-

Effect of Grinding Time of Mill Scale on the ...

This study deals with the grinding of mill scale in a laboratory ball mill for different milling time then briquetted by using 2% molasses as a binder and investigates the effect of grinding of mill scale for different time on the physicochemical properties and the reduction degree of the mill scale briquettes via hydrogen. Diffusion process control equation was applied and the energy of ...

Get Price -

TECHNICAL NOTES 8 GRINDING R. P. King

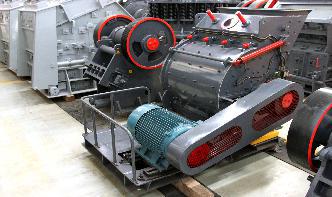

Figure Media motion in the tumbling mill. Grinding Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type. These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous. The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles ...

Get Price -

Effects of superfine grinding using ball‐milling on the ...

· Effects of superfine grinding using ballmilling on the physical properties, chemical composition, and antioxidant properties of Quercus ... and redness of the superfine QSL powder decreased with increasing ballmilling times, whereas the water solubility index, bulk density, tapped density, brightness, and yellowness were found to increase. Significantly higher P > ) total .

Get Price -

A study on the effect of process parameters in stirred ball mill .

stirred ball mill has been carried out. The effects of various operating factors, such as grinding time. (min), stirrer speed (rpm), slurry density (wt.%) and ball filling ratio on fine grinding ...

Get Price -

Inter Grinding Effects

Inter Grinding Effects. Sep 01 This paper describes the influence of the producing method intergrinding and separate grinding and particle size distribution PSD on earlyage properties of binary and ternary blended cements Various experiments were carried out to determine properties of cement paste including normal consistency time of setting heat of .

Get Price -

Analysis of the Effects of Grind Size on Production of ...

Grind Time Determination . The purpose of this was to plot a grinding time against grind size curve, to guide the grind size needed just by using residence time in the mill. A mill ball charge of 5kg of . of

Get Price -

Grinding Parameters and their Effects on the Quality of ...

used to clear grinding grain for measuring the fineness degree, mean weight diameter and size reduction ratio. Methods The hammer mill was evaluated at three sieve holes diameter (4, 6 and 8 mm) and three levels of corn moisture contents (10, 14 and 18% ).The mill productivity is determined by dividing the product mass by time; Mg/h.

Get Price -

(PDF) Effect of Milling Time on Particle Size and Surface ...

Effect of Milling Time on Particle Size and Surface Morphology of Commercial Zeolite by Planetary Ball Mill September 2013 Advanced Materials Research 795:711715

Get Price -

Effects Of Grinding Time On Milling

Effects Of Grinding Time On Milling. Reference Price: Get Latest Price. Compared grinding techniques in this investigation was hammer milling, with the screen size of 3 mm and hybrid milling. Hybrid milling was established by roller milling of mm distance between 2 sets of rollers, as the pregrinding process, and thereafter the hammer milling process with the screen size of. We provide ...

Get Price -

Effect of grinding aids on the timeflow characteristics of the .

· Variation of these flow parameters with the time of grinding can be used to analyse the timeflow characteristics of the mill material charge viewed from the point of bulk solids flow. Bulk densityThis is the basic characteristic of any bulk solid and can have a decisive influence on all other flow parameters. Hence, measurement of this is ...

Get Price -

Effects Of Grinding Time On Milling

Effects of grinding time on milling the effect of grinding time on the performance of the gold tailings were dried off in cs1013e dryer and grinded in wl1 microball dry grilling mill at the grinding time of 32 the effect of grinding time on the. Effects of dry grinding on the structural changes of . There was a limit to particlesize reduction with grinding time when grinding time was increased ...

Get Price -

Grinding Parameters and their Effects on the Quality of Corn for .

used to clear grinding grain for measuring the fineness degree, mean weight diameter and size reduction ratio. Methods The hammer mill was evaluated at three sieve holes diameter (4, 6 and 8 mm) and three levels of corn moisture contents (10, 14 and 18% ).The mill productivity is determined by dividing the product mass by time; Mg/h.

Get Price -

how speed of the ball mill affect grinding efficiency

ball milling effect: Topics by Various milling systems consisting of agate and polypropylene grinding ... The efficiency of a tumbling ball mill and a pin stirred mill were tested for comparison. ... Effect of tool stiffness upon tool wear in high spindle speed milling using small... Get Price. Grinding in Ball Mills: Modeling and Process Control Cybernetics ... Grinding .

Get Price -

Effect of grinding aids on the timeflow characteristics ...

· Variation of these flow parameters with the time of grinding can be used to analyse the timeflow characteristics of the mill material charge viewed from the point of bulk solids flow. Bulk densityThis is the basic characteristic of any bulk solid and can have a decisive influence on all other flow parameters. Hence, measurement of this is ...

Get Price -

Effect of Grinding Time of Mill Scale on the Physicochemical Properties of Produced ...

This study deals with the grinding of mill scale in a laboratory ball mill for different milling time then briquetted by using 2% molasses as a binder and investigates the effect of grinding of mill scale for different time on the physicochemical properties and the reduction degree of the mill scale briquettes via hydrogen. Diffusion process control equation was applied and the energy of ...

Get Price -

effects of grinding time on milling

Effect of Grinding Time of Mill Scale on the. Effect of the Grinding Time on the Reduction Percentage Figure 8illustrates the effect of change milling time on the degree of reduction of mill scale briquette at 900˚C (pressing load MPa) for different time and at 1 l/min. hydrogen flow rate.

Get Price -

Influence of Residence Time and Fine Grinding on PGMS .

mill was used to grind feed material to a specific particle size and distribution. Residence time test work diagram, FCTR without Deswik Mill Fig. 2 Mass balance diagram, FCTR without Deswik Mill International Conference on Ecology, Agriculture and Chemical Engineering (ICEACS'2012) December 1819, 2012 Phuket (Thailand) 219

Get Price -

effects of grinding time on milling

Effects Of Grinding Time For Mill Motor And Rotary Shakers. Effects Of Mill Feed Size And Rod Charges On Grinding. Feb 01 1992 It shows that when the grinding time is 1 min the feed size can strongly affect the product size as the grinding time is prolonged the coarsest particles will selectively be broken and its effect will therefore decrease After 4 min grinding the effect of the feed size ...

Get Price -

australia effects of grinding time on milling

effects of grinding time on milling effects of grinding time on milling Effect of ball and feed particle size distribution on the milling In this article the effect of grinding media size distribution and feed material particle size 3 shows the PSD for silica particles after milling at different tim...We are a professional mining machinery manufacturer, the main equipment including: jaw ...

Get Price -

Practical 1 : Ball Milling | TF Lab 1

· Particle size, number of balls, particle density, hardness, number of media used, time of grinding, and speed of the ball mill (rpm) are factors which will affect the process of milling. Size: The smaller the media particles, the smaller the particle size of the final product. Meanwhile, the size of grinding media particles should be larger than the material to be ground. Density: The grinding ...

Get Price -

Flexural and Morphological Properties of Poly(Methyl ...

· PMMA and HA powder are ground using planetary ball milling. The grinding time takes from 30 to 120 min. The effects of the grinding time and particle size of the PMMA/HA powder on the flexural properties and morphology of the composites are investigated. The structure patterns of PMMA/5HA are characterized using XRay diffraction (XRD). No new .

Get Price -

Optimization of mill performance by using

effect of slurry rheology and flow rate on mill behaviour. He had already highlighted the interaction between slurry and media in the mill by looking at the mill grinding efficiency. At that time, it was difficult to acquire a lot of valuable information as robustness in an aggressive environment was not assured. Twenty years later, the Sensomag is able to show this .

Get Price -

Effects of superfine grinding using ballmilling on the ...

Superfine grinding by ball milling for 24 h can thus be used to produce superfine QSL powder with higher free phenolic metabolite content and antioxidant activity, and improved water solubility index, color, bulk, and tapped densities. This study will be useful for the food / nutraceutical / pharmac . Effects of superfine grinding using ballmilling on the physical properties, chemical ...

Get Price -

effects of grinding time on milling

Effect of the Grinding Time on the Reduction Percentage Figure 8 illustrates the effect of change milling time on the degree of reduction of mill scale briquette at 900˚C pressing load MPa for different time and at 1 l/min hydrogen flow rate...

Get Price -

Flexural and Morphological Properties of Poly(Methyl ...

· PMMA and HA powder are ground using planetary ball milling. The grinding time takes from 30 to 120 min. The effects of the grinding time and particle size of the PMMA/HA powder on the flexural properties and morphology of the composites are investigated. The structure patterns of PMMA/5HA are characterized using XRay diffraction (XRD). No new phase is observed in the XRD .

Get Price