-

Iron Ore Technical Centre

The ALS Iron Ore Technical Centre has been designed and built to accommodate scalable fused bead XRF processing capacity in excess of 10,000 samples per day. With specialist expertise in processing hematite, magnetite and all forms of iron ore, the centre provides extensive ore characterisation,

Get Price -

Iron Ore Wet Processing Plant In Australia

Iron Ore Wet Processing Plant In Australia. May 26 2016nbsp018332In doing this the company can produce a highly pure iron ore concentrate in an industrial scale by obtaining a premium product of up to 68 per cent iron as well as being able to make use of. Jaw Crusher.

Get Price -

Wet Vs Dry Screening Iron Orewet Vsdry Processing Iron Ore

Difference Between Dry And Wet Iron Ore. dry grinding of iron ore . cost of grinding by wet vs dry in iron ore. while the hpgrs are a dry grinding system, isamill is a wet grinding process .or finish grinding are on the iron ore, iron ore concentrate and gold ore sectors pared to the costs of a wet plant, the savings can amount to as much as nbsp.

Get Price -

Iron Ore Processing Flowsheet

The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing. The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method. The main objective of the primary beneficiation plant is the crushing of the ROM from the ...

Get Price -

what is a wet processing plant iron ore

What Is An Iron Ore Wet Plant. Managing ore variability in iron ore processing At Iron Ore 2017, a common concern across the industry was managing the shortterm variability of ore characteristics within deposits in iron ore processing, the flowon effects of unplanned processing issues, and the resulting downtime across the production cycle.

Get Price -

(PDF) Feasibility Study of Iron Concentrate Production in ...

Feasibility Study of Iron Concentrate Production in WTP Circuit from New and Old Wet Tailings of GolEGohar Iron Ore Processing Plant ... studies describing the processing of iron ores via direct ...

Get Price -

The Six Main Steps of Iron Ore Processing | Multotec Canada

14/03/2018 · When the iron ore is extracted from the mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher's CSS before the crushing stage. A static screen is used to divert the fine particles for crushing.

Get Price -

Managing ore variability in iron ore processing

04/10/2017 · As abovewatertable, highgrade ore deposits decrease in abundance, and producers increasingly start to extract ore from below the water table, the wet and sticky ore problem is having an increasing impact on the iron ore value chain. Wet and sticky ore can lead to a disrupted flow during processing and transport.

Get Price -

wet screening process of iron ore

iron ore wet screen plant YouTube. 22 Jul 2012 ... process plant, iron ore. Hemalite Iron ore plant. In order to increase the grade or capacity, several sets of wet drum plants and iron ores, wet. Read more

Get Price -

Wet ore: a sticky issue

13/05/2009 · Handling Wet and Sticky Ore (WSO) is a longstanding issue which has left many mining companies shrugging their shoulders and questioning how to address the problem.

Get Price -

Mineral Drying

Extracted ore, no matter the mineral, is typically first crushed, and then must go through a beneficiation process to remove the unwanted impurities. Beneficiation can vary significantly from one ore type to the next. In most cases, however, beneficiation is carried out through a wet process that necessitates a subsequent drying step.

Get Price -

Wet grinding process iron ore

wet vs dry iron ore mining Grinding Mill China dry and wet process iron ore Crusher Machinery For Sale HWC dry and wet process iron ore wet vs dry iron ore mining 171 views the is the professional mining equipments manufacturer in the world, loed in china,india, along with other asian processing iron ore tenova . Oline Chat

Get Price -

Iron Ore

Email Alex de Andrade at Proven Expertise. As a world leader in process solutions we have delivered some of the largest and most complex projects including design of the world's largest wet concentrating plant at the ArcelorMittal project, and the design and supply of two tailings treatment beneficiation plants for Arrium in Australia.

Get Price -

iron ore wet plant in australia

iron ore wet plant in australia [randpic] The case for wet processing iron ore HAVER Australia Depending on the ore type, quality and its degree of degradation, a washing and classifying plant can increase the iron content by two to five per cent, while reduc

Get Price -

Developments in iron ore comminution and classifiion ...

01/01/2015 · Even the DSO ores are requiring a higher level of processing as the depth of existing mines is increasing (below water table) where ores are wet and more sticky, which creates challenges for conventional crushing and screening. This chapter reviews the current state of iron ore comminution and classifiion technologies.

Get Price -

Environmental impact of iron ore mining

Roughly 98% of iron ore on the global market is used in iron and steel production. Mining and processing. Common methods of extracting the iron ore consist of blasting, drilling, or general excavating, Most iron ore is produced from openpit mines. After the iron ore is out of the ground, it may be shipped to the iron and steel manufacturing plant.

Get Price -

Wet beneficiation of low grade iron ores, or tailings of ...

In the process, low grade iron ores are dryground, preferably to their liberation size passed through a fluidized bed roaster. The process uses coal gas for preheating for partial reduction. Hematite / limonite / goethite ores get converted into magnetite ore in 110 minutes depending on the size of iron ore, at temperatures of 500600 ...

Get Price -

Iron Ore | Geoscience Australia

31/12/2018 · Iron (Fe) is a metallic element that constitutes % by weight of the Earth's crust and is the fourth most abundant element in the crust. Iron ores are rocks from which metallic iron can be economically extracted. The principal iron ores contain hematite (Fe 2 O 3) and magnetite (Fe 3 O 4). Hematite is an iron oxide mineral. It is nonmagnetic ...

Get Price -

Dry Iron Ore Beneficiation | Iron Ore Separation

Dry processing of iron ore presents an opportunity to eliminate costs and wet tailings generation associated with flotation and wet magnetic separation circuits. STET has evaluated several iron ore tailings and run of mine ore samples at bench scale (prefeasibility scale). Significant movement of iron and silies was observed, with examples ...

Get Price -

Wet Processing

Wet Processing. Our new generation DELKOR BQR flotation cells, equipped with our latest MAXGen mechanism, achieve superior metallurgical performance and assist in maximizing metal recovery. DELKOR BQR flotation cells achieve optimum operation through improved particlebubble interaction, faster flotation kinetics and precise froth level controls.

Get Price -

Iron Ore Processing

Iron Ore Processing 504. 6 Wet H igh Intensity M agnetic S eparation of cyclone underflow The cyclone under flow obtained from hydrocycloning condition was further treated in wet high intensity magnetic separator at current of . The results obtained are presented in .

Get Price -

BENEFICIATION OF IRON ORE

Processing of Iron ore in India 8 Slimes of Iron ore 11 3. BENEFICIATION PLANT STUDY OF NOAMUNDI ... Fig Wet screening classifiion 9 Fig Scrubbing wet screening classifiion 9 Fig Washing and gravity separation process 10 Fig Overview of ...

Get Price -

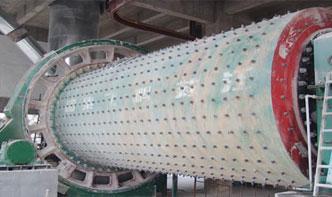

950tph Iron Ore Beneficiation Wet Processing Project in ...

05/08/2020 · The two wet processing plants at Iron Knob and Iron Baron, with a combined throughput of 950 tonnes per hour, were designed, manufactured and delivered within 18 months from signing – which was unprecedented for an Australian mining project of this nature.

Get Price -

Iron Ore Wet Processing Plant In Afghanistan

Iron Ore Wet Processing Plant In Afghanistan. Home > Ball Mill Sand Preparation Equipments > Iron Ore Wet Processing Plant In Afghanistan. Iran Steps In to Invest in Afghanistan Iron Ore Mine Financial Tribune Apr 3 2018 Back in December two iron ore processing plants were inaugurated in Sangan region. The first project was a 5millionton per ...

Get Price