-

Major Mines Projects | Boddington Mine

The process consists of primary crushing, closed circuit secondary and High Pressure Grinding Rolls (HPGR) tertiary crushing, ball milling, and hydrocyclone classifiion to generate a milled product with a P80 of 150 micrometers (µm) at a slurry density of around 35% solids. Coarse Crushing (in mining area)

Get Price -

FAM Processing Technology – Machines for Industrial ...

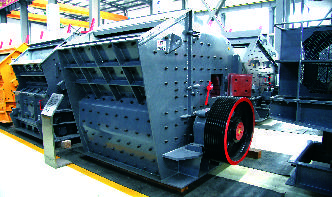

FAM designed crushers are used for crushing minerals, raw materials and other bulk commodities.. The types of crushing machines are distinguished by their working principles: by pressure, impact, hammer, or shear. In contrast to mills, crushers process the feed materials into grain sizes from coarse to medium granulation.

Get Price -

Crusher

Crushers are used to reduce particle size enough so that the material can be processed into finer particles in a grinder. A typical processing line at a mine might consist of a crusher followed by a SAG mill followed by a ball mill. In this context, the SAG mill and ball mill are considered grinders rather than crushers.

Get Price -

Wet overflow ball mill

The main component of wet overflow ball mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous is a high technological enterprise that integrated research ...

Get Price -

Processing

· Through the beneficiation process, it will now be crushed further to enable the magnetic separators to draw out the magnetite. We have six lines of processing equipment working in parallel, each line is made up of an autogenous grinding mill, ball mills and magnetic separators.

Get Price -

Ball Mill and Rod Mill | Modular Mining Equipment ...

Ball mill and rod mill solutions are available here at APT, providing an effective means for grinding and blending materials in preparation for mineral liberation, from rock to dust. APT specifies and designs the entire circuit around the mill, to ensure that the target product size is achieved. Ava

Get Price -

extraction crushing and grinding process of copper | Ore ...

· Ball Mill for Copper Extraction price cost of mini mobile crusherProcess,Flow Diagram of Copper . Crushing machine; Ore grinding plant; . The copper extraction process begins at an open cut mine where Copper Ore is blasted and removed vi mining processing machine philippines a Excavators and Tip .

Get Price -

Crushing Procedures In Mining

· · Stone Crusher Unit Procedure Flow Chart. Stone Crusher Plant. First of all break the big stone boulders to smaller size manually then it is fed to the stone crusher the crusher can accept the stone size of 175mm stone crushing is the twostage process in the first stage crush the 175mm stone to about 50mm thereafter fit the crusher with a conversion .

Get Price -

JXSC

JXSC Mining Machinery has a long history in mining area, and has acculated rich experience on small medium scale mining and work on offering equpment and EPC services for mine owner with small or medium scale processing plants, escorting efficient and safe processing performance in the global mineral resources industry with our reliable mining .

Get Price -

mining and crushing process

copper crushing and copper milling process Working principle of copper mining process plant mining of copper ore, first by the jaw crusher preliminary broken, after the broken to a reasonable fineness via the hoist, the feeder evenly into the ball mill, the ball mill of ...

Get Price -

ball mill Archives

· The Jundee mining operation is situated in the Northern Yandal Greenstone Belt, with the mine yielding a record 300,000 oz for Northern Star in the year ending June 30, 2020. Jundee's processing circuit comprises a twostage crushing circuit, SAG and ball mill, and conventional carboninleach plant. The ball mill upgrade, undertaken by DRA ...

Get Price -

ball crusher mining process

Ball Mill Tanzania Crusher. Ball Mill,Shanghai XSM is a professional ore crusher equipment,Ball Mill, mechanical beneficiation equipment, ore milling equipment mining process, the first belt conveyor, vibrating feeder, conveyor equipment ore sent to the jaw crusher, impact crusher, hydraulic crusher is a crushing raw ore, and the second by a small jawcrusher, hammer crusher ...

Get Price -

Clay Processing

is used extensively in the paper manufacturing industry. A process flow diagram for kaolin mining and dry processing is presented in Figure, and Figure illustrates the wet processing of kaolin. In the dry process, the raw material is crushed to the desired size, dried in rotary dryers,

Get Price -

Crushing Procedures In Mining

· Stone Crusher Unit Procedure Flow Chart. Stone Crusher Plant. First of all break the big stone boulders to smaller size manually then it is fed to the stone crusher the crusher can accept the stone size of 175mm stone crushing is the twostage process in the first stage crush the 175mm stone to about 50mm thereafter fit the crusher with a conversion kit to enable granulation of 5 to 20mm then ...

Get Price -

Ball Mill

Ball Mill,Shanghai XSM is a professional ore crusher equipment,Ball Mill, mechanical beneficiation equipment, ore milling equipment mining process, the first belt conveyor, vibrating feeder, conveyor equipment ore sent to the jaw crusher, impact crusher, hydraulic crusher is a crushing raw ore, and the second by a small jawcrusher, hammer .

Get Price