-

Frontiers | Prospective Life Cycle Assessment at Early ...

· The other operations ( grinding slag, CO 2 capture, mineralization and drying) are assumed to be performed at the same site. The second constraint requires to target the Japanese market if the calcination operation is loed in Japan. The scenarios that do not respect these constraints are removed from the set. Then, the two constraints reduce the feasible scenarios to 216. An extract of ...

Get Price -

Emission estimation technique manual

more energyintensive than dry processes. Preheater and precalciner kiln processes use dry grinding technology utilising kiln exhaust gases for drying. All kilns are equipped with grate or planetary type coolers which cool the fused clinker and recuperate energy for firing the kilns or drying raw materials. Over 70% of Australian Portland ...

Get Price -

DRY MAGNETIC SEPARATION TECHNOLOGY FOR THE RECOVERY .

universities and research institutes, the technique used for efficient recycling of iron mainly include dry magnetic separation of bulk slag, wet stage grinding and magnetic separation, wet magnetic separation for full grain level, finegrained level flotation, and gravity separation [79]. The wet separation and electromagnetic separation

Get Price -

Creep and drying shrinkage of a blended slag and low ...

· The main purpose of this research is to study the time dependent behaviour of a geopolymer concrete. The geopolymer binder is composed of % of low calcium fly ash and only % of ground granulated blast furnace slag. Both drying shrinkage and creep are studied. In addition, different curing conditions at elevated temperature were used. All experimental results were compared .

Get Price -

Metallurgical Slag pH Measurement

· Standard Technique used for pH Measurement. Weigh out a representative g sample of slag which has been powdered so that the entire sample will pass through a 100 mesh screen. The sample should be dry and free of contamination. Weighing of each sample is recommended in order to obtain reproducible results; however, an ordinary trip balance ...

Get Price -

(PDF) FERRONICKEL SLAG. USES AND ENVIRONMENT 68 | .

2. Drying, preheating and calcination up to 900 oC, approximately, as well as selective reduction of the iron and nickel oxides takes place in rotary kilns (R/K). 3. Reductive smelting of the calcine from the rotary kilns is taking place in open bath submerged arc electric furnaces, for the production of a low grade primary ferronickel alloy (~ 15% Ni) and a ferrosilicious slag. 4. Enrichment ...

Get Price -

Mineral Processing | CTP

Mineral Processing "Mineral Processing" is a discipline which implements a wide range of physicochemical methods the aim of which is to bring a product – primary (mineral) or secondary (waste) – to a state of direct use for the industry or for processing by a metallurgist. It can involve extracting or concentrating a metal from mineral, slag or electronic waste, or decontaminating ...

Get Price -

Grinding and Polishing Guide | Buehler

Grinding and Polishing Guide. Grinding should commence with the finest grit size that will establish an initially flat surface and remove the effects of sectioning within a few minutes. An abrasive grit size of 180240 [P180P280] is coarse enough to use on specimen surfaces sectioned by an abrasive wheel. Hacksawed, bandsawed, or other rough ...

Get Price -

Modern Processing Techniques to minimize cost in Cement ...

Modern Processing Techniques to minimize cost in Cement Industry Batra, Mittal, Kamal Kumar P N Chhangani Holtec Consulting Private Limited, Gurgaon INTRODUCTION Cement industry in the present scenario is under pressure due to increased competition, rising input costs, lower realisation and reducing profit margins. The need of the hour is to offset the continual increase in ...

Get Price -

Chapter 6 Copper Production Technology

Techniques . .....122 Summary of in Situ Copper Mining Activities . .....125 Smelter Technology in the ... 20300/o dry 3040°/0 reverb, 5075°/0 flash 9899 9899 Formation of the earth Concentration of copper in earth's crust Loion of economic resource Remove ore from ground and surrounding rock or overburden Creation of large surface area as preparation for flotation Removal of ...

Get Price -

Granulation and Heat Recovery from Metallurgical Slags ...

· Dry granulation requires far less cooling water, it is more compact and allows recovery of waste heat/energy from the molten slag. Dry granulation also avoids the emission of H 2 S and SO 2 with steam. The dry slag atomisation by air blasting has been commercialised in recent years and provides some attractive features.

Get Price -

Durability Properties and Microstructure of Ground ...

· It is well known that blast furnace slag cement (BFSC) has been manufactured by integrating GGBS with cement clinker or by separate grinding (Wang et al. 2005). For a long period of time, the appliion of GGBS was limited to the production of BFSC. Due to its less grindability, the surface area of the produced BFSC was even lower than that of commercial .

Get Price -

CNB

slag grinding production Prior art date Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired Fee Related Appliion number Other languages Chinese (zh) Other versions CNA (en Inventor Original ...

Get Price -

Fire Assay Procedure

· Fire assay procedures use a combination of intense heat (1900 °F) that is produced by a furnace, dry reagents called fluxes, and bone ash containers called crucibles and cupels. One uses this combination to fuse the fluxing agents and to isolate the precious metals. The ability to fire assay a substance relies on a number of facts. First of all, the samples that contain gold and silver should ...

Get Price -

The Optimization of Calcareous Fly AshAdded Cement ...

Grinding technique was used in cement produced using clinker, limestone, and fly ash. A type bond ball mill was used to grind cement material. After placing clinker, limestone, and fly ash in the mill, chemicals were added on top of the mix. Cement chemicals with grinding aid and strength enhancing properties were used in dosages of 200 and 800 g/t, respectively. Fly ash, on the other hand ...

Get Price -

Influence of Oxide and Silie Melt Phases on the RDI of ...

ray mapping technique was used to record the chemistry and distribution of different phases. 2. Pelletizing Process Production of iron oxide pellets from iron ore fines involves different operations like drying of ore fines to remove the moisture and grinding to get the required fineness. After mixing these ground ore fines with other addi

Get Price -

GRINDING TECHNOLOGY COURSE

It is necessary to grind clinker, gypsum, and sometimes other additives in the proportions required at a predetermined fineness in any cement grinding circuit. The fineness is usually defined by the cement's specific surface area measured in m²/kg or cm²/g. Highefficiency separators are usual to grind cement in a closedcircuit system due to energy consumption savings.

Get Price -

12 LABORATORY SAMPLE PREPARATION

drying, obtaining a constant weight, grinding, sieving, mixing, and subsampling) are discussed. Some sample preparation procedures then are presented for typical types of solid samples (, soil and sediment, biota, food, etc.). This chapter concludes with specific guidance for preparing

Get Price -

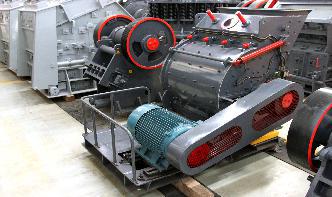

steel slag grinding

Metal Recovery and Filler Production from Steel Slag 2 This dry process developed by Loesche for recovering metals from steel slag combines all the advantages of conventional processes Dry grinding Loesche DGL Complete dry grinding of the mineral matrix . Online Chat steel slag grinding. Steel slag a byproduct of steel making is produced during the separation of the molten steel from ...

Get Price -

Manufacturing of Portland Cement – Process and Materials ...

· 1. Dry Process. In the dry and semidry process the raw materials are crushed in a dry state. Then, they are processed in grinding mill, dried and reduced to very fine powderlike. That dry power is further blended, corrected for the right composition and mixed with the flow of compressed air. Nearly about one hour of aeration, a uniform ...

Get Price -

The Optimization of Calcareous Fly AshAdded Cement ...

Grinding technique was used in cement produced using clinker, limestone, and fly ash. A type bond ball mill was used to grind cement material. After placing clinker, limestone, and fly ash in the mill, chemicals were added on top of the mix. Cement chemicals with grinding aid and strength enhancing properties were used in dosages of 200 and 800 g/t, respectively. Fly ash, .

Get Price -

How to Reduce and Remove Welding Spatter Easily – Make It ...

Grinding and Sanding. There are a ton of tools for grinding and sanding down weld areas. I'll just go over a couple of my favorites. An angle grinder with a flap disc is ideal for areas that are easily accessible. If you're welding tube or sheet metal, this will handle the majority of the work with ease. You can also use it to grind down ...

Get Price