-

Different Types of Machining Operations and the Machining ...

17/10/2021 · During the manufacturing of a part, a variety of machining operations and processes are needed to remove excess material. These operations are usually mechanical and involve cutting tools, abrasive wheels, and discs, etc. Machining operations may be performed on stock mill shapes such as bars and flats or they may be executed upon parts made by previous manufacturing methods such as .

Get Price -

Practical Lubriion of Open Gearing

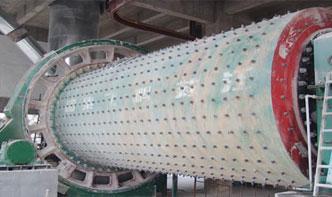

Open gearing appliions, particularly those associated with ball mill and finishing mill appliions, are considered some of the most difficult appliions a lubricant can encounter. Generally, these types of open gears operate at low pitch .

Get Price -

14 Types of Bearings: The Characteristics, Differences and ...

Paper making machinery, reduction gears, railway vehicle axles, rolling mill gear box seats, rolling mill roller tables, crushers, vibrating screens, machinery, woodworking machinery, various industrial reducers, vertical selfaligning bearings with boxes and so on. 4. Thrust Spherical Roller Bearings

Get Price -

MILLING OPERATIONS TYPES OF MILLING MACHINES

Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal. These machines are also classified as kneetype, cutter containing a number of cutting edges. The milling ramtype, manufacturing or bed type, and planertype. Most

Get Price -

Milling Fixture

19/11/2016 · Milling Fixture • Fixtures used to perform different types of milling operations are called milling fixtures. • Milling fixture is accurately loed and bolted on the machine table by using bolts and nuts. • The cutter is not guided during cutting operation. • Loion and clamping systems are similar to those used for drill jigs.

Get Price -

6 Types of Gearbox: The Ultimate Guide in 2021 | Linquip

17/02/2021 · Different Types Of Automobile Gearbox. Different types of gearbox in automobile are described below. Manual transmission; With a manual transmission, the driver selects all gears manually using both a movable gear selector and a driveroperated clutch. This type of transmission is also known as a "stick shift" or a "standard" transmission.

Get Price -

7 Different Types of Milling Machines

12/10/2021 · Milling machines come in various types with a variety of functions based on certain standard specifiions. Some of the most commonly used machines are the following: column, turret, Cframe, horizontal, bed type, planerstyle, and tracer controlled. A milling machine is a tool in the metal industry that has numerous functions. Each machine has a [.]

Get Price -

Gear milling

30/06/2013 · Form milling In form milling, the cutter called a form cutter travels axially along the length of the gear tooth at the appropriate depth to produce the gear tooth. After each tooth is cut, the cutter is withdrawn, the gear blank is rotated (indexed), and the cutter proceeds to cut another tooth. The process continues until all teeth are cut.

Get Price -

Total Guide to CNC Jigs, Fixtures, and Workholding ...

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills. Workholding is the generic term for any device used to firmly hold your workpiece while machining it. Closely related terms are "jigs" and "fixtures.". A fixture holds your workpiece while it is being cut. A jig holds the workpiece and also guides the cutter.

Get Price -

Milling Machine: Definition, Parts, Types, Operations ...

Milling machine is another most important machine tool after the Lathe machine tool and drilling machine.. In this machine, a multipoint cutter is rotating against the workpiece and material removed from the workpiece accordingly.. In today's article, you will learn about the definition, parts, types, and operation of a milling machine, also at the end of the article, I will add the ...

Get Price -

Gear milling | Find suppliers, processes material

Gear milling. Chipbreaking process of gears which are milled with cutters shaped like the tooth space. Beskrivning . The process. The round workpiece is mounted axially, perpendicular to the axis of the cutting tool. The tool is moved along the axis of the workpiece and mills out the gear tooth space. The work piece is then rotated by distance ...

Get Price -

kinds of gearing on milling

Gearcutting processes : a treatise on modern practice in cutting different types of gearing on standard milling machines and on special gearcutting machines of both generating and nongenerating designs by Franklin D. Jones Industrial Press, 1924. Learn More

Get Price -

Machining Center Spindles: What You Need to Know ...

01/01/2007 · Geardriven spindles add to the cost of the machine and can be noisier and require more maintenance than their competitor—the beltdriven spindle. There was a time when a geardriven spindle may have been preferred over a beltdriven spindle, but the advances in materials and belt design have proven it to be a low maintenance alternative.

Get Price -

UNIT 6 GEAR GENERATION AND FINISHING Gear Generation and ...

describe the gear milling, gear finishing, gear shaving, gear burnishing, roll finishing of gears process, explain the gear lapping and honing process, and understand the grinding of a gear. GEAR TERMINOLOGY The gear terminology is explained below with reference to a spur gear which is a particular type of a gear. The detail of gear ...

Get Price -

What are the Avantages of Milling: Benefit of Vertical and ...

02/03/2020 · Vertical mills are, again, egorized into two more types, namely, the turret mills and the bed mills. In case of bed mills, the material is kept on the bed, which can be moved forward and backward horizontally, and the cutter that is attached to the spindles are guided down and up. The other type is a turret mill, which comes with a bed and a ...

Get Price -

Types of Milling Operation | AS PRECISION

30/10/2019 · The milling cutter overhangs both sides of the workpiece. Partial Face Milling. Here, the milling cutter overhangs on the workpiece on one side only. End Milling. End milling primarily differs from other milling processes due to the type of tooling that is used for abrading a given material.

Get Price -

Gear Hardness Technology

tional gear cutting processes (nabbing. shaping. or milling) are capable of cutting materials with hardnesses of up to 400 BHN ..Though 400 BHN is machinable, gear teeth are much easier to machine when the hardness is lower. There will be di tortion ifthe hardening isdone after the teeth are cut The teeth may have to be finishmachined

Get Price