-

D930 Mobile Concrete Batching Plant

D930 mobile concrete batching plant is the latest product development in the Kimera product range and the first mobile discontinuous batching is normally mounted on 3axles semitrailers, with a capacity of at least 44 tons, and offers up to 15 m³/h of hourly production rate.

Get Price -

Daily Water Consumption Of Wet Concrete Batching Plant ...

Aug 10, 2017 · So it is necessary to recycle the waste water. The water used for cleaning vehicles is a big part of wet concrete batching plant. If it is assumed that cleaning a vehicle needs 12T water and it is washed 23 times a day and mediumsized concrete batching plant has 20 vehicles generally, it needs clean water 40120Tjust one day thereby washing ...

Get Price -

USA

A batch method of producing asphaltaggregate composition having a temperature of at least about 200° F. and at least about 20% used asphaltic concrete comprises heating solid particles of the used material in a first drum to a temperature of at least about 150° F., separately heating aggregate in a second drum to a temperature of less than about 400° F., and mixing the two materials ...

Get Price -

Ready Mix Batching Plants | MCT Group

The ready mix projects are developed in full partnership with the customer in order to optimize the site layout including trucks traffic and raw materials management. The batching plants are designed for a very flexible concrete production meeting the demand for fast and accurate batching of high quality concrete.

Get Price -

Mobile Cement Concrete Sand Batching Plant Precast ...

Our best selling batching plant is the F2200. This is a semi mobile batching plant. The F2200 is very popular with our recycling customers. It had four hoppers that can be used for recycling materials, sand and stone. Due to the output of the F2200 some of our customer recycle in the morning and cast precast concrete in the

Get Price -

Concrete Batching

Concrete batching is generally conducted at plants loed at various strategic positions around a city or town to minimize transport time. Raw materials are mixed in elevated bins and placed directly into concrete trucks for final transport. This process is primarily powered by electricity, with small amounts of other fuels used on each site by small excavators used to move raw materials, etc.

Get Price -

Cement Treated Base (CTB)

Nov 19, 2015 · The aggregate/granular material, cement, and water are typically mixed in a central mixing plant. Central plants can either be continuousflow or batchtype pugmill mixers. Pictured above, Woodruff and Sons, a general contractor loed in the state of Florida, USA, used the Rapidmix capabilities to produce high quality CTB using recycled ...

Get Price -

The 411 on Recycled Concrete: Uses, Benefits, and How To ...

RECYCLED CONCRETE USES. Old, unneeded concrete can be recycled and used to create recycled aggregate. In most cases, recycled aggregate will be used as a subbase material, but it can also be paired with materials and reused as an aggregate in new concrete. CA6 recycled PCC and Grade 8 recycled are common aggregates made from recycled ...

Get Price -

Portable Concrete Batching Plant

Twin shaft portable batching plant is simply consist of our JS twin shaft mixer and batching machine. Which have advantages in small investment, low risk, less land occupied and easy operation. This type of concrete plant can be used to produce dry hard, plastic lightweight aggregate concrete and all kinds of mortar, mortar mixing is suitable ...

Get Price -

QA on Hanson's proposed concrete washout recycling and ...

Jul 21, 2019 · Please list in dot point all the chemicals that are used in a Concrete Batching and Recycling plant? There are no chemicals used in concrete recycling other than those required for maintenance of the equipment used. Concrete batching requires mixing of aggregates, sand and water with cement or cementitious materials to produce concrete.

Get Price -

Concrete Batching Plant For Sale

Aimix concrete batching plants have capacity of 25240 m³/h, which mainly can be divided into mini type, stationary type, mobile type and drum concrete batching plants have been certified by CE, ISO, BV, etc, and have been exported to over 80+ countires includes: Philippines, Indonesia, Malaysia, Pakistan, Sri Lanka, Kenya, etc. Aimix provides presales, onsales .

Get Price -

Batching Plant: Types, Advantages Disadvantages

A concrete plant also known as a batch plant or batching plant or a concrete batching plant, is equipment that combines various ingredients to form concrete include water, air, admixtures, sand, aggregate (rocks, gravel, etc.), fly ash, silica fume, slag, and cement. Batching of concrete could be achieved by either weight batching or volume batching.

Get Price -

Concrete, Sand, Stone, Gravel and Construction Materials ...

Jul 19, 2021 · We are passionate about providing readymix concrete, sand, gravel, stone, blended soils, and related construction supplies throughout the East Coast. Our focus is to improve your business by going the extra mile delivering the finest products to you the first time, ontime, every time. MD/DC: VA: DE: .

Get Price -

Used concrete batching plants for sale: Readymix ...

1979 Rex Lo Profile 150 Batch Plant. 205Ton, 3Compartment, 10yard batch. Recently reduced to 65,000! Motivated seller. 65, Details. 2013 BMH Concrete Batch Plant. 5compartment aggregate bin. Weighed Water. 36" Belt.

Get Price -

McKinney council balks on proposed concrete recycling ...

Oct 05, 2021 · Initially, North Texas Natural Select Materials wanted to use the area for recycling and batch plant operations. However, the manufacturing or batching process was removed from the zoning request.

Get Price -

Concrete Batching Plants

Aug 30, 2021 · Custom manufacturer of concrete batching plants and fully integrated steel material handling equipment including truck hoppers, flex wall conveyors, aggregate storage bins, shuttle conveyors, weigh and volumetric batching equipment, color blending and batching systems, rapid pan mixers, mixer wash out systems, silos and dust control systems.

Get Price -

Treating and Recycling Concrete Process Water

May 29, 2010 · The unwritten rule when evaluating the suitability of water for use in concrete has typically been, "If you can drink it, you can make concrete with it." Many within the industry still have this perception and it is the reason why some customers may not allow the use of process water for batching, even though industry evaluations led to a ...

Get Price -

User Guidelines for Waste and Byproduct Materials in ...

Mar 08, 2016 · To reduce this problem, hot mix asphalt plants have been modified to permit the recycling of RAP. (24) In a batch plant operation, the RAP is usually added to superheated new aggregate at the pugmill. In drummix plants, RAP is usually introduced with new aggregate into the drum using a dual feed system.

Get Price -

Onsite batching plants | Hanson UK

All our plants can be supplied with a recycling unit to recycle water and recover aggregate from truck mixer washing, plant washing, and returned concrete. We can also put in place a number of measures to minimise dust and noise, including full cladding for the site batching plant. Delivering success. We can move many of our plants to any part ...

Get Price -

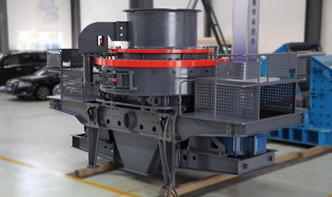

Different types and features of concrete batching plant

Dec 03, 2019 · A concrete batching plant can have a variety of parts and accessories, including: mixers (either tilt drum or horizontal or in some cases both), cement batchers, aggregate batchers, conveyors, radial stackers, aggregate bins, cement bins, heaters, chillers, cement silos, batch plant controls, and dust collectors.

Get Price -

Ways to Recycle and Reuse Concrete

Jan 07, 2019 · Recycled concrete can be used in many of the same ways as you would use new materials, such as gravel, paving materials, and aggregates. Permeable paving for walkways, driveways, and other outdoor hard surfaces: Broken concrete that is carefully laid creates a stable, porous traffic surface that rainwater can filter through.

Get Price -

Concrete

Concrete is one of the most recycled materials in the world that can be repurposed several times over. Once the existing concrete is demolished or torn up, it needs to be processed for accurate shaping and sizing using a crusher and screen.

Get Price -

concrete batching plants suppliers

Typical batch plants are used for ready mix, concrete recycling, civil infrastructure, maritime work, and precast appliions etc. Asphalt Mixing Plant We developed a number of series asphalt mixing plants, widely used in various grade highways and airports, dams and other places, with its highquality, quality service, by the majority of clients.

Get Price