-

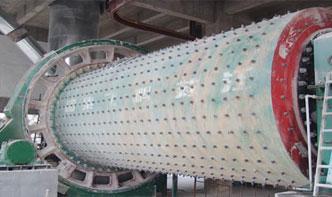

What Is a Ball Mill?

Mar 10, 2020 · It's called a "ball mill" because it's literally filled with balls. Materials are added to the ball mill, at which point the balls knock around inside the mill. How a Ball Mill Works. Ball mills work by using balls to grind materials. Materials such as iron ore, pain and ceramics are added to the ball mill. Next, the ball mill is ...

Get Price -

Trunnion Bearing Assembly Ball Mill Rod Mill

Jul 28, 2015 · Ball Mill PINION SHAFT BEARINGS. Pinion shaft bearings are of the SKF antifriction type mounted in a common twin bearing assembly. Bearings are fixed in place so that the pinion shaft of the mill is always in alignment with the drive components. Vbelt driven mills are furnished with an outboard bearing of similar construction.

Get Price -

Practical 1 : Ball Milling | TF Lab 1

Dec 23, 2013 · Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder. A ball mill is a type of grinder which consists of a cylinder. It is used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. The cylinder rotates around a .

Get Price -

Causes and solutions to common failure of ball mill ...

Jul 04, 2019 · Note: When the temperature of the bearing of the ball mill is above 70 ℃, the hand is close to the feeling of burning and burning, or when the ball is smoking, it is important to keep in mind to stop directly. The oil can be manually poured from the bearing to cool it. After the normal temperature is restored, the machine stops.

Get Price -

Ball Mill Lubriion | CIRCOR

Ball Mill Lubriion. Many mines or electric generating stations require raw minerals to be ground and pulverized for final processing. This process can be achieved through one of the different types of ball mills used – SAG Mill‚ Ball Mill‚ Rod Mill and Double Ended Ball Mill included.

Get Price -

Ball mill trunnion

Ball mill trunnion. The ball mill trunnion is a key part to support and connect the cylinder, and is also the inlet and outlet channel of the material. CHAENG adopts highstrength steel and unique heat treatment technology, which makes ball mill trunnion have high hardness and strong impact resistance.

Get Price -

Ball Mills | Industry Grinder for Mineral Processing ...

Ball Mills 【Capacity】 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max Feeding Size】 <25mm 【Discharge Size】 【Types】Overflow ball mills, grate discharge ball mills 【Service】 24hrs quotation, custommade parts, processing .

Get Price -

Baltec

Ball Screws. Ball screws are very similar to ball bearings in that they generally use either chrome steel or type 440C hard stainless steel. A peculiarity of ball screws is that they typically have a load ball and the next ball is a .001inch undersized spacer ball, and so on.

Get Price -

Sliding Shoe Bearing Ball Mill Skf

Rolling bearing ball mill youtube apr 2015, what is the working principle of ball millwhat are its features ball mill working principle when the ball mill works, motor and speed reducer transmit torque large ball mills adopt pitot pressure or hydrostatic bearings 3the hydrostatic sliding shoe bearing arrangement works on the.

Get Price -

Ball End Mills | Travers Tool

Ball End Mills have a hemispherical tip used to machine rounded details, such as the metal bearing grooves found in machines. Also called Ball Nose End Mills, they are used extensively in manufacturing tools dies, and machining complex three dimensional contours with a smooth finish. Ball End Mills are very durable, and come with an array of surface coatings tailored for milling a wide range ...

Get Price -

Ceramic Ball Mill Relining and Refurbishing

If the mill is old and has babbitted bearings we can machine the trunnions and replace the old friction bearings with sealed roller bearings. We can also rebuild or replaced drive components including ring pinion gears and reducers and motors. Repair and Refurbishing Services: We reline all sizes of ceramic lined ball mills or pebble mills.

Get Price -

Lubriion for Ball Mills

Bearing Oil Externally Cooled (, water jackets) (JetLube Paragon Mill Bearing Oil EP) For: Enclosed conditions such as a bearing housing on Rotary Kilns, Rotary Dryers and Ball Mills.

Get Price -

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

May 30, 2016 · The ultimate crystalline size of graphite, estimated by the Raman intensity ratio, of nm for the agate ballmill is smaller than that of nm for the stainless ballmill, while the milling ...

Get Price -

Use Cement Ball Mill Grinding Cement Clinker | Cement Ball ...

According to the needs of different customers, there are two types of cement ball mill: openflow mill and circularflow mill. The φ×13 cement ball mill with doublesliding structure solves the problem of the similar product "the discharge end slide bearing temperature is too high to operate continuously", which ensures the equipment can run continuously and stably for a long time .

Get Price -

High vibration on the ball mill drive train A and B | AMP ...

Aug 25, 2016 · High vibration on the ball mill drive train A and B. We are experiencing high vibration on our dual drive ball mill. The high vibration is on the motor DE bearing on axial direction. Dominant frequency is girth and pinion gear mesh. See attached spectrums and trends. Gearbox holddown bolts are breaking due to high vibration.

Get Price -

Ball Mill Bearing Material | Crusher Mills, Cone Crusher ...

Ball Millone important stone crusher and grinding machine. Ball mill is widely used for milling various kinds of ores or rocks in metal and nonmetal mining and building material main bearing of the ball mill .

Get Price -

B Ball Mill Inspection | Bearing (Mechanical) | Mill ...

Ball Mill Servicing Bearings. No. Work to be performed Frequency Comments 1 If necessary, adjust or replace the Yseal () every 26 weeks 2 Check all oil supply connections inside the housing ...

Get Price -

Energy efficient cement ball mill from FL

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the FL ball mill .

Get Price -

Ball Mill Bearing Suppliers Factory Directly, Bearing ...

Ball mill bearing suppliers and factory directly, bearing manufacturer the ball mill Bearings play a role of supporting dynamic and static load in the ball mill and It is a key structural component in the ball mill. Our factory process, repair and retread all kinds of ball mill bearings according to .

Get Price -

Is it possible to use balls (that used in bearings) for ...

Above points about ball and jar material are certainly valid. I would say, however to give it a try. First time you do the milling remove samples at various times, and run the mill for much longer ...

Get Price -

reasons for ball mill bearings failure

Ball mill working principle,Ball Mill for beneficiation product line. the existing ball mill starting mode and the control mode is not saving, though ... when the existing ball mill force of the impact is very large, so the ball mill bearings ... voltage drop, can also cause severe tripping and other equipment failures,...

Get Price -

Type selection and matching of rolling bearings of ball mill

Type selection and matching of rolling bearings of ball mill. Compared with sliding bearing,the rolling bearing of ball mill possesses advantages of low friction factor and force saving,rolling bearing is widely used at ball mill by many manufacturers.

Get Price