-

Modeling and optimization of fluidized bed and rotary dryers

Mar 01, 1997 · Rotary dryers are widely used for the continuous drying of minerals and chemicals on a large scale. Hot gases are passed parallel to the flowing solid to achieve the desired product moisture content. Because these dryers are energy intensive, it is mandatory to operate them as efficiently as possible to respond to economic pressures.

Get Price -

CoCurrent Vs. Counter Current Drying

One critical factor in designing a rotary dryer that produces the desired end product characteristics is the air flow configuration, or the direction in which the process gas flows through the dryer in relation to the material. Rotary dryers are available in two types of airflow configurations: cocurrent and counter current.

Get Price -

What is DDGS

Rotary Dryer DryMilling Average Ethanol Yield Per Bushel ( kg) of Corn Ethanol liters DDGS kg CO2 kg Slide courtesy of Ms. Kelly Davis, CVEC, Benson, MN "New Generation" Ethanol Plants are Loed in the Western "Corn Belt" of the DDGS Production is Rapidly Increasing 0

Get Price -

Fine Points of Direct Fired Dryers

Jun 25, 2021 · COUNTER FLOW. Counter Flow Dryers are used when the product size is larger or the size is mixed from large to small. In these dryers, product moves downhill against the gas flow. These dryers are more efficient and have lower gas discharge temperatures compared to the material discharge temperature (cool material enters the dryer and cools the gas flow as it leaves the dryer).

Get Price -

Selecting Rotary Direct Heat Dryers |

The dryer is used not only to dry, but also to bring the rock and sand up to temperature. Therefore, a counterflow design is typically used. There are more rotary dryers in the hotmix asphalt industry than any other design. If you are looking for a used dryer, this is what is typically most readily available.

Get Price -

What is Heat Exchanger Analysis

May 22, 2019 · Consider a parallelflow heat exchanger, which is used to cool oil from 70°C to 40°C using water available at 30°C. The outlet temperature of the water is 36°C. The rate of flow of oil is 1 kg/s. The specific heat of the oil is kJ/kg K. The overall heat transfer coefficient U = 200 W/m 2 K. Calculate the logarithmic mean temperature ...

Get Price -

top 10 largest counter flow wood dryer brands and get free ...

best indian human hair supplier in chennai list and get free shipping

Get Price -

Countercurrent exchange

Countercurrent exchange is a mechanism occurring in nature and mimicked in industry and engineering, in which there is a crossover of some property, usually heat or some chemical, between two flowing bodies flowing in opposite directions to each other. The flowing bodies can be liquids, gases, or even solid powders, or any combination of those. For example, in a .

Get Price -

Drying Systems

In a spray dryer, liquid or fine solid material in a slurry is sprayed in the form of a fine droplet dispersion into a current of heated air. Air and solids may move in parallel or counter flow. Drying occurs very rapidly, so that this process is very useful for materials that are damaged by exposure to heat for any appreciable length of time.

Get Price -

Distillery | Dryers For Distillery, Evaporators Dryers For ...

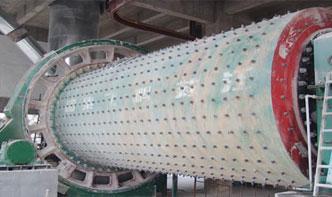

The dryer is a cylinder that is slightly inclined from the horizontal direction. The material is added from the higher end. The hightemperature heat source and the material flow parallelly or counterflow into the cylinder. As the cylinder rotates, the material flows to the lower end.

Get Price -

Steam Tube Dryers

Steam tube dryers utilizing steam rather than hot gas and its direct heat source has enabled the steam tube dryer to operate up to 95% thermal efficiency. In some instances, the steam tube dryer method is superior to other direct and indirect heat methods. ... in both parallel and counterflow arrangements. ...

Get Price -

Dryer | Kilns, Furnaces, Dryers | Product Lineup | Ube ...

There are rotary dryers with a rotating horizontal barrel and vertical dryers. Most have a barrel measuring 1m to 5m. There are also parallelflow dryers and counterflow dryers. Handling is easy, enabling extended, consecutive operation; Perfect for processing large capacity;

Get Price -

Asphalt Drum Plant | Asphalt Drum Mix Plant | AIMIX ...

Counter flow drum mix plant provides better pollution control, fuel saving and superior quality of hot mix compared to the parallel flow hot mix plant since the material flow in the drum is opposite to the direction of exhaust gases, and the liquid asphalt, aggregate and RAP are mixed in a zone removed from direct contact with hot exhaust gases.

Get Price -

Heat Exchangers

In the parallelflow arrangement of Figure (a), the hot and cold fluids enter at the same end, flow in the same direction, and leave at the same end. In the counterflow arrangement of Figure (b), the fluids enter at opposite ends, flow in opposite directions, and leave at opposite ends.

Get Price -

Direct Fired Rotary Calciners Heat Transfer Equipment

An indirectly heated rotary dryer is essentially the same arrangement as the indirectly heated calciner, but is designed for operation at. Prices / Quote. Kilns Calciners. 86 diameter x 30 long oil fired rotary calciner, manufactured by John Munn USA, serial 14716, parallel flow design, drum speed 0,7 0,73 rpm, operating temp 1000 deg C, oil ...

Get Price -

Rotary Dryer Colombia Industrial Dryer Manufacturer,

HCG Series Rotary Dryers characteristics: Volumetric heat transfer coefficient is 155 times of rotary parallel flow drier, up to kcal/cmC h, theheat efficiency is high The drying time is short, the staying time of material may be inherently regulated, moisture content is easy tocontrol The granularity of material remains intact. More

Get Price -

How to Calculate the Log Mean Temperature Difference in ...

Feb 01, 2012 · The log mean temperature difference is normally calculated from the terminal temperature differences. For Counter current flow: For Cocurrent flow. Reference: D. Q. Kern, Process Heat Transfer, McGrawHill, International Edition, 1950. Free LMTD Calculator.

Get Price -

Heat Exchanger

The counter flow or parallel flow arrangement can also be possible. The fins may be plain fin (Straight or corrugated) or interrupted and are attached to the plate by brazing or soldering. They are more suitable for gas to gas appliions. Plate fin type heat exchanger is as shown in figure.

Get Price -

Parallel and Counter Flow Designs Heat Exchangers

Parallel and Counter Flow Designs Heat Exchangers Although ordinary heat exchangers may be extremely different in design and construction and may be of the single or twophase type, their modes of operation and effectiveness are largely determined by the direction of the fluid flow within the exchanger.

Get Price -

Rotary drum dryer: the much appreciated versatile work ...

Rotary drum dryers work with cocurrent heating where product and hot gas flow in parallel through the drum. Alternatively, they operate in countercurrent mode, where hot gases circulate in opposite direction of the product direction. The ultimate configuration depends on the process requirements and how much the product may heat up.

Get Price -

ANDRITZ Counter flow cooler

The ANDRITZ counterflow cooler solutions ensure the correct temperature of pellets prior to storage. The vertical cooler is suitable for optimum cooling of extruded or pelletized products based on customer appliions and preferences. It prepares the the pellets optimally for storage and is one of the cleanest solutions due its discharge system.

Get Price -

(PDF) Control of Industrial Dryers | Vijaya Raghavan ...

Convective rotary dryers are normally controlled by the measurement of exitgas temperature, which is SPRAY DRYERS used to regulate the inletair temperature; the pressure is adjusted by the exhaust damper setting, and the The residence time in spray dryers is short and the inletair rate is used to control the outletair wet small ...

Get Price