer portion of the ore. As a rule, leaching is a simple ...

Get Price