-

Grinding Media

Silicon Carbide Balls are very highcost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination. They are only available in 5mm,10mm, 15mm and 20mm sizes. They are a special order item.

Get Price -

(PDF) A parametric cost model for mineral grinding mills

Sayadi et al. (2014) introduced a parametric cost model for a mineral grinding mill by applying multivariate regression (Sayadi et al., 2014). Arfania et al. (2017), likewise has presented a ...

Get Price -

VMA

The actual dispersion system in a bead mill consists of a milling chamber and an agitator; the milling chamber is filled with the grinding beads (material glass, zircon oxide, steel) and the product to be dispersed. In the milling vessel, the grinding medium is kept moving by the agitator, which itself is driven by a motor.

Get Price -

cost of a grinding mill for flour

Cost Of A Grinding Mill For Flour powder Grinding Mill. Crushing Grinding And Reduction In Flour Milling The average lenght of the roller mill is based on the account of12mm 100kg 24 hours this account is valid for standard flour mills it varies according to the ratio of the products in the passages roller mill settings roller mill settings can ...

Get Price -

Open Circuit Configuration

IsaMill™ operations can take advantage of this feature which translates to an ability to use a low cost, but relatively low quality grinding media such as silica sand, river pebble, smelter slag or fine primary mill ss (autogenous milling). This means low media cost, with power efficiency still better than conventional grinding.

Get Price -

How Much Will a Flour Mill Project Cost

The cost for flour mill projects may range from as low as 5000 USD to as high as 60000 USD, depending on your individual project circumstances, like the flour milling process you choose, the equipment you buy, and more. For instance, a fully automatic flour mill plant will cost more than a simple flour mill plant.

Get Price -

a grinding mill cost

Get Price; Grinding Mill Design Ball Mill Manufacturer 911 Metallurgist. Jan 11, 2018 All Grinding Mill Ball Mill Manufacturers understand the object of the . steel rods and balls are a considerable part of the operating costs.

Get Price -

(PDF) A comparison of wear rates of ball mill grinding media

The grinding medium should provide maximum performance, minimum wear rate and highest grinding transfer to cost ratio (Jankovic, Wills, Dikmen, 2016). It is important to predict the rate of mill ...

Get Price -

How to Start Flour Mill Business? Cost Steps

The M6FX mini flour mill factory will cost 3,500 ~ 5,000. However, for the large scale flour mill factory, the cost definitely high. For example, the large scale flour mill plant equiped with automatic wheat mill machinery may cost 19,000 ~ 1,448,000 . But, this price is just for a references, the exact cos of the flour mill factory plant ...

Get Price -

grinding mill plant cost

Calcination plant cost – Grinding Mill Chinacost for a coal calcination plant. Home > Crusher Solution 08 > cost for a coal calcination plant Print Email cost for a coal calcination grinding mill plant cost

Get Price -

What's the Difference Between a Shaker and a Mill?

Make sure to only use the product the mill is designed to dispense – not all pepper mills should be used to dispense salt and vice versa. Adjust the grind coarseness to the desired texture. Loosening or tightening the knob at the top of the mill will ensure a larger or finer grind, meeting your customers' preferences each and every time.

Get Price -

Stirred mills for milling grinding | FL

Stirred mills Tower mills — simple, effective and cost efficient As lower ore grades and complex mineralogy are driving demand for more efficient fine grinding, you can depend on FL for a full range of finegrinding mills designed for easy shipment, simple erection and troublefree maintenance.

Get Price -

Cyclone Sample Mill

Maximum particle size mill can accept is 1/4". Grinding rate for a mediumhard product is approximately 3 g/s. Impeller speed is 12,600 rpm for 3383N90 and 10,400 rpm for 3383N92. The standard screen allows mm maximum particle size for delivery into sample container. Model 3383N90 and N92 mills are powered by a 3/4hp, beltdriven ...

Get Price -

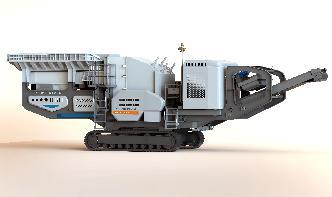

Grinding Mills

Fewer mills are, however, easier to control and capital and installation costs are lower, so the number of mills must be decided at the design stage. The high unit capacity SAG mill/ball mill circuit is dominant today and has contributed toward substantial savings in capital and operating costs, which has in turn made many lowgrade, hightonnage operations such as copper and gold ores feasible.

Get Price -

Stump Grinding Prices Cost Guide – Tree Removal

Our research shows that the average cost to grind a stump ranges from 100 to 400 per stump with an average price per diameter of 3. If you grind the stump yourself it may cost you as little as 75 to rent a stump grinder for half a day, or 250 to 400 for a full day.

Get Price -

How to Increase Grinding Mill Efficiency?

· This mill is widely used to grind any nonmetal minerals with Mohs hardness below 7 and moisture below 6%, such as talc, calcite, calciumcarbonate, dolomite, bentonite, kaolin, graphite, carbon black, etc. This kind of mill is especially suitable for ultrafine grinding.

Get Price