-

Which is Better Sand Maker? Hammer, Vertical or Roll Crusher

Roll Crusher. Roll Crusher is a new type of sand making equipment. The material falls between the two rolls through the feeding port for extrusion and crushing, and the finished product falls naturally. In case of over hard or non crushing objects, the roll can automatically give way by the action of hydraulic cylinder or spring, so as to increase the rolls gap, and the over hard or non ...

Get Price -

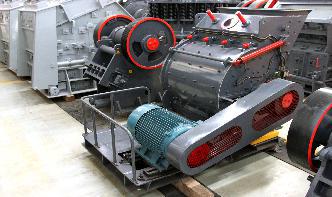

Double Roll Crusher From American ...

Double Roll Crusher. The American Pulverizer Double Roll Crusher is ideal for primary and secondary reduction of ROM coal, washed coal, middlings, screenings, slag, moist clay, limestone, cement, potash, rock, sulfur, lignite, pyrite, and other materials where minimum fines are required.

Get Price -

difference between single roll and double roll crushers

Single roll crushers are also available which rotate a single roll against a fixed breaker plate. Mineral or rock particles placed between the rolls are nipped and then crushed as they pass between the rolls. Double Roll Teethed Roll Crusher. Feb 24, 2016· The singleroll crusher has a tip speed of 400450 ft/min while the 6 x 7ft teethed roll crusher has a normal, noload, surfaces speed ...

Get Price -

Automatic Double Roll Crusher

Roll crusher machine has a theoretical maximum reduction ratio of 4:1. If a 2 inch particle is fed to the roll crusher, the absolute smallest size one could expect from the crusher is 1/2 inch. Toothed roller crusher will only crush material down to a minimum particle size of about 10 Mesh (2 mm). Some major advantages of roll crushers are they give a very fine product size .

Get Price -

Marcy® Double Roll Crushers | Laval Lab

Double Roll Crushers are useful for intermediate size reduction of hard to medium hard materials, such as rock or ore, after processing with a jaw crusher, for final reduction with a pulverizer. They also bridge the gap between laboratory and continuous production or pilot plant crushing capacities. Especially recommended for assay offices, metallurgical, soil and other .

Get Price -

Roll

18/10/2015 · Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1. If a 2 inch particle is fed to the roll crusher the absolute smallest size is 1/2 inch. Roll crushers will only crush material down to a minimum particle size of about 10 Mesh (2 mm). A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the Rolls. The particles are drawn into ...

Get Price -

Crusher

Roll crushers are very often used in limestone, coal, phosphate, chalk, and other friable soft ores. Figure Conceptual diagram depicting the basic elements of a roll crusher. The impact crusher (Fig. ) employs highspeed impact or sharp blows to the freefalling feed rather than compression or abrasion. It utilizes hinged or fixed heavy metal hammers (hammer .

Get Price -

Roll Crusher | HRC

Roll Crusher operation is based on the principle of continuous pressure generated between two counterrotating rolls; allowing uninterrupted crushing, in contrast to the intermittent action of jaw crushers. During operation, the high rotational energy of the crushing rolls and the drive components reduces peak loads, resulting in a more regular level of power consumption. If nonbreakable ...

Get Price -

What is the principle of roll crusher

Stone crushers, Jaw, Cone, Impact, Vsi crusher for What is the principle of roll crusher As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, What is the principle of roll crusher, quarry, aggregate, and different kinds of minerals.

Get Price -

Double Roll Crushers

Double roll crushers help producers achieve the strict coal specifiions they need to meet. Used as a primary or secondary unit, double roll crushers can be used in nearly any appliion with even the hardest, most abrasive material. This efficient crusher can lower power requirements for producing material and, with its unique features, can ...

Get Price -

Roller Crusher | Single/Double Roll Crushers

Rock Roll crusher is fine crusher equipment that similar to the hammer crusher. It can crush the compressive strength of less than 160 MPA of materials. Medium feed size, and adjustable discharge size. With the characteristic of low maintenance costs, low requirements for water, reliable performance, less power consumption, less dust, low noise and so on. Types of Roll Crushers. Stone roll ...

Get Price -

Roll Crushers | Gundlach Crusher Brand | TerraSource Global

MultiRoll Crushers are available with Gundlach's breakthrough 3D crushing technology that includes intermeshing continuous tooth roll design and positive roll timing that delivers the industry's best dimensional product control, fewer fines and elimination of oversize material.. Gundlach's roll crushers deliver higher quality cubical product, minimal fines and consistently repeatable ...

Get Price -

Roll Crusher | HRC

Roll Crusher operation is based on the principle of continuous pressure generated between two counterrotating rolls; allowing uninterrupted crushing, in contrast to the intermittent action of jaw crushers. During operation, the high rotational energy of the crushing rolls and the drive components reduces peak loads, resulting in a more regular level of power consumption. If .

Get Price -

Crusher | Article about Crusher by The Free Dictionary

Roll crushers appeared in England in 1806. Toothed roll crushers are used for brittle and soft materials such as coal and salt; they pull in pieces that are only times smaller than the diameter of the roller. Hammer crushers, or hammer mills, crush material by blows from hammers that are mounted by hinges on a rapidly turning rotor (the tip speed of the hammers .

Get Price -

X BJD DOUBLE ROLL CRUSHER

The used BJD 60/50 double roll crusher mill is in fair to good condition and available immediately ex site UK. Complete with 2 x 22Kw drive motors the used BJD double roll crusher model type 60/50 comes with 2 smooth spare rollers and associated spare parts and control panel.

Get Price -

Speed Of Roll Crushers

Roll Crusher Manufacturer Design Roll Crushers are simple in design and construction longlasting economical and versatile across many appliions and industries A combination of impact shear and compression are the forces necessary to perform the crushing and size reduction in a Williams roll crusher high speed roll mill vsi crushersRoll Mill High Speed Vsi Crushers .

Get Price -

Roll Crushers

01/01/2016 · Roll crushers consist of two or more adjacent rolls placed parallel to each other and rotated in opposite directions. Single roll crushers are also available which rotate a single roll against a fixed breaker plate. Mineral or rock particles placed between the rolls are nipped and then crushed as they pass between the rolls. Rolls are held against each other by springs. Radical changes to the ...

Get Price -

Roll crusher in Nuremberg, Germany

Roll Crushers are an economical way to crush material in a secondary or tertiary appliion. Roll crushers are compression type crushers with ratios of reduction up to 3:1. Contact Seller for Price. Sacramento, CA, USA. Used Crusher, Roll, 15" X 49", Gundlach, Single Stage, 2Roll, 40 HP (6)Crusher, Roll, 15" X 49", Gundlach, Single Stage, 2Roll, 40 HP (6) in Brisbane, CA (6) Gundlach Roll ...

Get Price -

difference between single roll and double roll crushers

Single roll crushers are also available which rotate a single roll against a fixed breaker plate. Mineral or rock particles placed between the rolls are nipped and then crushed as they pass between the rolls. Double Roll Teethed Roll Crusher. Feb 24, 2016· The singleroll crusher has a tip speed of 400450 ft/min while the 6 x 7ft teethed roll crusher has a normal, no .

Get Price -

CAA

A rollcrusher, wherein a roll is provided with rings of teeth spaced axially from each other which move between the teeth of a grating partly surrounding the roll on its underside and to one side; the grating being adapted to be swung out of range of the roll, teeth and being constructed to pivot about an axis, provided at the end thereof loed below the roll, into a position in .

Get Price -

Roll Crushers

Roll Crushers are compression type crushers, and were once widely used in mining. They have, within the last 10 or so years, fallen into disfavor among mining and processing companies. The probable reason is because the large mines require very large crushed product output with minimal cost, makes the roll crusher uncompetitive. The roll crushers are not as productive as cone crushers.

Get Price -

Toothed/Double Roll Crusher

Video of Fote Toothed Roll Crusher in Customer Site. For its tworoller structure, it is also called toothed roll crusher or double roll crusher. Fote toothed roll crusher can be divided into double roller crusher and fourroller series, customers can consult freely and get customized solutions according to their own needs.

Get Price -

Laboratory Dual Roll Crusher

Laboratory Dual Roll Crusher. Thank You! The Rolls Crusher will reduce rock samples to a fineness less than 20 mesh and smaller from original sizes up to 19mm maximum. This applies to 355mm rolls with the closest setting. It has a patent pending feed hopper to evenly distribute samples over the full surface of rolls to create uniform surface wear.

Get Price -

roll crushers conventional

Eccentric roll crusher I Crusher I thyssenkrupp thyssenkrupp . Compact reliable and powerful The new eccentric roll crusher type design 20 to 50 percent height reduction compared with conventional primary crushers . New ERC25 25 eccentric roll crusher revolutionizes primary . Summary thyssenkrupp has developed the new eccentric roll crusher ERC25 25 In the large .

Get Price