-

Home

Established in the year 1989, Maxwell Crushtech has covered a long journey to become one of the noted Exporter, manufacturer, Service Provider and Supplier and Trader of stateoftheart Stone Crushers, Grizzly Feeder, Vibrating Screen, Horizontal Shaft Impactor (HSI), Vertical Shaft Impactor (VSI), Loader, Grizzly Feeder, Reciproing Feeder (HSI), Loader, Feeder etc.

Get Price -

Compost fertilizer manufacturing process | compost turner ...

The vertical crusher is our patent equipment, whose crushing degree is adjustable. The hammer crusher is suitable for dealing with large scale compost fertilizer. Screening equipment for compost fertilizer: SEEC mainly manufacturing two types screening equipment, rotary screen machine and .

Get Price -

How to Start Sand Manufacturing Business

The Jaw crushers are generally used for crushing stones into metal/aggregates. Manufactured sand from jaw crusher, cone crusher, roll crusher often contain a higher percentage of dust and have the flaky particle. In unit setup, you will require a minimum of 30,000 sq ft of land. It requires high voltage electricity to operate the machines.

Get Price -

M sand crusher business project

May 06, 2021 · M sand crusher have to produce manufactured sand from stone. This article is comprehensively analyzing the business ideas of MSand and PSand crusher. Manufactured Sand (MSand) are produced and artificially created by crushing rocks and quarry stones.. Two types of sands are produced in this way.

Get Price -

The Complete Guide to Crushed Stone and Gravel

Nov 11, 2019 · Like crushed stone, gravel can be used as an aggregate for pavement, ready mix concrete, or other construction appliions. Best appliions for crushed stone We have already referenced many places where crushed stone is used, but the most common are construction projects that need concrete, solid bases, or drainage systems.

Get Price -

ppt aggregates crushers and manufacturing

Crusher|Ppt Aggregates Crushers And Manufacturing Steps. Lightweight Aggregate Manufacturing Process Description1,2 Lightweight aggregate is a type of coarse aggregate that is used in the production of ... The material is crushed with cone crushers, jaw crushers, hammermills, or pugmills and is screened for size.

Get Price -

Aggregate Crushers, for Rock, Ore Minerals

Portable Crushers is a new line of Hammermill and Jaw Crushers that offer rugged construction, portability and versatility of use. All can be equipped with gasoline, diesel, or electric power. Marcy® Lab Cone Crusher is ideal for reducing aggregates and mineral ores. The Marcy® GYRoll 6in (152mm) or 10in (254mm) Lab Cone Crushers have 300lb ...

Get Price -

Crusher, Crushing plant

jaw crusher. 130 5 mm | BB 300. RETSCH jaw crushers are used for the rapid, gentle crushing and precrushing of mediumhard, hard, brittle and tough materials. They are primarily used in laboratories and pilot plants under rough conditions but are also ... Compare this product Remove from comparison tool.

Get Price -

Aggregates | McLanahan

Construction aggregates are also produced as byproducts from other manufacturing processes such as steel mill slag. Why McLanahan In the mining business since 1835, McLanahan employs a team of process design experts who are able to help you create a more efficient, more productive and more profitable site.

Get Price -

Crusher How Works Aggregates

Aggregate Crushing Plants Jaw Crushes And Impact Crushers. An aggregate screener separates all kinds of materials into grades stackers stockpile materials using either an aggregate conveyor or conveyor belts for the construction and mining industry crushing plants such as jaw crushers impact crushers and cone crushers bust open ore so that minerals can be extracted and also for processing .

Get Price -

Home

Ace Equipment Sales, Inc. was founded by Lawrence "Larry" Becker in 1973. By that time, Larry had been operating a gravel pit, granite quarry, and a concrete manufacturing plant for nearly two decades. Larry has sold equipment all over the world and developed longlasting relationships close to home.

Get Price -

Contract Crushing; Crusher Parts, Leading ...

Mellott Company exists to help our clients crush more, through Contract Crushing, Portable Crushing, Rock Crusher Parts, Equipment, Performance Systems, and More!. We conduct our business by a philosophy we call "Values Based Leadership" (VBL). Our values are: Safety, Integrity, Commitment, Respect, and Excellence, which serve as the five pillars for our .

Get Price -

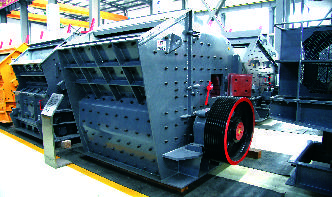

Impact crushers and impact mills with a horizontal shaft ...

Impact crushers and impact mills of type PB and PM are universal and, at the same time, economical solutions. The impact crusher achieves very high crushing ratios in both the first and second stage. This results in a wide range of salable, cubical final products. The impact crusher can be repurposed into an impact mill for manufacturing fine ...

Get Price -

Aggregates in monoclonal antibody manufacturing processes

In this review it is analyzed how aggregates are formed during monoclonal antibody industrial production, why they have to be removed and the manufacturing process steps that are designed to either minimize or remove aggregates in the final product.

Get Price -

Powerscreen | Crushers | Screeners | Conveyers

Powerscreen is the world's leading manufacturer of crushers, screeners, and conveyors for the aggregates, recycling, and mining industries.

Get Price -

Crusher Manufacturers in India | – Stationary ...

Oct 24, 2019 · The various kinds of crushers available in the market are: Primary Jaw crusher: It is used for processing hard and abrasive materials like granite and ores. It is also used for recycled concrete. Cone crushers: In some cases, it is used for hard materials but is bettersuited appliion dealing in secondary crushing.

Get Price -

Impact crushers and impact mills with a horizontal shaft

The impact crusher achieves very high crushing ratios in both the first and second stage. This results in a wide range of salable, cubical final products. The impact crusher can be repurposed into an impact mill for manufacturing finer grains by inserting a higher machine base and an additional grinding track.

Get Price -

Impact Crusher Cement Manufacturing

Impact Crusher Cement Manufacturing. The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. ... Impact crusher is a kind of crushing machine which uses impact energy to break materials. It is suitable for handling brittle materials of medium hardness with side ... The raw material ...

Get Price -

cement manufacturing

The proportional ratio of the raw materials is fixed using raw mix design and is determined from the chemical analysis of the raw materials. The raw materials stored in individual feed bins are proportionally delivered through weigh feeders at the discharge of the bins to a belt conveyor or a feeder feeding the mill for subsequent drying and ...

Get Price -

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012 · Crusher reduces the size of large rocks to the size of gravels. Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding.

Get Price -

Pdf Operation Steps Of Aggregate Crusher

Pdf Operation Steps Of Aggregate Crusher Home Pdf Operation Steps Of Aggregate Crusher PEW series Jaw crusher features big crushing ratio, reliable .

Get Price -

Crusher Manufacturing Companies | Crusher production .

Crusher Manufacturing Companies Mewar Hitech is a leading and pioneering enterprise providing topnotch services in the industry. The decisive elements for success such as technology, innovation, quality and service, combine to set us apart.

Get Price -

Crushers — Fisher Industries

You select the type of crusher—jaw, cone, gyratory, impact, or roll—and our Sales and Engineering staff will work with you stepbystep to design a custom plant that works on your toughest aggregate, recycling, or mining jobs. We can design your crushing plant with most major brands of crushers and in combination with feeders, scalping ...

Get Price