-

Clay Processing

mill is mixed with water and bulk loaded as a slurry for shipping. Figure depicts the process flow for ball clay processing. Indirect rotary or vibrating grate dryers are used to dry ball clay. Combustion gases from the firebox pass through an airtoair heat exchanger to heat the drying air to a temperature of approximately 300°C (570 ...

Get Price -

Mining and Mineral Processing at the Mount Polley mine ...

10/07/2020 · The larger particles flow to feed the ball mills while the fine particles report to two flash flotation cells. The ball mills are in "closed circuit", meaning that the discharge is pumped to the classifying units (primary hydrocyclones) and the particles will not pass to the next grinding stage until they are fine enough to feed through the ...

Get Price -

Cement Manufacturing Process Flow Chart

The cement manufacturing process flow chart is shown as follows: The whole cement manufacturing process is very complied, which mainly include seven steps as follow: Crushing And Preblending. Preparation Of Raw Material. Raw Material Homogenization. Preheating And Precalcining.

Get Price -

Ball Milling

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc .

Get Price -

Page 18 of 20

Copper Process Flowsheet Example. A simplified schematic drawing of copper flotation flowsheet. Runofmine open pit ore will be crushed in a gyratory crusher. The crushed ore will be processed by means of semiautogenous and ball mill grinding followed by rougher flotation, regrind, cleaner flotation, and dewatering to produce copper concentrate.

Get Price -

RD Scale Cylinder/Coin/Pouch Cell Production FlowChart ...

RD Scale Cylinder/Coin/Pouch Cell FlowChart with MTI's Battery Equipment Material Synthesis 1. Furnace to sinter: Rotary Tube Furnace with 100mm OD Quartz Tube, 1200C Max. OTF1200X4R 2. Ball mill to unify grain size: BenchTop Planetary Automatic Ball Mills with 4 Alumina Jars (4x500ml) MSKSFM1 Slurry Mixing Big Size:

Get Price -

Cement Manufacturing Process Flow Chart

07/01/2021 · The manufacture of cement is a twophase process. 8D4Ultrafine Grinder, Ultrafine Mill For Sale Clinker is first produced in a kiln system from calcareous (limestone, chalk or marl) and argillaceous (clay or shale) materials, with addition, in some cases, of small amounts of corrective materials (sand, waste bauxite, iron ore).

Get Price -

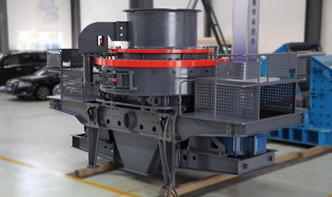

LHG roller mill is a new generation of powder processing equipment independently developed by our company, and its technical performance is qualitatively improved compared with multiroll mill. Low energy consumption: using innovative crushing mechanism, compared with multiroll mill, the output is increased by more than 30% under the same ...

Get Price -

Cement Manufacturing Process Flow Chart

The cement manufacturing process flow chart is shown as follows: The whole cement manufacturing process is very complied, which mainly include seven steps as follow: Crushing And Preblending. Preparation Of Raw Material. Raw .

Get Price -

process ball milling

A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining machines are used to grind or mix metals or raw materials for further processing. Inquire Now Milling Process, Defects, Equipment

Get Price -

Copper Mining Extraction Process Flow Chart

26/08/2015 · This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process.. Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore).

Get Price -

Chapter 18. Feed Milling Processes

The mill consists of a rotating shaft with four attached parallel knives and a screen occupying one fourth of the 360 degree rotation. The mill is best used to crack whole grains with a minimum of "fines". It is not used as a final process for reducing the size of ingredients used in fish feeds. Screening

Get Price -

Product Description. The LHE Wet Ultrafine Grinding Mill is a large size grinding machine independent rd by our company. Fully new grinding structure, unique component design, succinct process, it has qualitative improvement compare with other vertical wet grinding machine. With advantages of high grinding efficiency, fineness particle size ...

Get Price -

Ball Mills

A Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill. The larger the diameter, the slower the rotation.

Get Price -

Vertical Mill

gallon ball mill jar; products of pakistan steel mill 1633; vertical rooler mill detail description pdf stone crusher machine; ball mill coal industrial milling flow chart; new designed coarse grinding ball mill; traditional mill morocco particular; vertical hammer mill from malaysia; operating pressure of vertical raw mill; ball mill grinding ...

Get Price