-

The Schoefer Kilns Historical Marker

Jul 05, 2015 · It is made by burning various minerals in a kiln at intensive heat to produce clinker. The upright dome kiln was the first type used in America. An improvement was the Schoefer vertical kiln with chambers for heating burning and cooling the material. The kiln was in continuous production except when closed for repairs. Bituminous coal served as ...

Get Price -

clinker photos on Flickr | Flickr

The former cement and clinker factory of the ENCI quarry is shown here, together with its giant smokestack on the left. Clinker, semifinished cement, was produced by "heating limestone (calcium carbonate) with small quantities of other materials (such as .

Get Price -

Cement has a carbon problem. Here are some concrete ...

Nov 20, 2019 · Avalon Studio / Getty Images. Maddie Stone ... would be to find cleanerburning fuels that are capable of heating a cement kiln. ... the kiln to form a substance known as "clinker," which is ...

Get Price -

USA

A new process for burning cement clinker consisting of a rotary kiln, a raw material suspension preheater comprising multistage cyclone heat exchangers, and a fluidized calciner having a separate heat source is provided. This process improves the allover decarbonizing rate of raw materials fed into the rotary kiln remarkably by extracting a part of the raw materials from at .

Get Price -

Clinker: reactions in the kiln

Reactions which take place as the feed passes through the kiln are reviewed below. They can be considered under three broad headings: Decomposition of raw materials temperatures up to about 1300 °C. Alite formation and other reactions at 1300 C1450 °C in the burning zone. Cooling of the clinker.

Get Price -

clinker microscopy

A considerable amount can be gleaned from the clinker microstructure about how the raw feed was prepared, how the temperature profile in the kiln affected the crystal growth, how quickly the clinker was cooled by secondary air after leaving the burning zone and before falling into the cooler and even about how the cement made from this clinker ...

Get Price -

Top PDF Cement Kiln Liquid Phase

For instance, a regular clinker at 1450 ºC has a viscosity of /m 2 . Adding 2% SO3 to the clinker reduces that viscosity to /m 2. Oversulfated clinkers are usually dusty as a consequence. Extreme caution should be exerted when insufflating calcium chloride into the burning zone as a way to reduce alkali in the clinker.

Get Price -

Cement | Hasle Refractories

Kiln Hood: High abrasion from high speed hot clinkers and chemical attack from gases from burning of fuel. 12 Burner Pipe: Severe abrasion (from hot and highspeed clinker dust) and chemical attack.

Get Price -

Pyroscan Kiln Burner Thermal Monitor

Pyroscan Kiln Burner Thermal Monitor. Pyroscan is a new generation Gigabit Ethernet pyrometric camera for monitoring the inside of rotary kilns or of clinker coolers. This camera enables the detection of any changes on the combustion and the visualization of clinker fall. The operator can instantly see impacts of burner adjustments, variation ...

Get Price -

Cement kiln

A rotary kiln of 6 x 100 m makes 8,000–10,000 tonnes per day, using about tonnes of coal fuel for every tonne of clinker produced. The kiln is dwarfed by the massive preheater tower and cooler in these installations. Such a kiln produces 3 million tonnes of clinker per year, and consumes 300,000 tonnes of coal.

Get Price -

Qatrana

Portland Cement is made primarily from a combination of a calcareous material, such as limestone or chalk, and of silica and alumina found as clay or manufacturing process consists essentially of grinding the raw materials into a very fine powder, mixing them intimately in a predetermined proportion, and burning them in a large rotary kiln at a temperature of about 1400 ˚C (2550 ˚F).

Get Price -

Hot Clinker Tumble And Flow Inside Of Rotary Burning Kiln ...

Description: Industrial production process of cement clinker. Oven rotates and hot glowing clinker tumble and flow inside of rotary burning kiln.

Get Price -

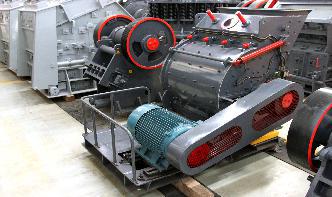

m Rotary Kiln BL

Buy m Rotary Kiln BL, Rotary kiln, 1) Simple structure, 2) Energysaving, 3) Environmental protection, 4) ISO9001:2008 and 3C ... Cement rotary kiln cement clinker burning mainly used, the production of dry and wet cement kiln cement kiln production of two egories. ... Pictures of rotary kiln: Product Items Relevant with m ...

Get Price -

1 refa1 clinker burning, coating form, flame

Nov 02, 2012 · Nov 02, 2012 · 21. Clinker burning 1)Radiation of heat from flame to refractory Heat 2)Conduction of 1400 deg c heat from refractory to charge 3)Convection of 1900 1350 deg c heat from 1450 ded c particle to particle while rpm 1500 deg increases the rate of convection Higher rpm improves the thermal distribution,better heat exchange between ...

Get Price -

Tyres as an alternative fuel

Mar 03, 2011 · The use of tyres as a fuel in cement production influences kiln operation and clinker composition. Sulphur Due to the high sulphur content the circulation of volatile salts increases depending on the sulphur content of the substituted coal and therefore the coating tendencies in the area of the kiln inlet, riser and lower cyclones also ...

Get Price -

ash rings in coal burning cement kilns

Ash Rings In Coal Burning Cement Kilns. Coal ash properties amp impact on clinker quality,coal ash properties impact on clinker quality. dear ted. is there any good impact when we use lignite as a fuel instead of other solid fuels with low ash content. as have seen on net that flyash from lignite gives lime in the range of 20%. if it is 20% than this flyash can be used as a source of lime ...

Get Price -

Development of Conventional Controller Based on Image ...

In the cement factories, a rotary kiln is a pyroprocessing device that is used to raise the temperature of the materials in a continuous process. Temperature monitoring is an essential process in the rotary kiln to yield high quality clinker and it has been implemented using various image processing this paper we are measuring and controlling the temperature of rotational kiln ...

Get Price -

(PDF) CFD MODELING OF A CEMENT KILN WITH MULTI CHANNEL ...

This paper deals with the detailed CFD modelling carried out for a full scale rotary cement kiln with multi channel coal burner. The study includes developing and combining the models of gassolid flow, modelling of pulverized coal combustion and

Get Price -

Kiln Zone !

Aug 09, 2008 · The burning zone of a cement kiln is the hottest part of the kiln, under the flame where the final combination into the clinker minerals takes place. Behind that burning zone is the upper transition zone where the temperatures is rising to that in the burning zone. In front of that burning zone where the clinker has been formed and is about to ...

Get Price -

Recognition method of cement rotary kiln burning state ...

Firstly, the flame image of the clinker burning core region in the rotary kiln was obtained by using advanced vision detection technology, and then the OtsuKmeans image segmentation method was used to realize the effective segmentation of the target region of a flame image.

Get Price -

Process and quality optimization in cement plant.

Jul 31, 2020 · As the burning condition determines the cement quality, the "C" index can be used directly for predicting the cement properties. For example, during the production of the clinker with"C" index ranging from to (Table 3), the kiln atmosphere was very dusty, and the cement produced showed abnormal properties.

Get Price