-

Coarse Stone

This zone can net you a ton of Tin Ore, but in saying that, there's going to possibly be a lot of competition coming your way. While I don't personally go into caves, if you find competition on the outside, try going into the caves and nabbing the ore, as most farmers won't bother. Tin Ore 124; Coarse Stone 150; Silver Ore .

Get Price -

New and More Effective Grinding Bodies for Drum Mills

productivity for the fragmentation of coarse particle ore! This is because for the first time a combined Milling body 4 grinding spherical surfaces and with 10 breaking elements 6 edges and 4 top. Introducing the grinding body with edges placed Milling merits of a new unit at a high level in technological and

Get Price -

What Are The Main Factors Affecting Grinding Efficiency

31/05/2021 · The Influence Of Ore Properties. The composition and physical properties of ore have a great influence on the grinding technology efficiency, for example, when the useful minerals in the ore are coarse in size and loose and brittle in structure, they are easy to grind.

Get Price -

Grinding and pulverizing the ore is performed later in the ...

Dust control for the crushing and grinding processes is normally achieved by either wet suppression or LEV systems, or a combination of both. Spraying the ore with water sprays to coat the outer surface helps to prevent dust from becoming liberated. Applying the water to the ore before it enters the crushing or grinding unit is most effective. In addition, it has been shown .

Get Price -

High Pressure Grinding Rolls for Minerals

duty. In the iron ore industry, most of the machines are found in pellet feed appliions. However, there are a few notable examples where HPGRs are used for coarse iron ore grinding – in Chile, Mauritania and the USA. The first large scale attempt at applying HPGRs to harder and more abrasive copper and gold ores was in 1996 at Sierrita.

Get Price -

Crushing Vs Grinding

The comminution of smaller coarse particles is done by Cone, roll. Hammer crushers and rotary breakers. Grinding is conducted in mills. There are three grinding stages, coarse grinding (hundreds of microns), fine (tens of mictons) and ultrafine grinding (<10 microns). Tumbling mills, rotary breakers, and pendulum mills are mostely used.

Get Price -

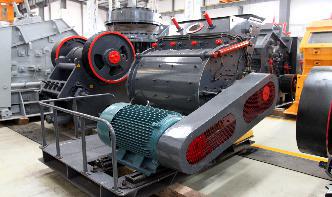

coarse copper ore grinding ball mill type

coarse copper ore grinding ball mill type,cedarapids crusher dealer,iro ore crusher supplier in Rwandac . Home; Products; Contact; What we do. We is a hightech company integrating RD, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in ...

Get Price -

||turkey coarse ore bin grinding machine||

chrome ore mining plant chrome crushing and chrome grinding. The crushing section for this 250 ton per day chrome mill consists of a coarse ore grizzly, a coarse ore bin with pan feeder to a 18 reduction crusher and a crusher discharge conveyor to a crushed ore bin.

Get Price -

Gold Ore Grinding Ball Mill For Rock Gold Mine ...

Gold Ore Grinding Ball Mill For Rock Gold Mine Benefiion, Find Complete Details about Gold Ore Grinding Ball Mill For Rock Gold Mine Benefiion,Ball Mill,Ball Grinder from Mine Mill Supplier or ManufacturerYantai Jinhe Mining Machinery Co., Ltd.

Get Price -

iron ore grinding coarse

iron ore grinding coarse [randpic] Mineralogical characterization of the typical coarse iron Coarse iron ore were efficiently upgraded by discharging waste gangue. ABSTRACT. Discharging waste gangue from coarse iron ore prior to subsequent upgrading and purifiion is ben

Get Price -

Mineral Processing

15/05/2014 · GRINDING: Breaking down of relatively COARSE CRUSHED ore to ULTIMATE FINENESS. The fineness of the ground product depends on the subsequent mineral beneficiation operations . Theoretically, PARTICLES SHOULD BE BROKEN DOWN TILL EVERY PARTICLE IS FULLY MINERAL ( VALUABLE ) OR GANGUE.

Get Price -

Analysis and validation of a runofmine ore grinding mill ...

of ne and coarse ore, where ne ore is smaller than the product speci ion size and coarse ore is larger than the product speci ion size. It is assumed that nes are essentially inseparable from the water found throughout the grinding mill circuit. Balls and rocks are only found in the mill, as they are too large to pass through the ...

Get Price -

IsaMill Technology Used in Effecient Grinding Circuits

IsaMill™ Technology Used in Efficient Grinding Circuits Burford1 and Clark2 High intensity stirred milling is now an industry accepted method to efficiently grind fine and coarse particles. In particular, the IsaMill™, which was invented for, and transformed the fine grinding

Get Price -

Factors affecting grinding throughput

26/05/2021 · The grinding media can be steel balls or rods or the ore itself as in autogenous grinding. Grinding is usually performed wet and when the mill is rotated ore and water, the mill charge, is intimately mixed. Several grinding steps, primary, secondary and tertiary, may be needed to achieve the desired size of the product.

Get Price -

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin ...

The geological grade of the ore deposit is relatively high (about 50%), but the ore body is thinner or has more interlayers. The waste rock is mixed in during mining to dilute the ore. For this kind of ore, only crushing and nogrinding can be used so coarsegrained tailings are discarded through reelection to recover the geological grade.

Get Price -

SAG Mill Grinding Circuit Design

06/06/2016 · AG/SAG throughput is defined by the unit power required to grind the ore to the closing size attained in the circuit. Very hard ores can severely constrain AG/SAG mill throughput. ... Four 1067 x 2400 mm vibrating feeders under the coarse ore stockpile feed the SAG mill via a 1067 mm feed belt equipped with a belt scale. Feed rate was initially ...

Get Price -

(PDF) How to Use Hard Ore Components as Grinding Media

Grinding circuit data and ore samples were collected from nine industrial ball mills of diameters m. For each of the ores tested there is a simple relation between the parameter and ...

Get Price -

coarse grinding m

coarse grinding definition English. According to the invention, coarse grinding stock present at the underflow of the hydrocyclone reaches a screening device after the first cyclone classifiion in order to carry out a second classifiion, wherein fine grinding stock that has been filtered out is separated and only the remaining coarse grinding stock is added to the mill circuit, and said ...

Get Price -

CHAPTER 1 MINERAL DRESSING

carried out by size reduction performed by crushers and grinding mills. The ore lumps from the mines have the lump size of 10 100 cm while the individual minerals have grain sizes below mm. Hence, the first step in any ore dressing plant is .

Get Price -

Industrial Grinding Estimation of Blended Ore from ...

Industrial Grinding Estimation of Blended Ore from Porphyry Copper Deposit Irena Grigorova1, Marin Ranchev2, Teodora Yankova3, Ivan Nishkov4* ... CL will provide a good compromise over grinding and minimization of coarse particles in the mill discharge [6].

Get Price -

feed grinder for laboratories in guam

Grinding Units one set of removable grinding plates 3371J35 and toothed feed for dry material Capacity 110 lbs per hour at a speed of 30 to 50 rpm Clamp attaches to table tops 13 to 38 mm thick Overall height 24 12 inches Model 3371H20 Worm Feed enables grinder to ...We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone ...

Get Price -

Grinding and pulverizing the ore is performed later in the ...

Grinding and pulverizing the ore is performed later in the mineral process to reduce the product down to the smaller size ranges, normally measured in mesh sizes. Grinding mills are used to perform this process and are cylindrical, horizontal drums that rotate and have rods, balls, or pebbles inside to grind the ore down to the desired size ranges. ...

Get Price -

Coarse Stone

This zone can net you a ton of Tin Ore, but in saying that, there's going to possibly be a lot of competition coming your way. While I don't personally go into caves, if you find competition on the outside, try going into the caves and nabbing the ore, as most farmers won't bother. Tin Ore 124; Coarse Stone 150; Silver Ore 11

Get Price -

Grinding Mills

20/03/2017 · The grinding medium may be steel rods, balls, or rock itself. Tumbling mills are typically employed in the mineral industry for coarsegrinding processes, in which particles between 5 and 250 mm are reduced in size to between 40 and 300 microns.

Get Price