-

iron processing

iron processing iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is ...

Get Price -

Investigation of Efficiency of Magnetic Separation Methods for Processing of LowGrade Iron ...

May 15, 2019 · In this research, the efficiency of magnetic separation methods for processing of a lowgrade iron pigments ore (red ochre) has been studied. Based on the mineralogical analyses (XRD), thin section and polish studies, the reserve is an iron sedimentary deposit with an average Fe grade of % The most valuable minerals are Hematite and Goethite and main gangue minerals are Calcite .

Get Price -

Iron Ore Beneficiation Processing Fundamentals – Informa ...

Iron Ore Beneficiation Processing Fundamentals . 1Day Training Course: A Technical Introduction to Iron Ore for Investors Industry Newcomers. Learn about the properties of hematite magnetite, their processing requirements, what makes them a saleable iron ore that's of market quality meets customer requirements

Get Price -

Iron Ore Materials Handling

Iron Ore Materials Handling Introduction. Materials Handling addresses the problems that arise when high moisture, sticky ores are transported through bins and chutes and onto ships across the supply chain. In such a system, the overall performance is only as good as the weakest link.

Get Price -

Mineralogy and textural impact on beneficiation of goethitic ore .

May 01, 2017 · As the demand of iron ore is increasing, it is necessary to recover the resources from the lean grade iron ore or goethitic ores through beneficiation. The correlation of mineralogy and texture to engineering parameters such as strength, comminution efficiency, product size and liberation was attempted [2], [3], [4] .

Get Price -

What Is Iron Ore Beneficiation? (with pictures)

Ray Hawk Raw iron ore has to be purified for use. Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal process of iron ore beneficiation has two complementary goals and these define the methods used to refine it.

Get Price -

iron ore beneficiation methods in china

iron ore beneficiation plant price | mining crusher equipment It (iron ore beneficiation plant price)is a global solution for your local needs. ... South Africa and other countries, but China is the world's largest iron ore demand for the country, there ... Currently uses three major iron ore beneficiation methods.

Get Price -

USA

A process for upgrading lowgrade magnetitecontaining iron ore with minimum fine grinding. The dry ore is first comminuted to between about threefourths inch and 10 mesh particle size and magnetically separated. The dry tailing is discarded and the concentrate is ground to between about 20 and 100 mesh and again subjected to dry magnetic separation.

Get Price -

JINDAL SAW LTD.

The low grade iron ore deposit of PurBanera Belt of Rajasthan has remained unexploited even though it was explored by Geological Survey of India, way back in the year 196970. After assessing the potential of Pelletisation of iron ore in India, Jindal SAW Ltd. a leader in India's Tubular market, planned to set up a MT Per Annum pellet ...

Get Price -

lead ore crusher plant beneficiation machine

· Treatment Methods of Lead Zinc Ore. Lead ore deposits in nigeria crusher lead ore testing machine in nigeria ore crusher plant lead ore mines in than 2000 years ago as a component of brass which is a zinc copper alloysulfide of lead ore plus the principal beneficiation methods can be .

Get Price -

(PDF) Beneficiation of Indian High Alumina Iron Ore Fines ...

International Journal of M ining Engineering and M ineral Processing 2012, 1(2): 94100 DOI: / Beneficiation of Indian High Alumina Iron Ore Fines – a Case Study C. Raghukumar1,*, Sunil Kumar Tripathy2, S. Mohanan1 1 Raw M aterial and Iron M aking Technology Group, Tata Steel Ltd., Jamshedpur, 831007, India 2 Research and Development Department, Tata .

Get Price -

Figure 2 from Beneficiation of a lowgrade iron ore by ...

Figure 2a. The lateral side of the first dump (2040% Fe) of mine B, b. The sampling tools, c. The sampling method. "Beneficiation of a lowgrade iron ore by combination of wet lowintensity magnetic separation and reverse flotation methods"

Get Price -

bentonite activation methods for iron ore pelletization ...

Jun 10, 2013 · Effects of bentonite fiber formation in iron ore pelletization. 1 Jul 2002 . You may be required to register, activate a subscription or purchase the article . Bentonite is a significant cost item in iron ore pelletization, and also . development method, and be used successfully as iron ore pellet binders. »More detailed

Get Price -

Beneficiation of Iron Ores – IspatGuru

Apr 03, 2014 · Several methods/techniques such as washing, jigging, magnetic separation, gravity separation, and flotation etc. are used to enhance the Fe content of the Iron ore and to reduce its gangue content. These techniques are used in various combinations for the beneficiation of iron ores. For beneficiation of a particular iron ore the emphasis is ...

Get Price -

Nevada Iron

US iron ore – global expertise. Nevada Iron is focused on the development of the Company's owned Buena Vista magnetite project. Loed in the mining friendly state of Nevada in the United States the project offers investors a low risk entry into an emerging steel mill feedstock.

Get Price -

iron beneficiation plant,iron beneficiation process

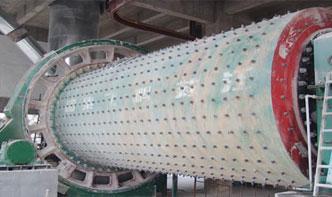

Heibei 5000 t/d Iron Ore Beneficiation Project. The qualified iron extraction of this project was obtained with Xinhai round vibrating screen Xinhai magnetic separator. Oversize middlings were sent to closedcircuit grinding system (including Xinhai wet grid type ball mill and hydrocyclone) for fine grinding.

Get Price -

Iron Ore Processing Plants

Iron Ore. Efficiently remove silica and alumina contamination to increase efficiencies in steel production. Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process.

Get Price -

History and Current State of Mining in the Kryvyi Rih Iron ...

Feb 10, 2021 · In 2021 one of the world's largest iron ore deposit in Kryvyi Rih (Ukraine) celebrates 140 years of its exploitation history. During the whole period of its existence the deposit has played and continues to play an important role in the development of Ukraine's economy, being the main basis of its iron and steel industry. More than 6 billion tons of marketable iron ore extracted during ...

Get Price -

Which Is The Oldest Method Of Beneficiation

Methods And Machinery Comparision In Iron Ore Beneficiation. each iron ore beneficiation method in 1990 Ryan 1991. a permit to install the equipment or process that will be the source of air contamination and a permit. Get Price; Spiral Concentrators Manufacturer For Coal Beneficiation

Get Price -

ncentration of iron ore beneficiation washing

iron ore beneficiation processes of washing. concentration of iron ore beneficiation washing. May 01 2017 0183 32 The high grade hematite iron ores require simple crushing and washing As the grade of ore is declining runofmine ore needs intense washing before shipment Depending upon the origin and mineralogical characteristics of the ore beneficiation methods vary from simple crushing ...

Get Price -

Potential Appliions for Dry Beneficiation of Iron Ore ...

Download PDF . ST Equipment Technology LLC (STET) triboelectrostatic belt separator technology allows for the beneficiation of fine mineral powders with an entirely dry technology at a high throughput. The STET separator is well suited for separation of very fine (<1µm) to moderately coarse (500µm) particles, in contrast to other electrostatic separation processes that are typically ...

Get Price -

Beneficiation of iron ore

Beneficiation of iron ore . United States Patent . Abstract: Iron ore is beneficiated using separation steps based on mineral composition without the use of separation steps based entirely on size. In a preferred sequence of steps the iron ore is passed from a ball mill through a magnetic separator where low iron content tailings are ...

Get Price -

Froth Flotation of Iron Ores

Jan 02, 2012 · With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market. In over half a century's practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron ore.

Get Price -

Iron ore

Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities. The results, highquality fine ore powders, are known as fines. Magnetite. Magnetite is magnetic, and hence easily separated from the gangue minerals and ...

Get Price