-

Excavator, Underground Engineering Equipment, Mobile ...

Nov 29, 2020 · Sunward's scissor aerial work platforms have an automatic pothole protection system and a tilt protection system. Every single lifting operation can provide you a sense of safety ... open pit mining, crushing, channel dredging, hook digging, municipal works, auger drilling, precast piling, demolition, logging, ditching, etc. ... Mobile Crushing ...

Get Price -

Mining | Free FullText | A Framework for OpenPit Mine ...

Inpit crushing and conveying (IPCC) systems have drawn attention to the modern mining industry due to the numerous benefits than conventional truckandshovel systems. However, the implementation of the IPCC system can reduce mining flexibility and introduce additional mining sequence requirements. This paper investigates the longterm production scheduling and the crusher .

Get Price -

open pit mine conveyormobil crusher

open pit conveyor mobile crusher. Open Pit Mine Conveyormobil Crusher · In a fully mobile inpit crushing and conveying system an excavator loed on the muck pile loads material directly into the hopper of a mobile crushing plant instead of feeding a dump truck. Crushed rock is then transported to an inpit belt conveyor via mobile conveyors.

Get Price -

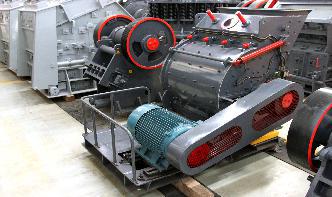

in pit and portable crushers

In Pit Crushing and Conveying Systems Belt Conveyors Widespread in SoftRock MiningTruck Haulage Versus Belt ConveyingInPit Crushers; The Key to hardrock ConveyingOperational Units Prove Concept Feasibility The essential task of the inpit crusher in a belt conveyor transport system is to reduce blasted material to a conveyable size. Crushers for this purpose are almost exclusively of the ...

Get Price -

Mobile crushing and screening plants to explore

Aug 26, 2021 · Aug 26, 2021 · The Mobi MC 110(i) EVO2, a mobile jaw crushing plant of a new generation from Kleemann, features a twostage overload system that effectively prevents blockages and material bridging that can lead to unwanted uncrushables enter, Kleemann says the closedside setting opens twice as fast as the predecessor plant or, as an .

Get Price -

Aggregate Equipment Manufacturer | ELRUS Aggregate Systems

ELRUS Aggregate Systems: Right on spec, right on time. For progressive aggregate producers and operators who know the value of maximizing 'in spec' production, ELRUS Aggregate Systems develops and delivers the most reliable crushing, screening and conveying solutions in the marketplace – a complete package of equipment, parts, mechanical services and technical .

Get Price -

Crusher,Mobile Crusher,Stone Crusher: The appliion of ...

The fundamentals of pit development are considered and comparative cases examined relative to conventional shoveltruck operations. The appliion of fully mobile inpit crushing systems is analyzed in terms of bench operations and their impact on mining costs and mine development. As an alternative, semimobile crusher options are compared.

Get Price -

Review of the inpit crushing and conveying (IPCC) system ...

The SMIPCC is a system where the inpit crusher is loed in the pit and is reloed after 12 years, ... The appliion of mobile inpit crushing and conveying in large, hard rock open pit .

Get Price -

small capacity in pit mobile crusher

The SMIPCC is a system where the inpit crusher is loed in the pit and is reloed after 12 years, depending on the operations of the specific mine (Tavakoli et al. 2011; Hay et al. 2019. Pit Mines Hard Rock Mobile Crusher modedesign . Pit Mines Hard Rock Mobile Crusher. Sep 09 2019the crusher was subjected to extensive tests with the ...

Get Price -

AMC – Mining Crushing

African Mining and Crushing will endeavour to preserve the health and safety of all persons affiliated with its activities, as well as the health and safety of any visitor. All work is to be performed under the direction and supervision of knowledgeable, suitably qualified staff, .

Get Price -

in pit crushing and conveying

Nov 13, 2020 · IPCC technology (In Pit Crushing Conveying system) The key to cost reduction and lower haulage cost in mining industry is an in pit crushing and conveying system (IPCC), a combination of track mounted mobile or semimobile crusher, with mobile and fixed conveyor belts. Below are the main advantages of IPCC systems to improve mining operations ...

Get Price -

SciELO

If the material is not friable, it is detonated, loaded into a primary crusher (mobile), or loaded onto trucks and transported to the primary crushing station (ex pit or semimobile in pit). Most continuous transport systems require a crushing machine that can be classified as mobile or semimobile set.

Get Price -

® Mobile Sizer

The Outotec ® mobile sizer proves it's flexibility by being a fully mobile crushing option. The track drive is always fueled by diesel and the sizer and other process components are electric driven. This allows the unit to move freely in the pit without external cables, which maximizes energy efficiency as well.

Get Price -

(PDF) A decisionmaking method to assess the benefits of a ...

This is due to the high installation REM: Int. Eng. J., Ouro Preto, 72(2), 285291, apr. jun. | 2019 289 A decisionmaking method to assess the benefits of a semimobile inpit crushing and conveying alternative during the early stages of a mining project cost of the crusher .

Get Price -

Inpit crushing and high angle conveying in Yugoslavian ...

Apr 27, 2007 · Mining operations and haulage systems have progressed in phases exploiting the most current technology. Phase I () haulage system was by trucks only. Phase II (1980 to present) began to exploit the favorable economics of waste haulage by conveyor from a fixed, pit perimeter crusher to the waste dump, with dumping by mobile spreader.

Get Price -

New Focus on InPit Crushing Systems

The existing inpit crushing system will be retained at least until the present concentrator is shut down and during this period a new semimobile inpit crushing plant will be installed in the northern section of the openpit, as well as a new crusher on the surface close to a stockpile feeding the overland conveyor to the new concentrator.

Get Price -

Inpit crushing with LT160

Apr 15, 2014 · The benefits of mobile inpit crushing. Construction of the new facilities at Peppertree started in July 2011 after more than a decade of planning. A risk assessment of the crushing process led to the selection of inpit crushing as .

Get Price -

Ultimate pit limit determination for semi mobile inpit ...

Jul 23, 2019 · Semi mobile inpit crushing and conveying systems have different pit shape requirements to traditional truck haulage systems due to the inclusion of a conveyor flight in the pit. As the shape of a pit is heavily influenced by the ultimate pit limit, it is desirable to have the additional shape requirements included in the ultimate pit limit ...

Get Price -

inpit crush and conveying systems

Aug 23, 2021 · We provide the strongest, longestlasting belts in a range of conveyor belt egories. WireMesh is the industry leader in custom engineered conveyor belt designs. Materials We also stress to provide ecofriendly materials wi ... Jquery UI Accordion Apply Now General Welder Must be able to read a tape measure ... History Of Wire Mesh .

Get Price -

In Pit Crushing Semi Mobile

Reloion of semimobile crushing plants in Indonesia and ... The demand for semimobile crushing plants for inpit crushing systems is increasing because of the rising transport costs for material, waste or overburden by large ...

Get Price -

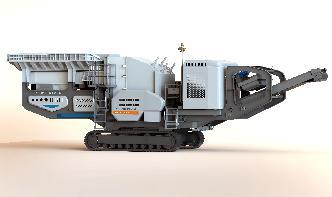

Inpit crushing and conveying saves more than just fuel ...

Apr 24, 2015 · In a fully mobile inpit crushing and conveying system, an excavator loed on the muck pile loads material directly into the hopper of a mobile crushing plant, instead of feeding a dump truck. Crushed rock is then transported to an inpit belt conveyor via mobile .

Get Price