-

Cone Crushers Market |

Cone Crushers Market Growth, Trends, COVID19 Impact, and Forecasts (2021 2026) The Cone Crushers Market is Segmented by Type (, Hydraulics, and Gyratory), Offering (Mobile Crusher, Portable Crusher, and Stationary Crusher), Power Source (Electric Connection, Diesel Connection, and Dual Connection), Enduser Appliion (Mining and Metallurgy, Aggregate Processing, Construction, .

Get Price -

Cone Crusher

· Jaw crusher is usually used for primary crushing, and cone crusher is used for secondary crushing. The material of crusher plays an important role in its working efficiency and service life. However, the regular operation and maintenance are important, too.

Get Price -

Cone Crushers Market Share, Size, Growth, Opportunity and .

The global cone crushers market reached a value of US XX Million in 2020. Looking forward, IMARC Group expects the market to grow at a CAGR of XX% during . Keeping in mind the uncertainties of COVID19, we are continuously tracking and evaluating the direct as well as the indirect influence of the pandemic.

Get Price -

Cone crusher basics in 4 minutes

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

Get Price -

CH890i Cone crusher

CH890 i Cone crusher CH890i and is a technologically advanced, highcapacity cone crushers designed for crushing appliions in mines or large sized quarries. It has a hydraulically supported main shaft which is supported at both ends.

Get Price -

Cone Crusher Market 2021 is estimated to clock a modest CAGR .

Global Cone Crusher market size is projected to reach USD million by 2026, from USD million in 2020, at a CAGR of % During .

Get Price -

Cone Crusher Explained

Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always). Cone Crusher Components The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism (mechanically or hydraulically actuated).

Get Price -

Cone Crushers | McLanahan

Cone Crushers. A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point.

Get Price -

ofdisc crusher future

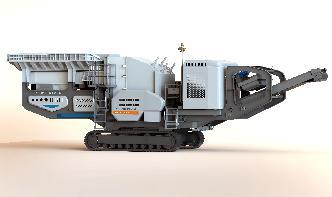

Track mounted cone crusher is one of the best crushers because it offers seamless mobility track mounted cone crusher also helps in bringing down the operational costs this can also be considered as a boon for developing countries like india or other simi,Track. Read More. future of coal crusher future of coal crusher ...

Get Price -

launches costcutting cone crusher

· launches costcutting cone crusher. has said the newest arrival in its series of cone crushers, the HP900, will have both cost and operational benefits for operators in the aggregate and mining markets. Improved technology leads to a 15% capacity increase. Infrastructure > Logistics.

Get Price -

Cone Crushers

Cone crushers have been used as primary, secondary and tertiary crushers for quite a long time. They are widely employed for crushing hard and abrasive materials in both the aggregate and mining industries. Designed especially for the hardest material types, ...

Get Price -

Raptor® Cone Crusher best in class | FL

Raptor® 500 cone crusher. Can accept up to 25% larger ores due to its m ( in) head diameter and ideal eccentric motion. Produces more material of the desired cubicity and graduation than other crushers of the same size

Get Price -

Crushers

Whether it's aggregates, mining, construction demolition, recycling or road building our jaw, cone impact crushers are ready for any job. I4c Impact Crusher 1050mm (") diameter x 1125mm (") wide Impactor

Get Price -

Cone Crusher Modelling

¾Utilization of compressive size reduction in cone crushers ¾Energy efficient crushing ¾Robust performance over total liner lifetime. 8 Quarry Academy 2005 Product Feed Power Crosssection of a cone crusher Operating Principle. 9 Quarry Academy 2005 Operating Principle. 10 Quarry Academy 2005 Operating Principle. 11

Get Price -

Cone Crusher | 1500 Maxtrak

The Powerscreen® 1500 Maxtrak cone crusher is one of the largest mobile cone crushers available on the market. Specifically developed for users requiring higher tonnage, the plant can accept an all in feed from a primary crusher to produce large volumes of aggregate.

Get Price -

Cone Crusher Market 2021 is estimated to clock a modest ...

Global Cone Crusher market size is projected to reach USD million by 2026, from USD million in 2020, at a CAGR of % During .

Get Price -

Cone Crusher

Cone crushers were originally designed and developed by around 1920 and therefore are often described as cone crushers. As the mechanisms of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the gyrating cone instead of being suspended as in larger gyratory crushers.

Get Price -

12 tips to maximize cone crusher productivity

· Avoid trickle feeding the crusher. Try not to trickle feed a cone crusher. In addition to causing poor cone crusher productivity and product shape, trickle feeding has an impact on bearing alignment within said crusher. A crusher should be operated above 40% but below rated horsepower in order to maximize cone crusher productivity and to ...

Get Price