-

IRON ORE CHARACTERISTICS

Iron Ore Products > Two main groups of iron ore mined • High grade – Direct shipping ore ("DSO"), generally contains >60% Fe. It is used in blast furnace and only requires simple preparation. It is crushed for sizing and can be used either as fine ores or lump ore. • Low grade – (cutoff grades in the range of 2530% (1) Fe.) It is

Get Price -

Iron Ore Process Flowsheet Plant Design Indain Machinery

iron ore conveyor sampling system; 300 tph iron ore crushing plant in kenya malindi; iron ore process flowsheet plant design indain gulin machinery. Get Price And Support Online. 300 tph iron ore crushing plant in kenya malindi. Iron Ore Metallurgical Accounting Software Mining Machinery300 Tph Iron Ore Crushing Plant In Kenya MalindiIron ore ...

Get Price -

iron ore beneficiation flowsheet in india

iron ore beneficiation flow sheet india. Iron ore beneficiation flow sheet india apr fig a typical flow sheet of iron ore beneficiation plant some of the common methodstechniques applicable for iron ore processing are described below crushing grinding and screening technique the purpose of grinding and regrinding is to reduce the ore to a size small enough to liberate and.

Get Price -

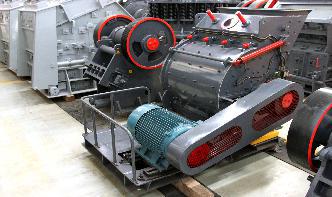

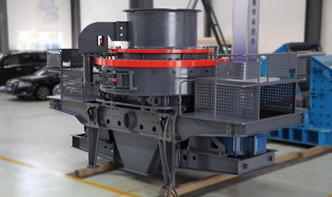

iron ore processing plant fines flowsheet stone crusher ...

Iron ore processing plant fines flowsheet iron ore processing plant fines flowsheet stone crusher apr 14 2017 iron ore crushing plantiron ore crusheriron ore beneficiation plant iron ore iron is found in the worlds oldest and most widely used is the largest amount metal the jaw crusher can improve the capacity maximize throughput andearn more.

Get Price -

iron ore processing plant fines flowsheet

iron ore processing plant fines flowsheet. The following diagram demonstrates some typical flowsheet designs for Iron Ore beneficiation of hard rock and friable ores Innovative Plant Design Having developed an effective and optimised flowsheet you need a plant that safely and effectively applies this flowsheet to the ore body to extract high grade iron ore whilst .

Get Price -

beneficiation flowsheet best

beneficiation plant flow sheet. Oct 02, 2019· beneficiation plant flow sheet. Basic Beneficiation Flowsheet For Iron Ore Best Beneficiation Flowsheet For Hematite Iron Ore mobility A typical flow sheet for iron ore beneficiation plant is shown in Fig 1 plays a major role in the evaluation of new ore bodies, process flowsheet development Get Price Kudremukh Magnetite Iron Ore .

Get Price -

Iron Ore Processing Plant Fines Flowsheet

Iron Ore Processing Plant Flowsheet. Iron Ore Processing Plant Flowsheet. The Silver Yards processing plant is designed to produce lump sinter and ultra fines products and operates on a seasonal weatherdependent basis from May to December. A conceptual delivery schedule of LIMs iron ore products during the. Read More

Get Price -

hematite iron ore processing flowsheet

Iron Ore Leaders in Mineral Processing Worldwide. The following diagram demonstrates some typical flowsheet designs for Iron Ore beneficiation of hard rock and friable ores Innovative Plant Design Having developed an effective and optimised flowsheet you need a plant that safely and effectively applies this flowsheet to the ore body to extract high grade iron ore whilst .

Get Price -

Iron Ore Processing Plant Fines Flowsheet

Iron Ore Processing Flowsheet, Iron Ore Beneficiation Plant Iron ore processing depend mainly on the type of ROM ore feed and optimum product. Dry screening into lumps and fines is practised for high quality flaky ore and blue dust, because, if wet treatment is used, a substantial part of good quality material is rejected in the form of slimes.

Get Price -

SINTERING AND PELLETISATION OF INDIAN IRON ORES

Process objective is to transform fine iron ore concentrate into pellets suitable to feed Blast Furnace or Direct Reduction plant or COREX. Pelletisation was invented to make use of Blue dust and ultra fine concentrate generated in the Iron ore beneficiation plants. Pellets have the benefit of lower gangue on account of

Get Price -

New dry iron ore processing technology developed ...

26/05/2016 · New dry iron ore processing technology developed. The mine tailing dam spill at BHP and Vale's Samarco iron ore operations last year killed 19 people and had devastating effects on the ...

Get Price -

Iron Ore Pelletizing Process: An Overview

depend on each ironmaking furnace and thoserequirements influence the operation ofthe iron ore pelletizing plant. The idea of rolling moist fine ore in a drum to form balls and then drying and firing it was first patented by A. G. Andersson in Sweden in 1912. Further development was performed to bring the idea to reality.

Get Price -

iron ore processing plant fines flowsheet

19/12/2020 · Hematite Iron Ore Processing Plant Flowsheet. Iron ore processing plant fines flowsheet iron ore processing plant fines flowsheet stone crusher apr 14 2017 iron ore crushing plantiron ore crusheriron ore beneficiation plant iron ore iron is found in the worlds oldest and most widely used is the largest amount metal the jaw crusher can improve the .

Get Price -

Ernest Henry Iron Ore 2011 Paper final

Iron Ore Conference Perth, WA 8 FLOW SHEET DEVELOPMENT AND EQUIPMENT In order to benchmark the proposed flowsheet and to understand the process risks and plant operation site visits to La Candelaria and Los Pelambres in Chile were undertaken. These

Get Price -

Production of High Grade Iron Ore Concentrates Using Flota.

forced iron ore producers to re examine their process flowsheets and evaluate alternate or supplemental ... In a recent study comparing the capital costs for a 620 tph flotation plant for treating iron ore fines, the following equipment requirements were identified. ... A scavenger column has been added to the flowsheet to maximize fine iron ...

Get Price -

Mineral Processing Flowsheets

08/03/2016 · The flowsheet showed the results obtained from testing a complex leadzinccopperiron ore containing values in gold. Exceptionally high grade and recovery were obtained in this instance. Utilizing a patented process special reagents made profitable production of lead/copper and zinciron concentrates and subsequent separation of these ...

Get Price -

Critical Issues With Water Iron Ore Beneficiation Plants

Critical Issues With Water Iron Ore Beneficiation Plants ... fine tailing 56Mtpa 28% Evaporation in the plant 10% of water used in plant ... Process Flowsheet > HPGR to 3mm > Coarse cobbing > Primary grind P80 55 µm > Intermediate magnetic separation

Get Price -

Beneficiation Plants and Pelletizing Plants for Utilizing ...

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII, Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept., Iron Unit Div., Engineering Business *2 Plant Engineering Dept., Iron Unit Div., Engineering Business *3 Ironmaking Dept., Kakogawa Works, Iron Steel Business

Get Price -

RTZ Iron Ore Mine, Hamersley Basin, Western Australia ...

The plant is designed to process approximately 12Mt/y of feed and achieve a 91% recovery on a dry basis. The Marandoo plant is designed to process up to 12Mt/y of ore into lump and fines products. The Marandoo flowsheet excludes a primary stockpile, facilitating the integration of mine/plant operations, especially product quality control.

Get Price -

iron ore processing flowsheet in johannesburg

20/08/2020 · Iron Ore Processing Flowsheet In Iron Ore Processing Flowsheet Iron ore is an important raw material of steel producers and these latest years,the iron ore processing plant is promoting very well. As a ore processing crops manufacturer, we can according to customers different needs, provide you with allaround tech support.

Get Price -

Flowsheet On Iron Ore Processing

15/11/2018 · 15/11/2018 · Iron ore processing plant fines flowsheet. Iron ore beneficiation flowsheet henan mining mach. beneficiation of iron ore lumps and fines by jiggi the first large scale iron ore jig beneficiation plant in india was missioned in 2006 at noamundi in the state of jharkhand tata steel is already operating a 300 tph fine ore jig iron ore plant there patnaik minerals also followed the .

Get Price -

Iron Ore Pelletizing Process: An Overview | IntechOpen

11/07/2018 · The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter .

Get Price -

iron ore processing plant fines flowsheet

Gravity Separation Unit at Itakpe Iron Ore Processing Plant, Nigeria Ajaka,, Akande,, and Saliu, M. A. results show that fines exist in the circuit as a result of the brittleness of some portions of the ore which leads to The materials used in the course of this project included the .

Get Price